Directional Swirl Adaptive Hydraulic Mounting Shock Absorber

A liquid resistance mount and shock absorber technology, which is applied in the direction of liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as reducing the service life of equipment, liquid interruption, and corrosion of parts, so as to improve the application , Small dynamic stiffness, not easy to harden at high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

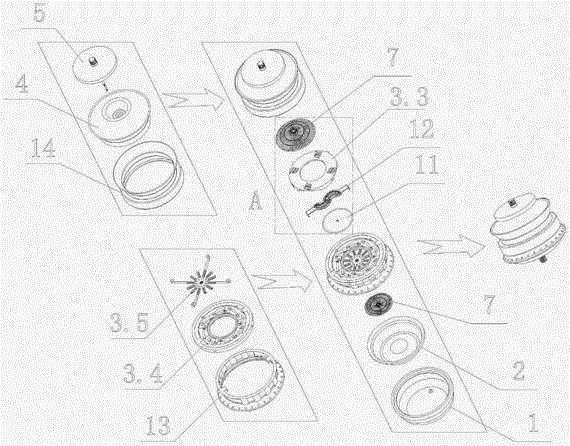

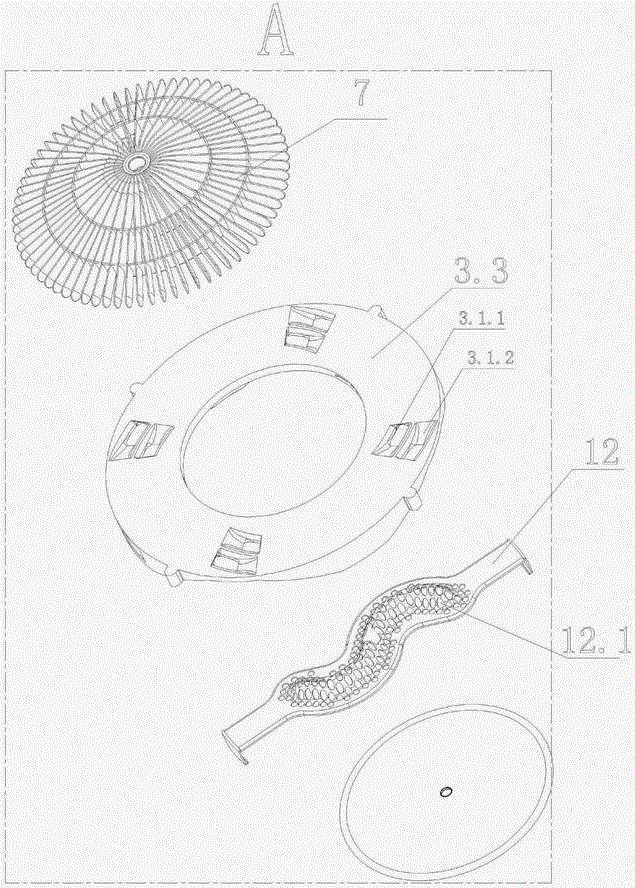

[0037] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

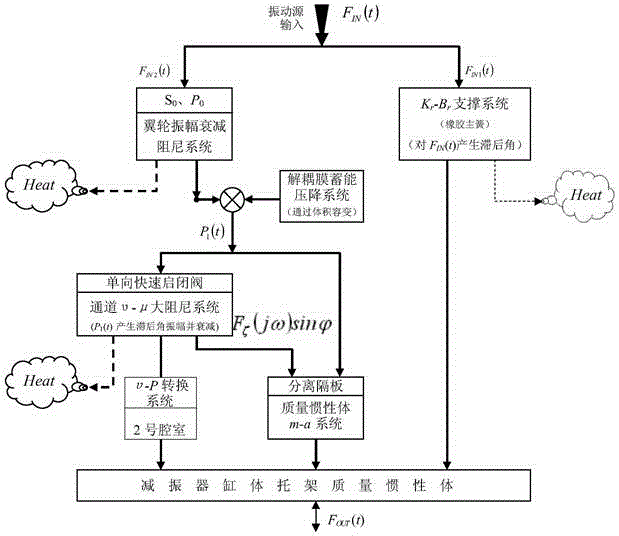

[0038]The "directional swirl flow" in the present invention refers to a single direction of circulation along the hydraulic chamber, that is, a directional swirling flow. "Adaptation" in the present invention refers to the accelerated directional swirl of the conversion mechanism that is proportional to the increase of the amplitude and vibration frequency, so the frictional heat energy converted by the swirl is also greater, that is to say, with the increase of the amplitude and vibration frequency The higher the vibration frequency, the higher the heat generated and the more obvious the shock absorption effect, which can prevent the hardening phenomenon, so the system is defined as an "adaptive" damping system.

[0039] As shown in the figure, the present invention provides a directional swirl self-adaptive fluid resistance suspension shock abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com