Downhole string cutting and fishing integrated tool and its construction method

A downhole pipe string and tool technology, which is applied to the downhole pipe string cutting and salvage integrated tool and its construction field, can solve the problems that the cutting pipe string and the salvaging pipe string cannot be realized, increase the operation cost, reduce the operation efficiency, etc., so as to improve the oil field. Economic development benefits, reducing the number of trips and trips of the pipe string, and improving the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

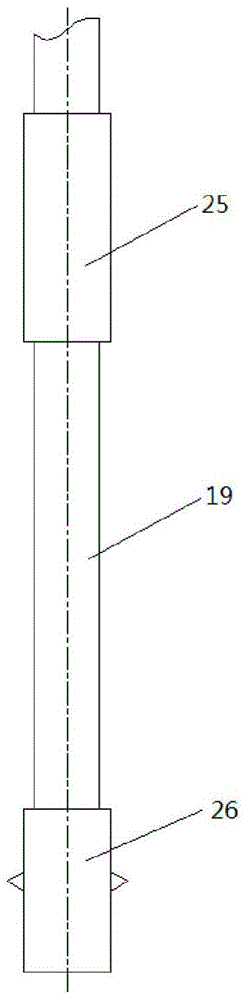

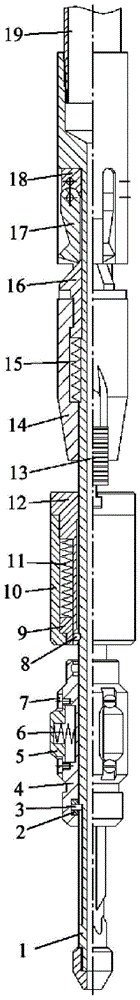

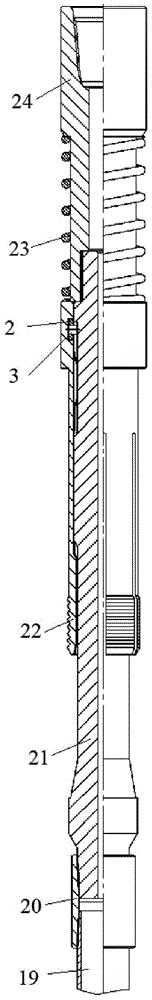

[0028] The present invention is described in detail below in conjunction with accompanying drawing and does not limit protection scope of the present invention, see figure 1 , figure 2 and image 3 , the downhole string cutting and fishing integrated tool includes a cutting device 26 and a fishing spear 25, the cutting device 26 is provided with a cutting mechanism, a centering mechanism and a center rod 1, the cutting mechanism and the centering mechanism are installed on the center rod 1, and the fishing spear 25 is provided with There are fishing rods 21 . The cutting device 26 is connected with the fishing spear 25 through the positioning oil pipe 19. The center rod 1 of the cutting device 26 is provided with a seat sealing and unsealing reversing track, and a seat sealing mechanism is also installed between the cutting mechanism and the righting mechanism. It is connected with the cutting mechanism through slips 13; the seat seal mechanism includes slip sleeves 12, sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com