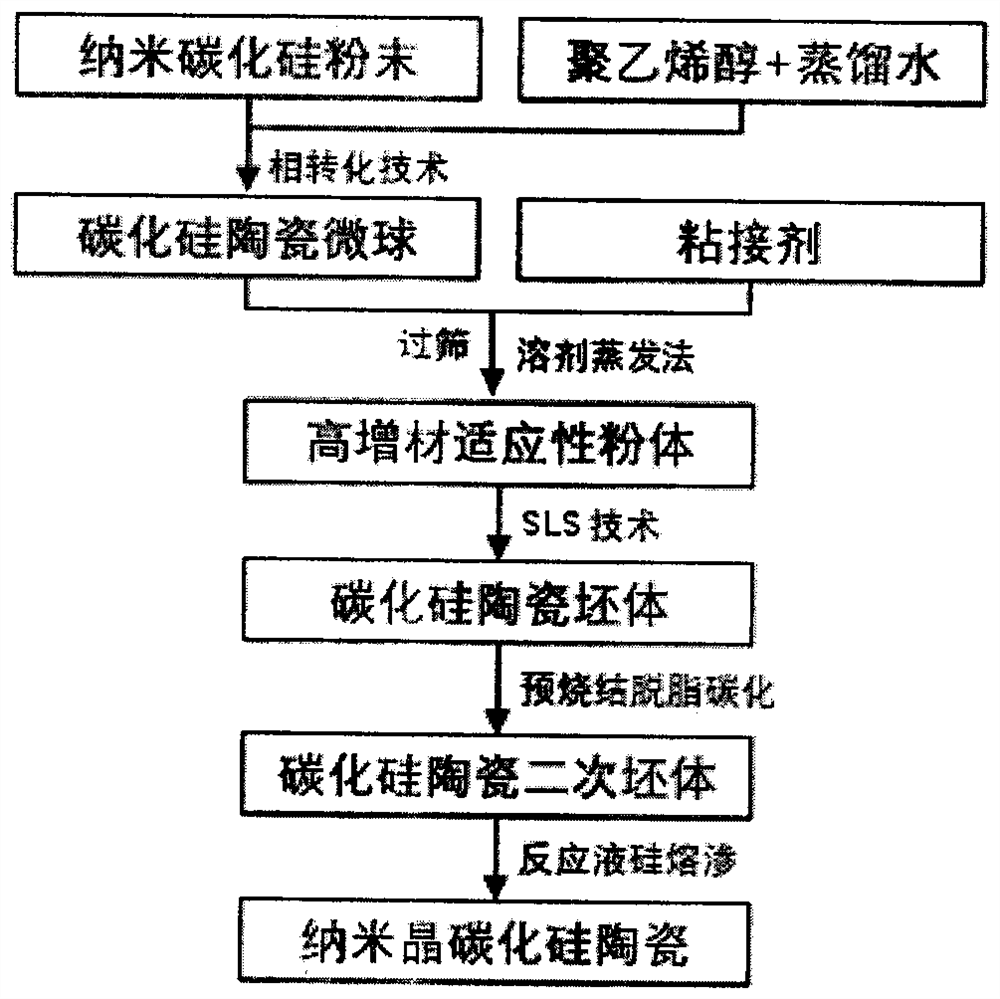

Method for preparing nanocrystalline silicon carbide ceramic by SLS (selective laser sintering) based on phase inversion microspheres

A technology of silicon carbide ceramics and nano-silicon carbide, which is applied in the direction of ceramic molding machines, manufacturing tools, and additive processing, can solve the problems of large porosity, high particle size distribution and sphericity requirements, and low strength of the green body. Achieve the effect of uniform grain size distribution, speed up liquid silicon infiltration process, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The average particle diameter is 40nm and the nano-silicon carbide ceramic powder with a mass fraction of 70%, polyvinyl alcohol with a mass fraction of 4%, and distilled water with a mass fraction of 26% are added into a ball mill and mixed uniformly to prepare a slurry;

[0027] (2) Perform spray ionization granulation on the slurry configured in step (1), and the tiny liquid droplets that are sprayed and ionized enter the curing pool to undergo cross-linking and curing reactions to form ceramic particles. The solution in the curing pool is glycerol and boric acid, wherein The massfraction of boric acid is 10%;

[0028] (3) Wash the ceramic particles prepared in step (2) with an alcohol solution and dry them naturally in the atmosphere, then sinter and degrease the ceramic particles in a muffle furnace, the temperature is controlled at 1000°C, and the heating rate is controlled at 10°C / min;

[0029] In this example, silicon carbide ceramic microspheres with a pa...

Embodiment 2

[0036] (1) adding nano-silicon carbide ceramic powder with an average particle diameter of 50 nm and a mass fraction of 65%, polyvinyl alcohol with a mass fraction of 5%, and distilled water with a mass fraction of 30% in a ball mill and mixing uniformly to prepare a slurry;

[0037] (2) Perform spray ionization granulation on the slurry configured in step (1), and the tiny liquid droplets that are sprayed and ionized enter the curing pool to undergo cross-linking and curing reactions to form ceramic particles. The solution in the curing pool is glycerol and boric acid, wherein The massfraction of boric acid is 12%;

[0038] (3) Wash the ceramic particles prepared in step (2) with an alcohol solution and dry them naturally in the atmosphere, then sinter and degrease the ceramic particles in a muffle furnace, the temperature is controlled at 1200°C, and the heating rate is controlled at 5°C / min;

[0039] In this embodiment, silicon carbide ceramic microspheres with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com