Closed type heat-exchange hot water system utilizing intermittently supplied waste heat

A hot water system and closed-circuit technology, applied in the field of waste heat utilization hot water engineering, can solve the problems of energy waste, uneconomical, high energy consumption of standby energy, save investment and operating costs, better use comfort, and economical operation. energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

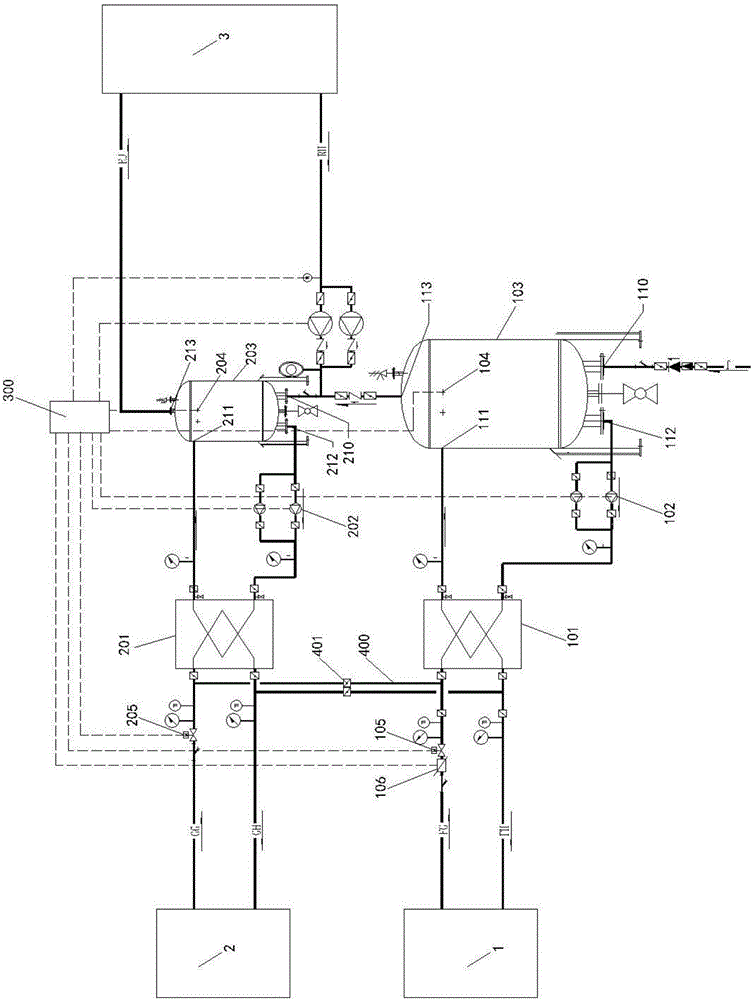

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] Waste heat supply phase:

[0022] Cold water enters the hot water storage tank 103 from the water supply port 110, and the temperature sensor 104 is used to judge the water temperature of the hot water storage tank 103. When the water temperature does not meet the preset condition 1, the solenoid valve 105 is opened, and the waste heat energy 1 passes through the heat exchanger. 101, start the internal circulation pump 102 between the hot water storage tank 103 and the heat exchanger, cold water enters the heat exchanger 101 from the inner circulation outlet 112 of the hot water storage tank, exchanges heat with the waste heat energy 1, and flows from the hot water storage tank The circulating water inlet 111 enters to heat the water in the hot water storage tank 103 . When the water temperature satisfies preset condition 1, the No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com