Visible longitudinal-flow all-pin-fin tube lubricating oil cooler

A cooler and lubricating oil technology, which is applied to fixed tubular conduit components, heat exchanger types, heat exchanger shells, etc., can solve the problems of lubricating oil viscosity reduction, low heat exchange efficiency, and bulky equipment, and achieve Reduce flow resistance and improve heat transfer efficiency, flexible space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

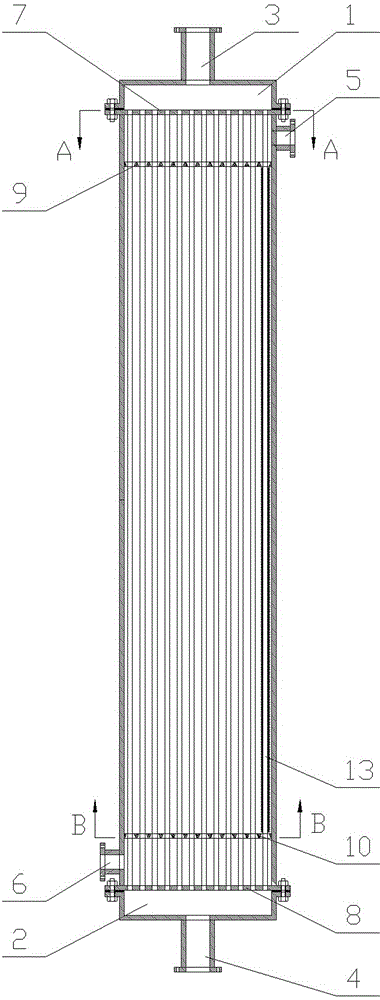

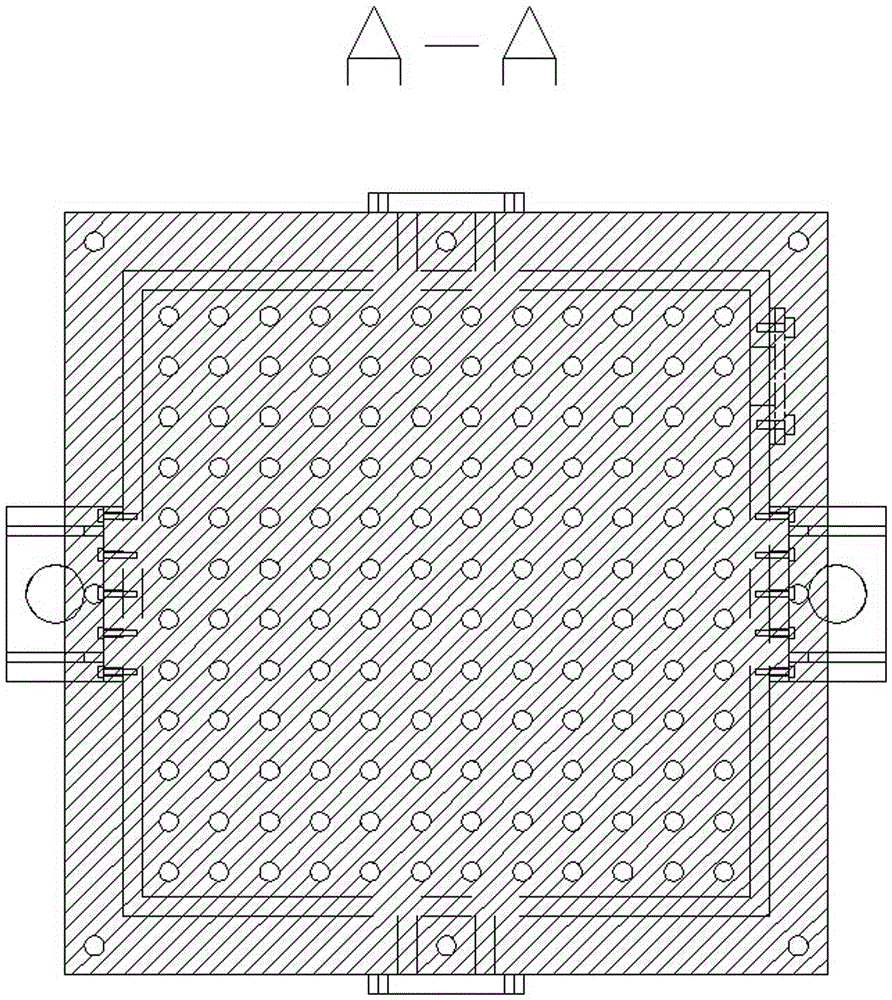

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

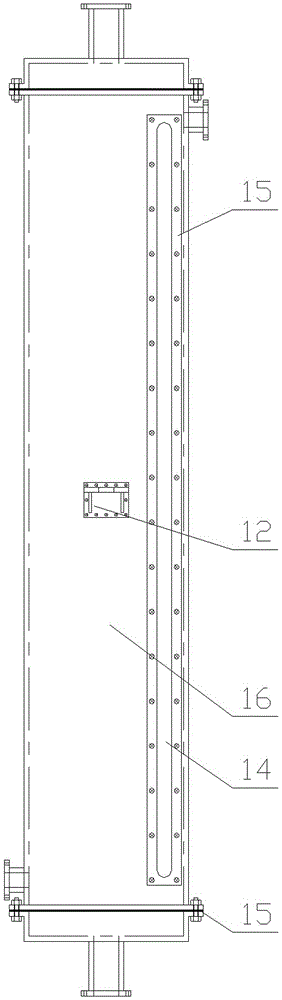

[0022] like figure 1 As shown, the longitudinal flow full pin-fin tube visible oil cooler of the present invention includes an integral pin-fin tube bundle 13, an upper oil spoiler 9, a lower oil spoiler 10, an upper tube plate 7, and a lower tube plate 8 , upper head 1, lower head 2, shell 16, wherein:

[0023] The upper tube plate 7 and the lower tube plate 8 are respectively fixed on the upper and lower end surfaces of the shell 16, the upper tube plate 7 is fixed with the upper head 1, and the lower tube plate 8 is fixed with the lower head 2, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com