Double-layer corrugating overlapped foam concrete composite color steel plate and machining method

A foamed concrete and color steel plate technology, applied in the direction of roof covering layer, roofing with flat/curved panels, roofing, etc., can solve the problems of low strength, high consumption of thermal insulation materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

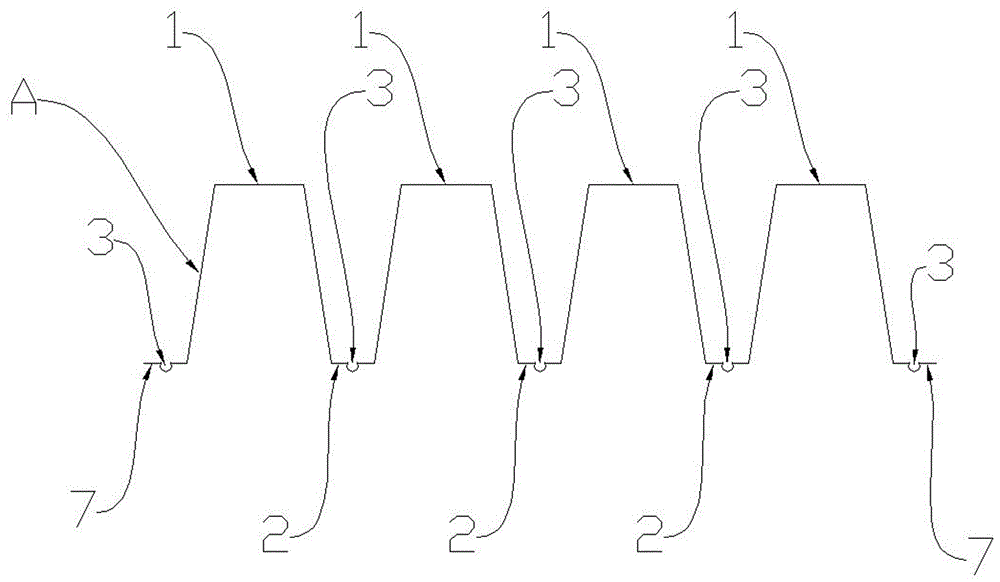

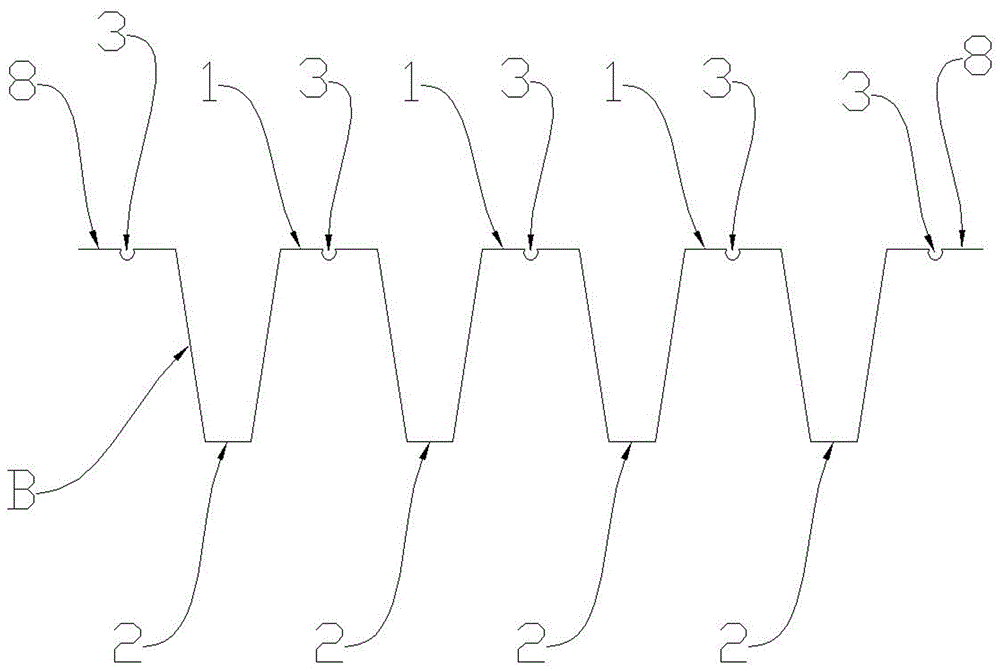

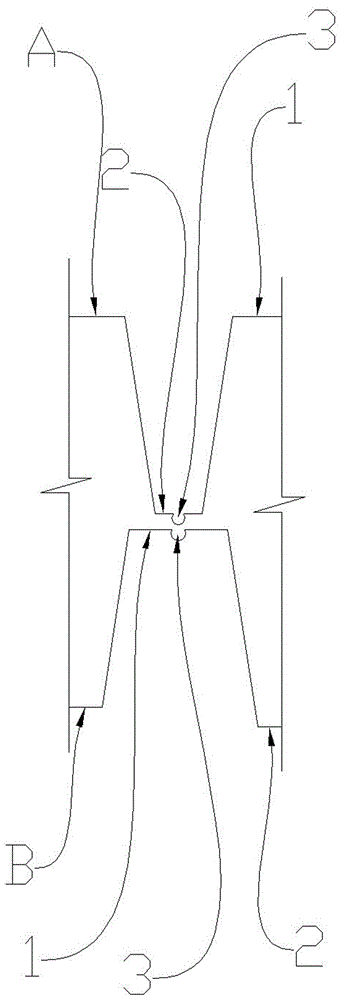

[0012] The content of the invention has described the specific implementation of the present invention in detail, and it will not be repeated here; it needs to be explained: After the upper plate A and the lower plate B are connected, a plurality of cavities 4 are formed, and the plurality of cavities 4 greatly increase the rigidity and stability of the color steel plate. Intensity, if foamed concrete is injected into multiple cavities 4, the overall strength and local strength of the color steel plate will be further increased. This local strength can prevent roof installation or maintenance personnel from trampling the color steel plate locally; the present invention only needs to place the upper plate The groove of the lower corrugation 2 of A is filled with thermal insulation material 5, which not only reduces the weight of the entire color steel plate but also saves a large amount of thermal insulation material; the foamed concrete has light weight, certain strength, and ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap