Paper tube drying chamber for paper tube production

A technology of drying box and paper tube, which is used in drying solid materials, dry goods handling, drying room/container, etc., can solve the problems of high labor intensity, affecting the quality of paper tube, deformation of paper tube, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

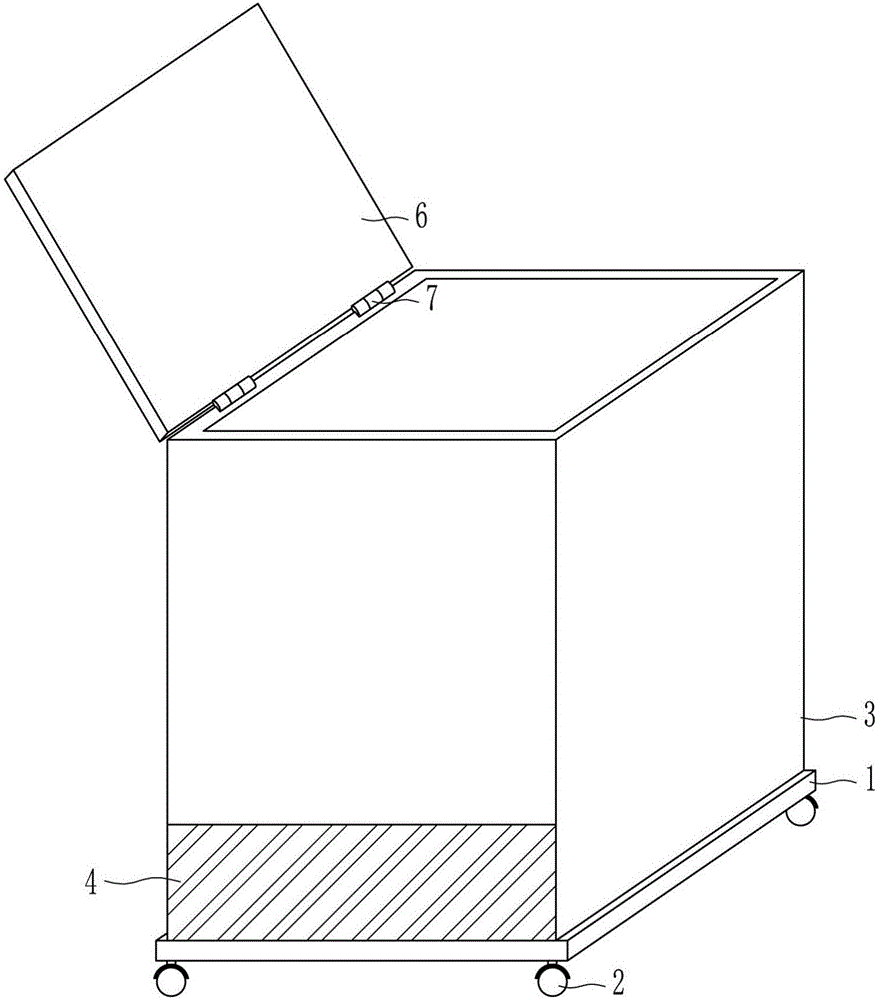

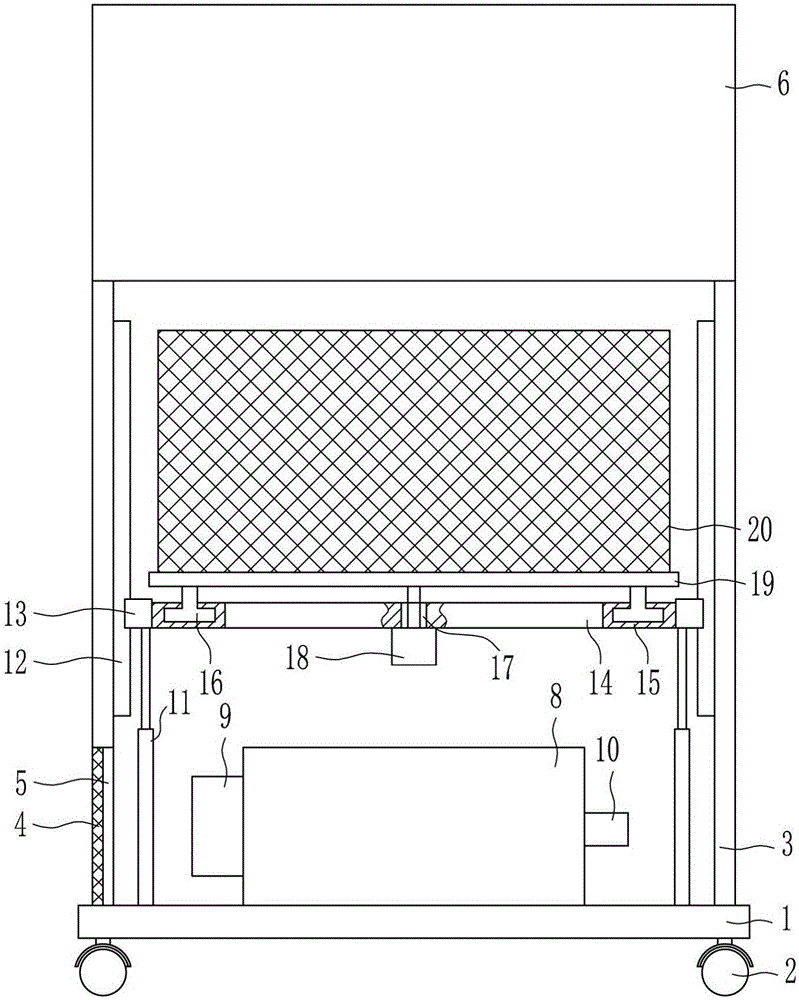

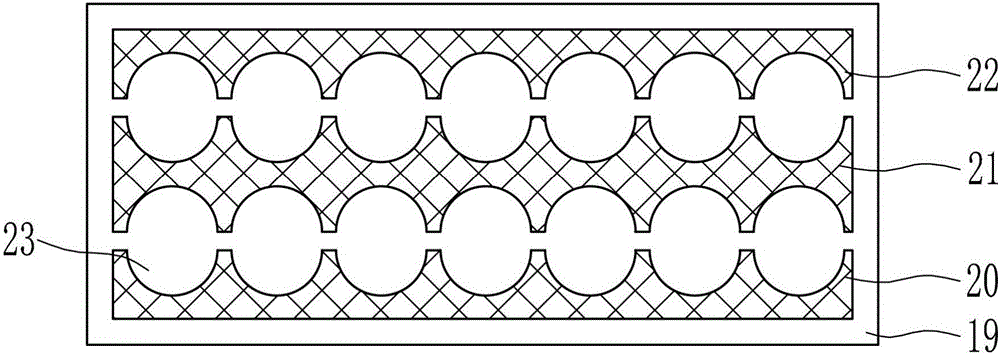

[0038] A paper tube drying box for paper tube production, such as Figure 1-10 As shown, it includes a base 1, wheels 2, a box 3, a protective mesh plate 4, a cover 6, a hinge 7, a hot air blower 8, a cylinder 11, a first slide rail 12, a first slider 13, a fixed plate 14, The annular slide rail 15, the second slider 16, the servo motor 18, the connecting plate 19, the first mesh plate 20, the second mesh plate 21 and the third mesh plate 22, the four corners of the bottom of the base 1 are equipped with wheels 2, A box body 3 is welded on the top of the base 1, the box body 3 is open, the left side of the box body 3 is provided with a hinge 7, the left side of the box body 3 is provided with a cover 6, and the cover 6 is connected with the box body 3 through the hinge 7 , the lower part of the front side of the box body 3 is provided with an air inlet 5, the box body 3 at the air inlet 5 is provided with a protective mesh plate 4, and the inner bottom of the box body 3 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com