A Roof Controlled Blasting Method for Ore Body Recovery with Soft Broken Roof

A technology for controlling blasting and roofing, applied in blasting, ground mining, earthwork drilling, etc., can solve the problems of failure to meet the strength requirements of the supporting roof, blasting and cracking of the protective roof, low compressive strength, etc., so as to reduce ore leanness. The effect of reducing the over-excavation rate, preventing the collapse of the roof, and reducing the amount of over and under excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

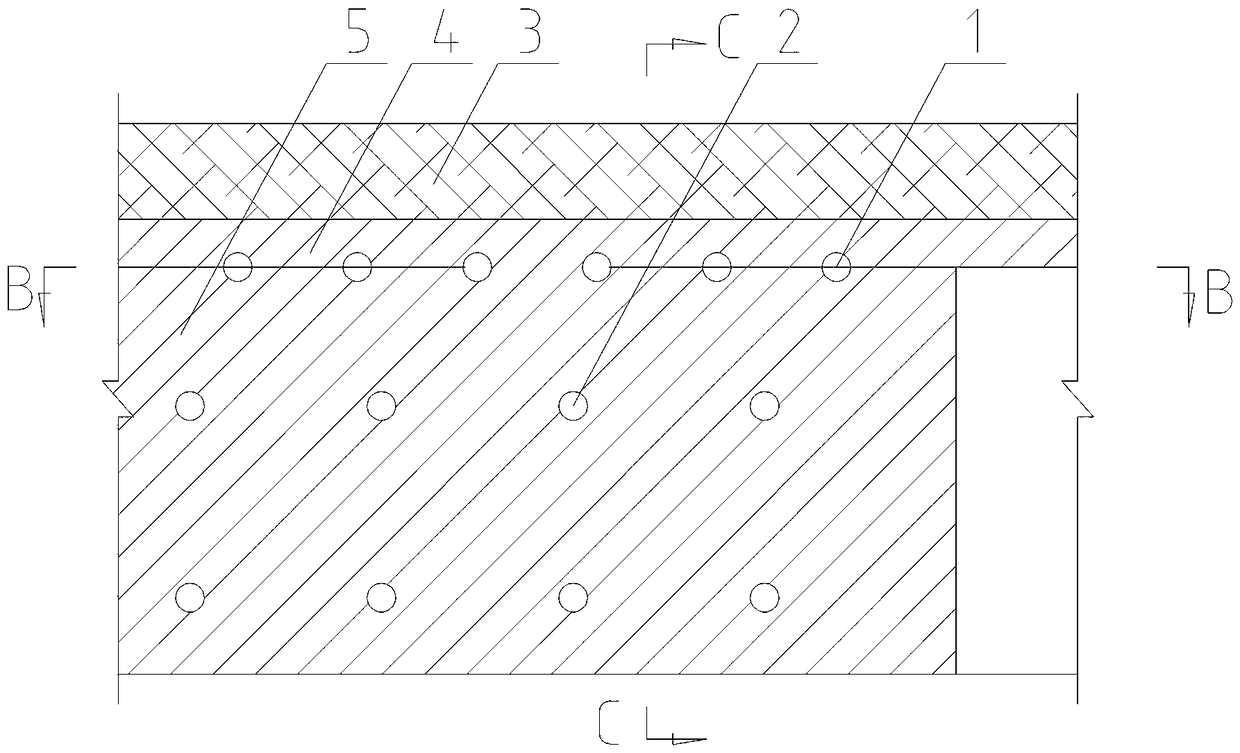

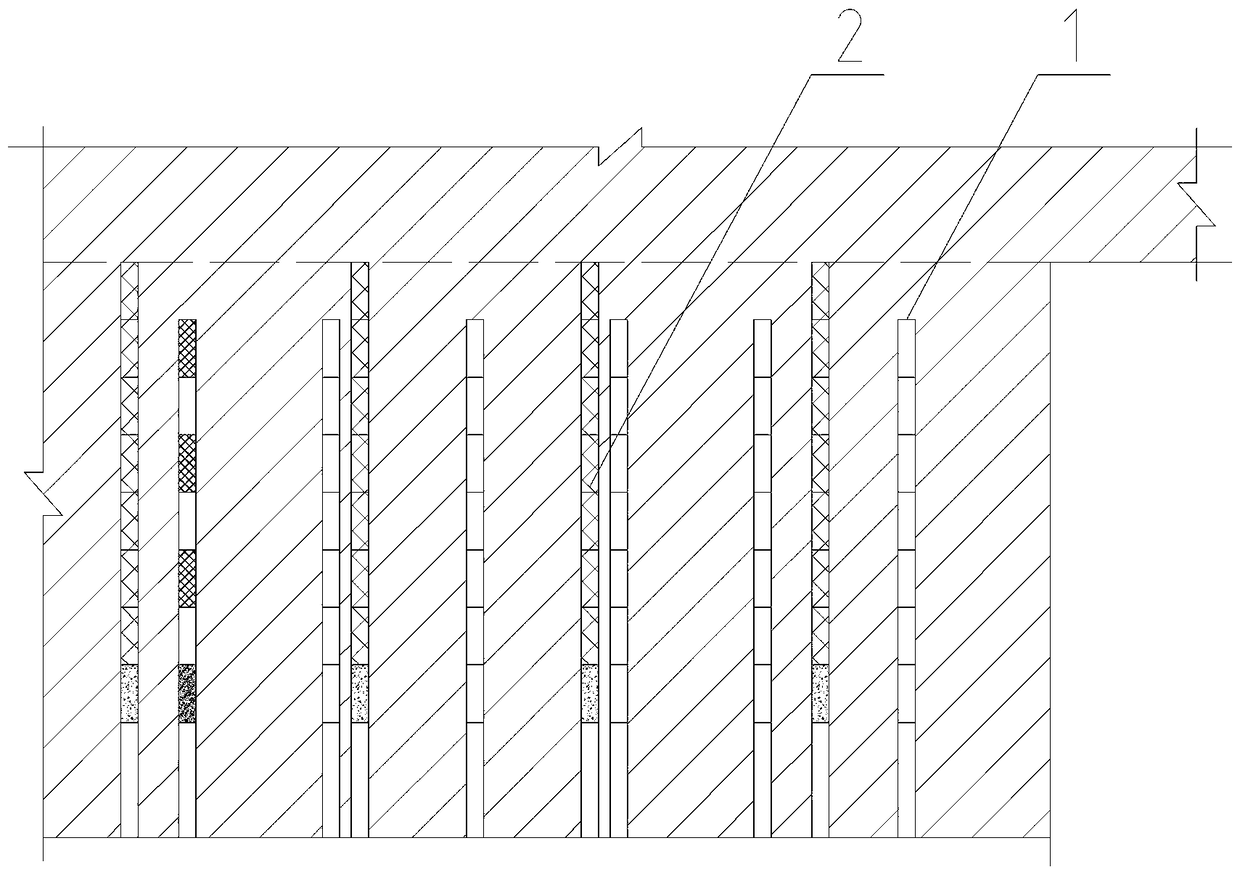

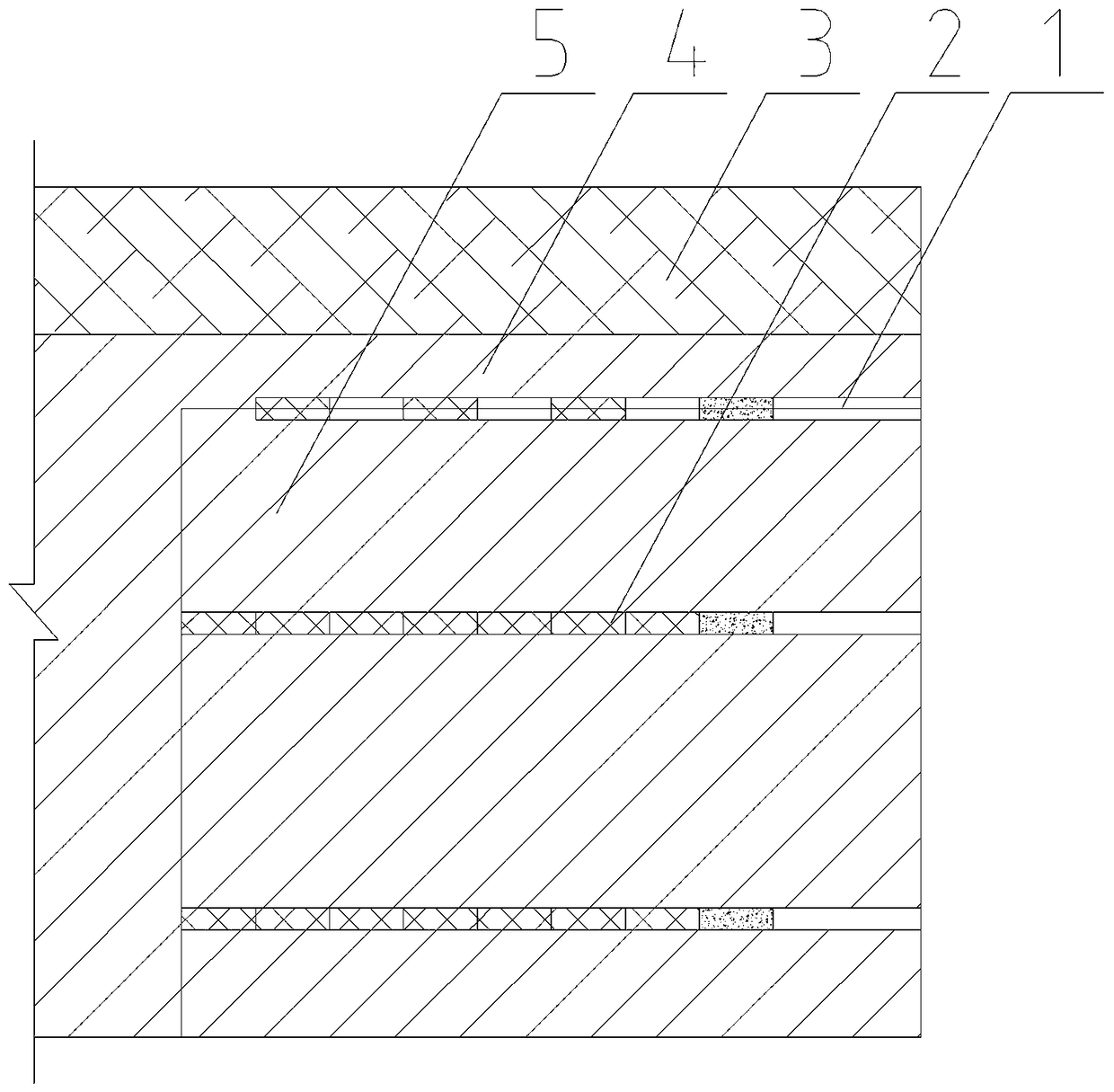

[0023] Taking a bauxite mine in Henan as an example, the ore body is distributed in a nearly long strip from east to west, with a continuous length of 3000m from east to west, a width of 200m to 700m from north to south, an average width of 350m, and an ore body area of about 1.3km 2 . The ore seam is 0.43m-52.79m thick, with an average of 5.70m. It is mainly composed of bauxite ore, and there is a thin layer of clay ore on the top or in the middle. The compressive strength of the ore is 66.15MPa~132.87MPa, and the average internal friction angle is 40°42ˊ. The ore bed belongs to hard rock, and the stability of the ore bed is good.

[0024] The immediate roof of the ore seam is clay shale, which is thin, well-developed, soft and brittle, and exhibits the characteristics of water swelling and extremely low compressive strength. Underground mining needs support to prevent roof collapse.

[0025] The indirect roof is the Taiyuan Formation (C 3 t) The coarse-grained sandstone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com