A kind of preparation method of environment-friendly asphalt modifier

A kind of asphalt modifier and modifier technology, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of poor environmental adaptability and environmental pollution of modified asphalt, to avoid quality fluctuations, improve anti-rutting performance, The effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

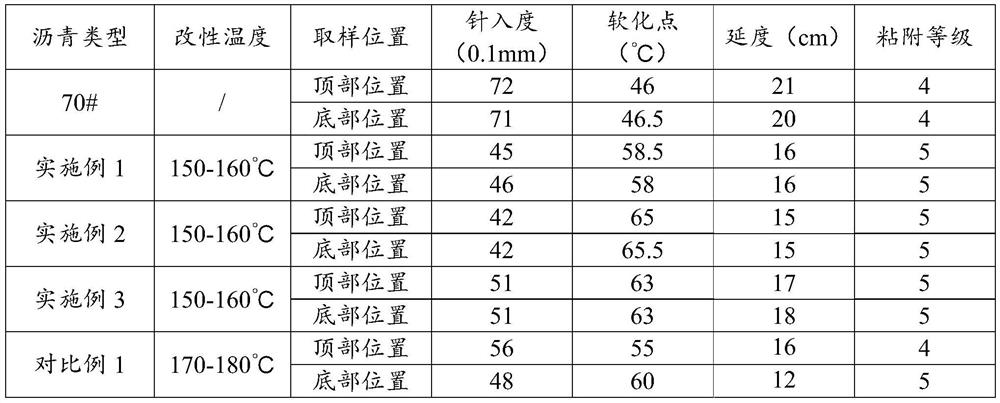

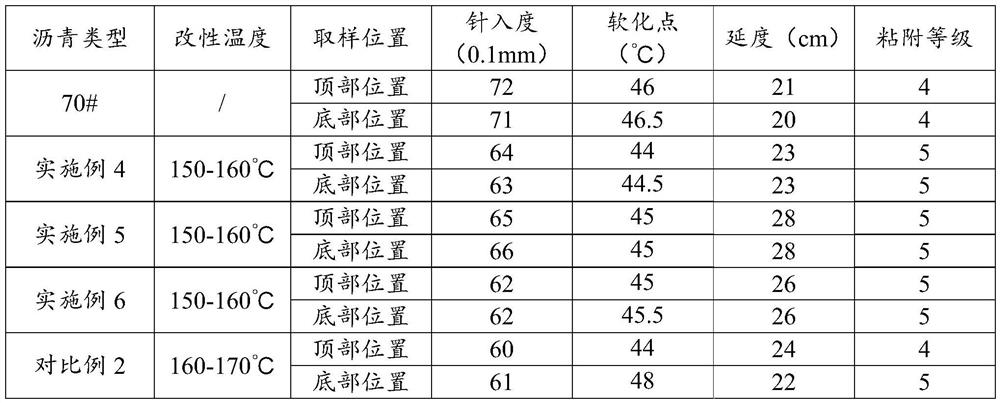

Embodiment 1

[0031] Environmentally friendly asphalt modifier - Preparation of Core material: weight, 80 parts of natural asphalt weighed, 3 parts of sodium polyacrylate, dodecyl trimethyl ammonium chloride, 5 parts of a titanate coupling agent and 4 parts of magnesium-based coupling agent, quick lime and slaked lime were 8 parts, by grinding to give a particle size of 300 mesh core material.

[0032] Environmentally friendly asphalt modifier - Preparation of hot melt-type packaging film: weight, weighed 70 parts polypropylene, 10 parts polyethylene, 5 parts of stearic acid, 2 parts of a polyamide, polyethylene - vinyl acetate 13 parts, by blending, granulation, blown film molding process to obtain a hot melt packaging film.

[0033] Finally, the above-described hot-melt mass core wrap packaging material, a hot melt packaging operation core wrap material, the mass ratio of the core material and the packaging film is 5: 1, the use of powder filling packaging machine to package hot melt membrane...

Embodiment 2

[0036] Environmentally friendly asphalt modifier - Preparation of Core material: weight, weighed 65 parts of natural asphalt, 5 parts of triethanolamine, cetyl trimethyl ammonium chloride 7 parts of a titanate coupling agent, and 6 parts of zirconium-based coupling agent, a total of 10 parts of hydrated lime and cement, 7 parts of a polystyrene butadiene copolymer, obtained by grinding a particle size of the core material 280 purposes.

[0037] Environmentally friendly asphalt modifier - Preparation of hot melt-type packaging film: weight, weighed 75 parts of polypropylene, polyethylene 5 parts, 7 parts of stearic acid, 5 parts of polyamide, polyethylene - vinyl acetate 8 parts, by blending, granulation, blown film molding process to obtain a hot melt packaging film.

[0038] Finally, the quality of hot melt-type package set packaging film core material, a hot melt packaging operation quality core wrap material, the core material and packaging film ratio of 10: 1, using the powder...

Embodiment 3

[0041] Environmentally friendly asphalt modifier - Preparation of Core material: weight, weighed 73 parts of natural asphalt, triethanolamine 4 parts of stearyl trimethyl ammonium chloride 6 parts of magnesium and zirconium-based coupling agent coupling agent of 5 parts, cement and lime 9 parts, 3 parts of polystyrene-butadiene copolymers, are ground to give a particle size of 350 mesh core material.

[0042] Environmentally friendly asphalt modifier - Preparation of hot melt-type packaging film: weight, weighed 73 parts of polypropylene, polyethylene 8 parts, 6 parts of stearic acid, 3 parts of polyamide, polyethylene - vinyl acetate 10 parts, by blending, granulation, blown film molding process to obtain a hot melt packaging film.

[0043]Finally, the quality of hot melt-type package set packaging film core material, a hot melt packaging operation quality core wrap material, the core material and packaging film ratio of 20: 1, using the powder filling packaging machine to packag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com