Aerogel heat insulating oil pipe

A heat-insulating oil pipe and aerogel technology, which is applied in the direction of drilling pipe, casing, drilling equipment, etc., can solve the problems of few applications in the petroleum industry, no application in steam injection wellbore heat insulation, and low thermal conductivity, etc., to achieve Improve economic development benefits, improve application timeliness, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

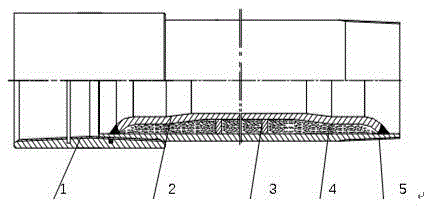

[0016] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0017] according to figure 1 , an airgel heat-insulated oil pipe, comprising an inner pipe 2 and an outer pipe 5, the outer pipe is sheathed outside the inner pipe and an airtight heat-insulating ring cavity 4 is formed between the inner pipe and the outer pipe, the heat-insulating ring The cavity is filled with heat insulating material. The heat insulating material adopts airgel. At least one centralizing ring 3 is arranged in the cavity of the heat insulating ring. Both ends of the inner tube are trumpet-shaped. The left end of the inner tube is welded to the inner wall of the left end of the outer tube, and then the right end of the inner tube is heated and elongated according to the design expansion rate and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com