Engine cooling water circulating device

A cooling water circulation and engine technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of messy trend, water leakage, easy aging of hoses, etc., achieve orderly layout, avoid high temperature resistance, and solve The effect of poor exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

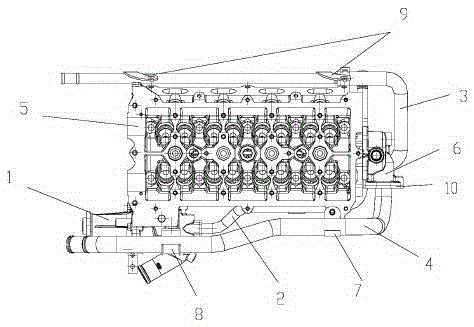

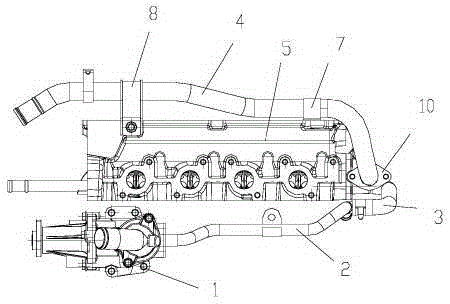

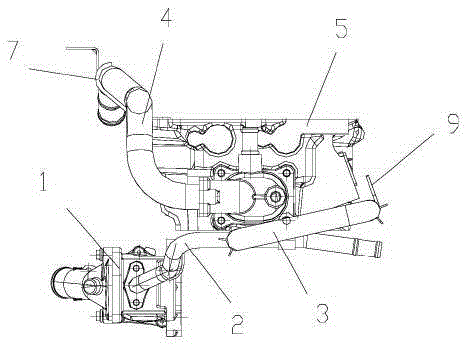

[0016] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 bottom view, image 3 for figure 1 Right view, as shown:

[0017] The engine cooling water circulation device of this embodiment includes a water pump 1, a warm air return pipe 2, a water inlet pipe 3 and a water outlet pipe 4. The warm air return pipe 2 is communicated with the water pump 1, and the water inlet pipe 3 is provided in the engine cylinder. The air intake side of the body 5 is connected with the warm air return pipe 2, and the water outlet pipe 4 is arranged on the exhaust side of the engine cylinder block 5 and is connected with the engine water outlet chamber 6 through the flange plate 10; the engine water outlet chamber is connected by the engine cylinder block. 5. The chamber body formed by the water outlet end forms a flange structure at the connection joint between the water outlet chamber and the water outlet pipe 4.

[0018] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com