A quasi-zero stiffness vibration isolation device

A zero-stiffness, vibration-isolation technology, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, spring/shock absorber, etc., can solve the injury, increase the driver's back disease, and there is no good isolation method for low-frequency vibration etc. to achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

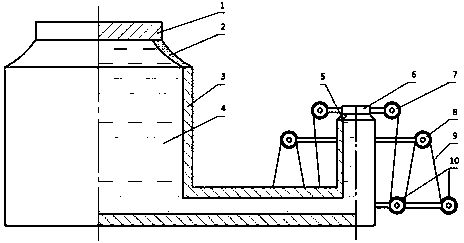

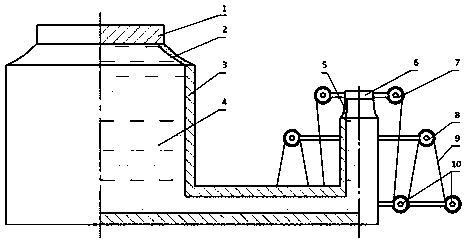

[0023] The design idea of the present invention is illustrated below by accompanying drawings.

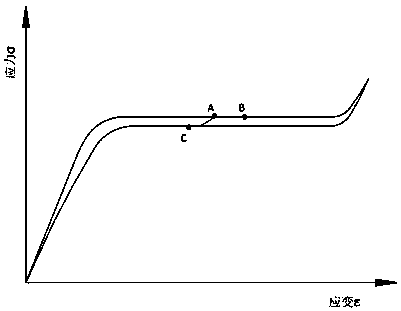

[0024] Such as figure 1 As shown, point A is the position point on the hysteresis curve of the shape memory alloy wire after pre-stretching treatment, point B is the position point reached by the alloy wire after the strain continues to increase based on the pretreatment at point A, and point C is the The point where the strain decreases based on the pre-stretched length at point A. It can be seen that both A and B are on the upper platform of the hysteresis curve, and the ordinate (stress) remains unchanged; while C is on the lower platform of the hysteresis curve. Since the width of the hysteresis curve is extremely narrow, the upper and lower platforms almost overlap, so A and C The ordinate (stress) of is almost the same. To sum up, in the superelastic range of this shape memory alloy wire, no matter the strain increases or decreases, the restoring force remains basically u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com