Sliding door and window

A technology for sliding doors, windows and door leaves, applied in the field of doors and windows, can solve the problems of affecting the service life of door leaves, complicated installation of sliding doors and windows, uneven force on the upper slide rail, etc., so as to prolong the service life, realize the effect of heat insulation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

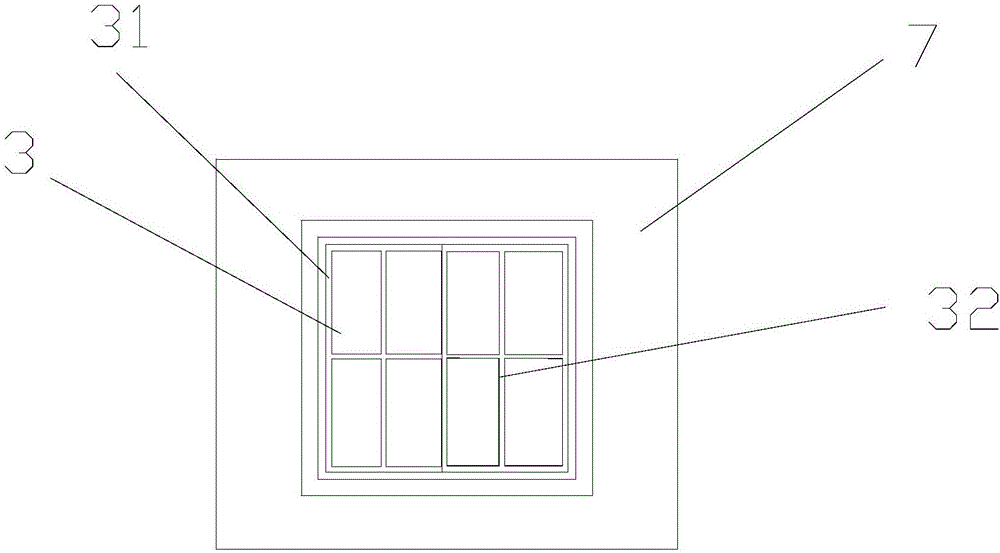

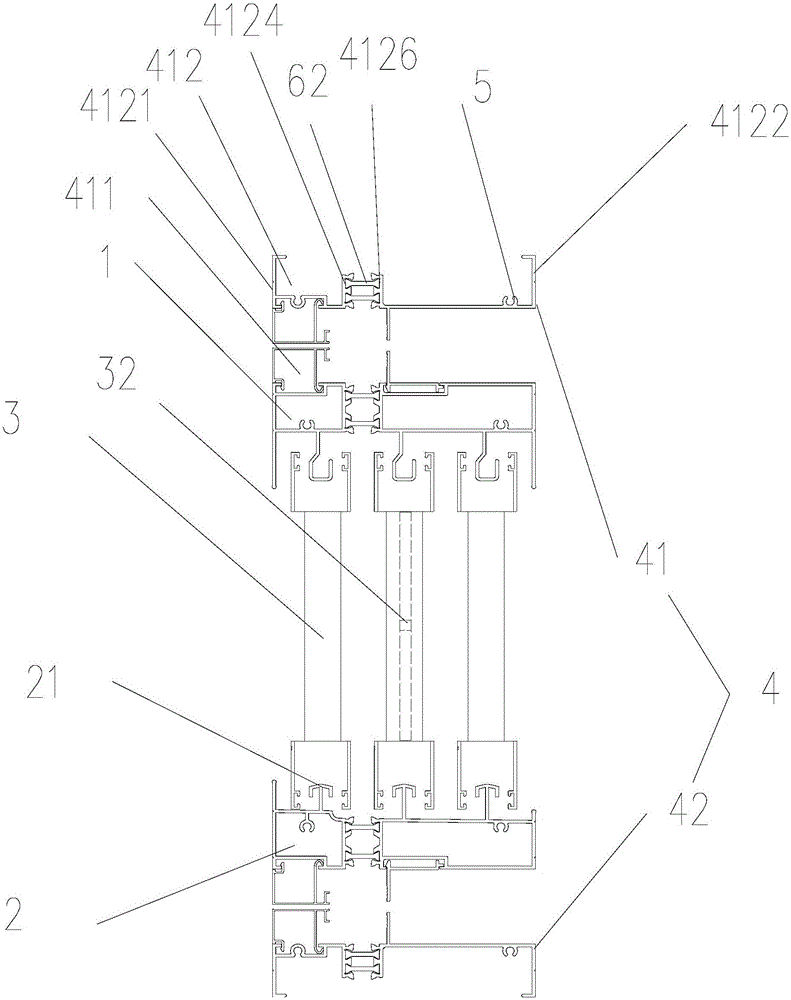

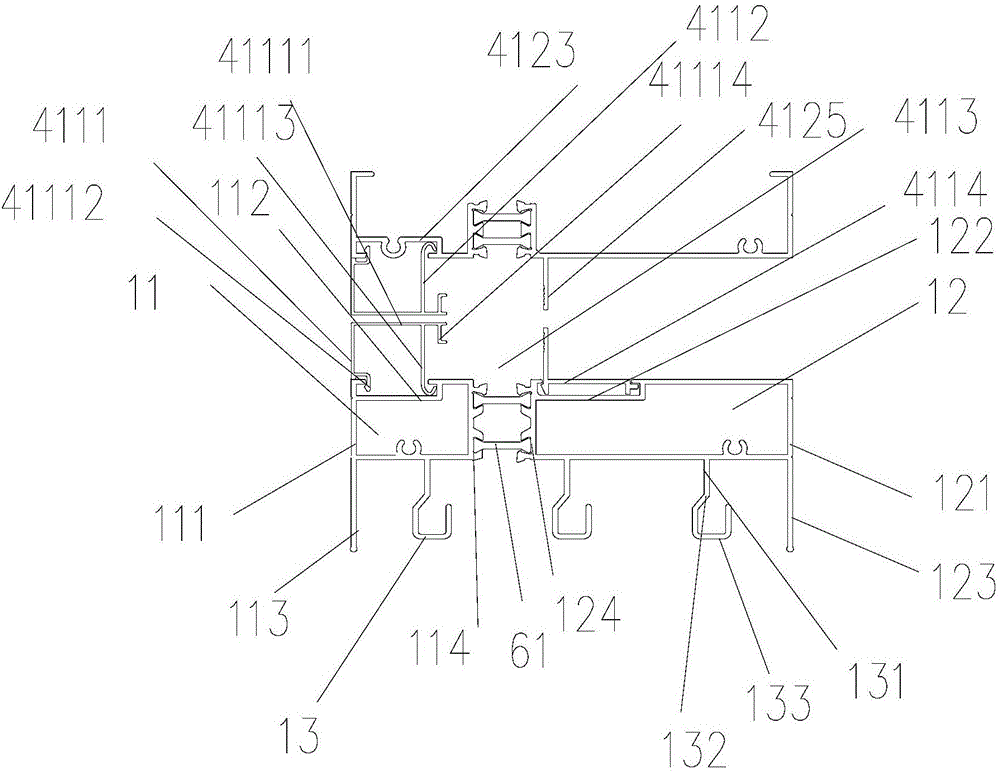

[0033] Such as Figure 1-5As shown, a sliding door and window of this embodiment has a simple structure and is easy to install, and includes an upper rail 1, a lower rail 2, and a glass door leaf 3; the upper rail 1 is located above the glass door leaf 3, and includes a left rail 11 and a right rail 12; The left rail 11 includes a first rectangular cavity 111 with a first groove 112 on the left side of the upper end. The left frame of the first rectangular cavity 111 extends downwards and is provided with a left support 113. The outside of the right frame of the left rail 11 has two second grooves. A heat insulating strip slot 114; the right rail 12 is arranged in parallel on the right side of the left rail 11, including a second rectangular cavity 121 with a second groove 122 at the upper end, and the right frame of the second rectangular cavity 121 extends downwards The right support 123 has two second heat insulation strip slots 124 on the outside of the left frame, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com