Buttress type ecological retaining wall structure

An ecological retaining wall and buttress type technology, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as inability to use, thankless, and inability to beautify the environment, so as to reduce the impact and solve the problem. Effects of the stagnant water problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

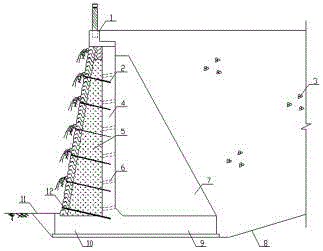

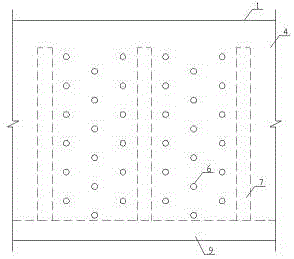

[0015] Such as figure 1 -2, a buttress-type ecological retaining wall structure, the buttress-type retaining wall includes a buttress vertical plate 4, the lower end of the buttress vertical plate 4 is provided with a buttress bottom plate 9, and the buttress bottom plate 9 can be lined on the mud surface Next, the buttress bottom plate 9 is a part of the front toe 10 of the buttress bottom plate. The length of the buttress bottom plate 9 is designed according to the situation of the buttress type retaining wall above. If the length of the buttress bottom plate 9 is too short, it is impossible to make the ecological building The block structure is safe and reliable, and the rear of the front toe 9 of the buttress bottom plate is the excavation side slope line 8 of the foundation pit. The buttress rib 7 connects and reinforces the shore side of the buttress vertical plate 4 and the buttress bottom plate 9, and the water side of the buttress vertical plate 4 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com