Semi-automatic test tube washer

A semi-automatic and scrubber technology, applied in the field of laboratory equipment, can solve problems such as waste of water resources, broken test tubes, cumbersome operation process, etc., to achieve the effect of reducing the operation process, ensuring universality, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

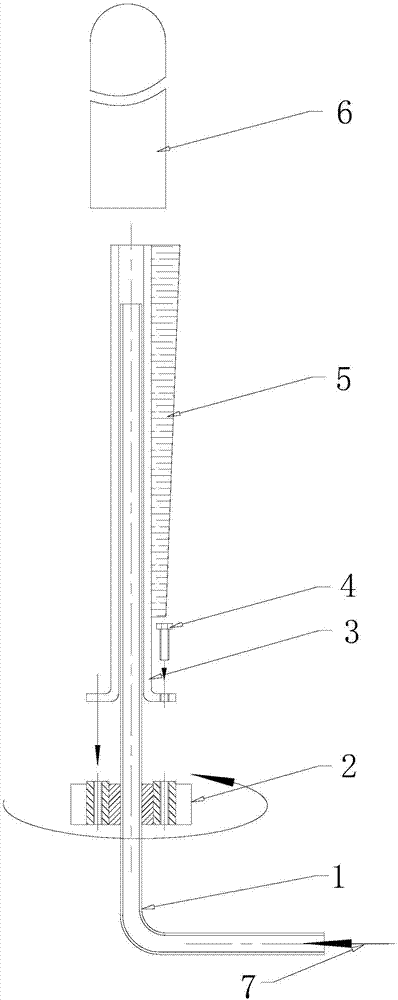

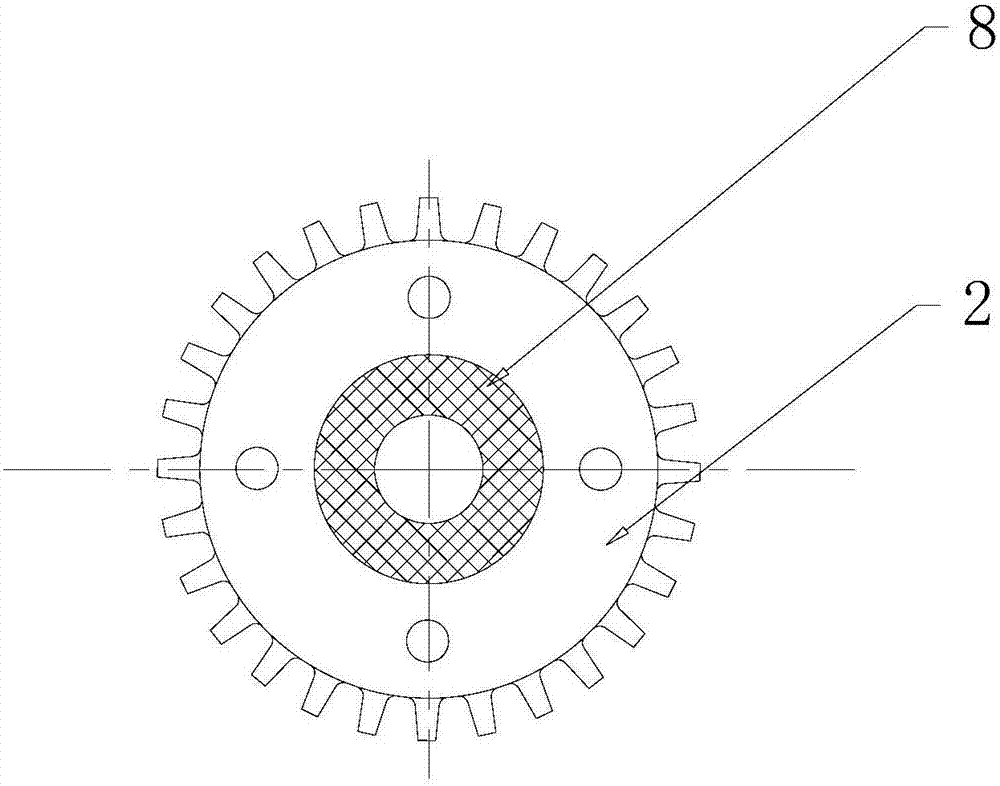

[0023] refer to figure 1 and figure 2 , is a kind of semi-automatic test tube scrubber, comprises liquid conveying pipe 1, gear transmission system, brush rod 3, and the water pump that conveys liquid for liquid conveying pipe 1; The tray gear 2 is driven by a motor and rotates around the bearing 8; the brush bar 3 is hollow to form a channel, the lower end of the brush bar 3 is detachably fixed on the tray gear 2, and the outer periphery of the brush bar 3 is provided with a number of bristles 5; The liquid port passes through the bearing 8 and is inserted into the channel, and the infusion port 7 of the liquid delivery pipe 1 is connected with the water pump. As shown in the figure, the vertical arrow indicates the installation direction of the bolt 4, the horizontal rotation arrow indicates the rotation direction of the tray gear 2, and the arrow at the liquid delivery pipe 1 indicates the liquid flow direction.

[0024] The setting of the tray gear 2 drives the brush ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com