Steam safety valve

A safety valve and steam technology, applied in the direction of safety valve, lifting valve, balance valve, etc., can solve the problems of easy deflection of the valve disc, affecting the sealing performance of the valve, and high center of gravity of the valve, so as to improve the sealing performance of the valve, increase the service life, The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

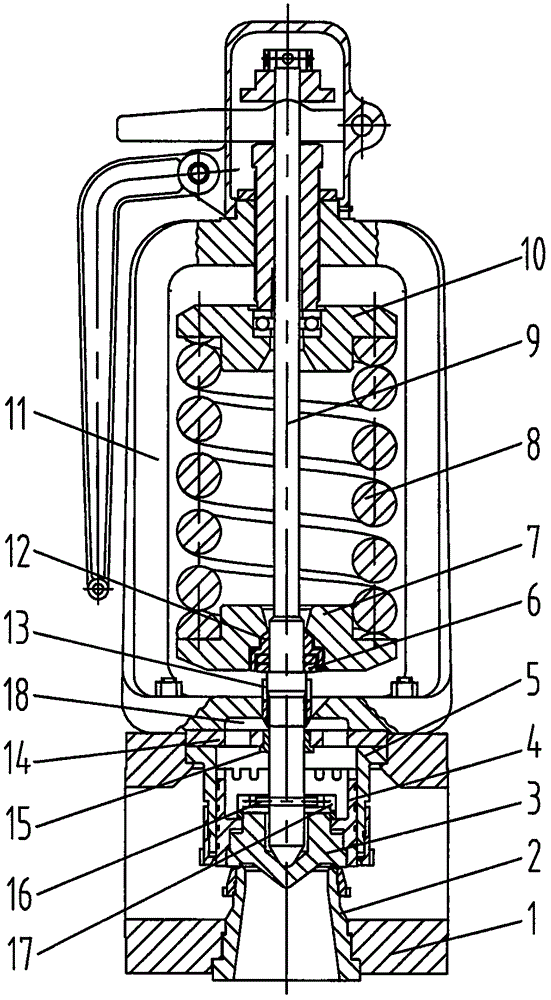

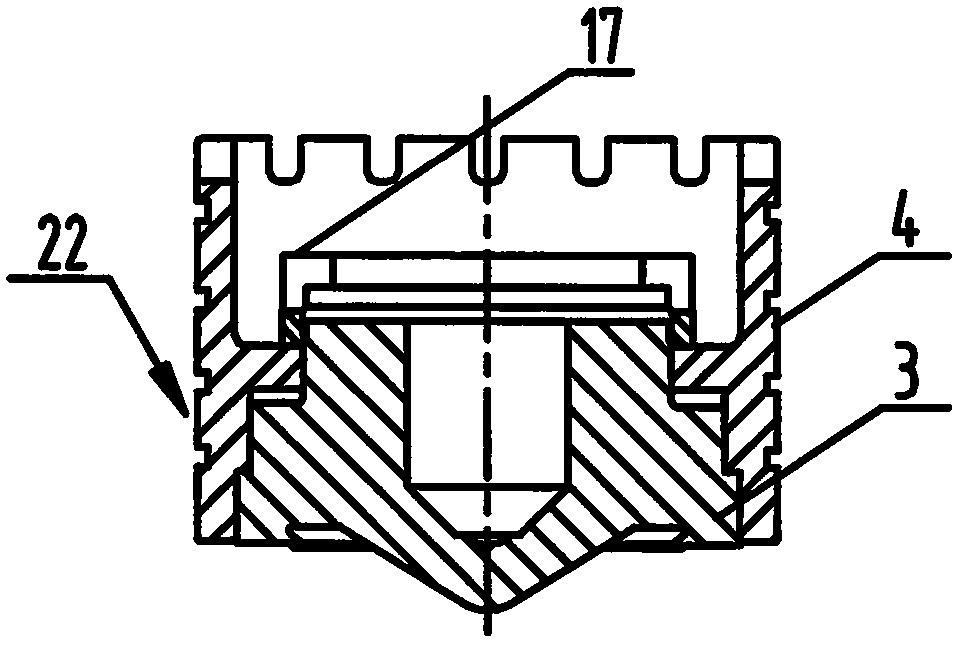

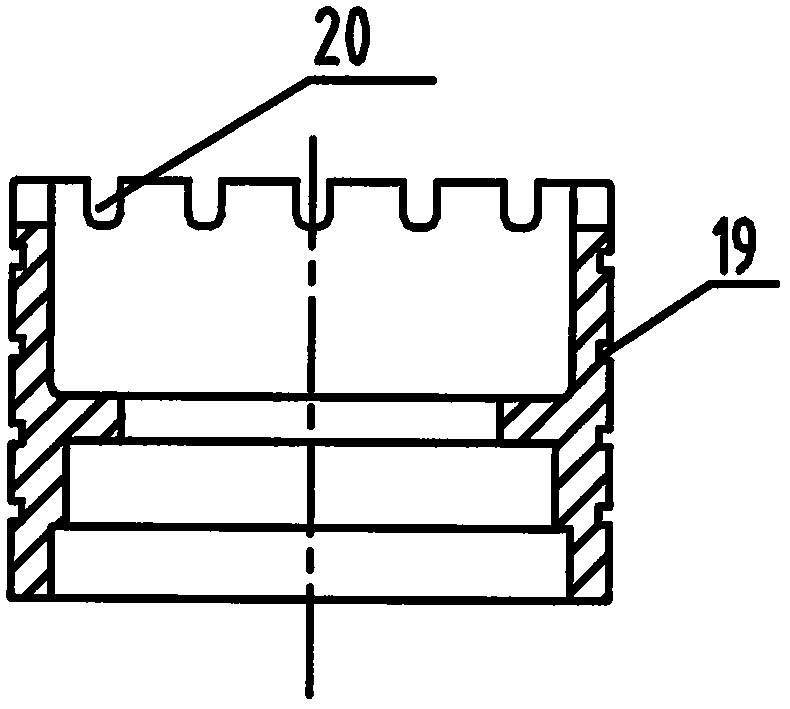

[0020] exist Figure 1 to Figure 5 In the shown embodiment, the valve body (1) is threadedly connected to the valve seat (2), and the valve disc (3) and the valve disc sleeve (4) are fixed by lock nuts (17) to form a valve disc sleeve assembly (22 ), and move up and down in the guide sleeve (5), the lock nut (17) has a bar-shaped groove (21), the pin shaft (16) passes through the valve stem (9) and is embedded in the bar-shaped groove (21), Prevent the valve clack (3) from rotating and affect the sealing performance of the valve.

[0021] The upper end of the guide sleeve (5) is embedded in the groove of the valve body (1), and the positioning plate (14) is placed above the guide sleeve (5), which is compressed by the spring cover (11). When the steam safety valve is opened to the full stroke, the upper end surface of the disc sleeve (4) pushes against the positioning plate (14) to limit the opening height, and the positioning sleeve (15) is set on the positioning plate (14) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com