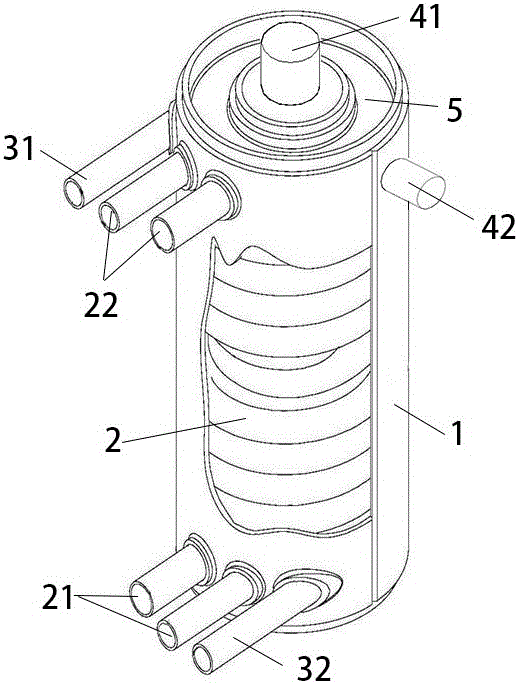

Spray tank type heat exchanger and using method thereof

A technology of heat exchangers and spray tanks, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve problems such as difficult operation, complicated connection structure, and unsatisfactory heat exchange efficiency, and improve efficiency , Improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] Embodiment 2, the gaseous refrigerant inlet 31 on the spray tank heat exchanger is omitted, and only the liquid refrigerant inlet 41 is reserved, and the liquid refrigerant inlet 41 is used for both gaseous refrigerant and liquid refrigerant. The refrigerant enters, and the gaseous refrigerant inlet 31 and the liquid refrigerant inlet 41 are combined into one, so that the structure of the heat exchanger is simpler and the operation is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com