Strain sensor multi-directional installation method

A technology of strain sensor and installation method, which is applied in the monitoring of internal temperature and multi-directional stress in the process of mass concrete construction, and the field of multi-directional installation of strain sensors, which can solve the problem of affecting structural safety and durability, unfavorable monitoring, and sensor damage Reading and other issues, to achieve the effect of not easy to change direction, high application and promotion value, and easy installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

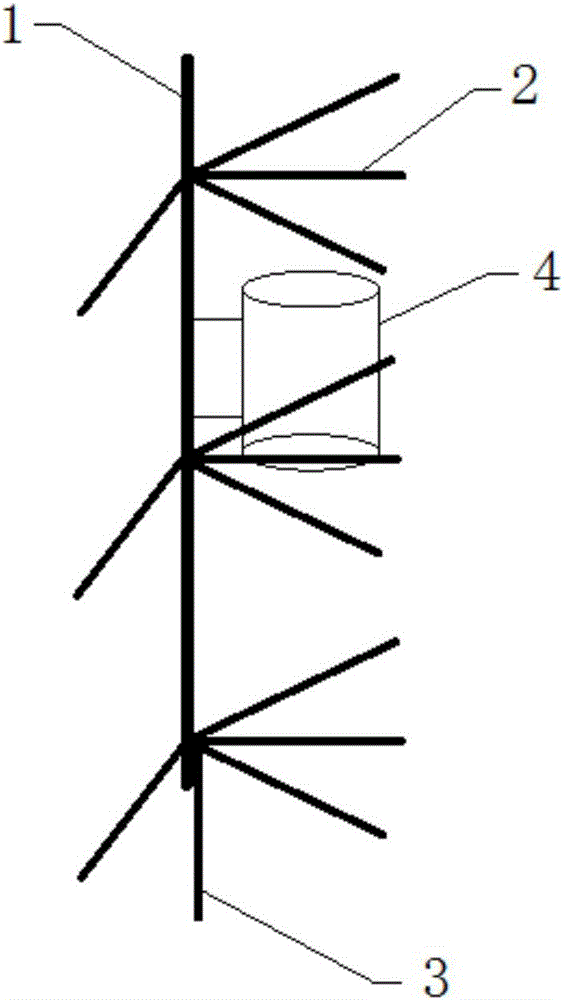

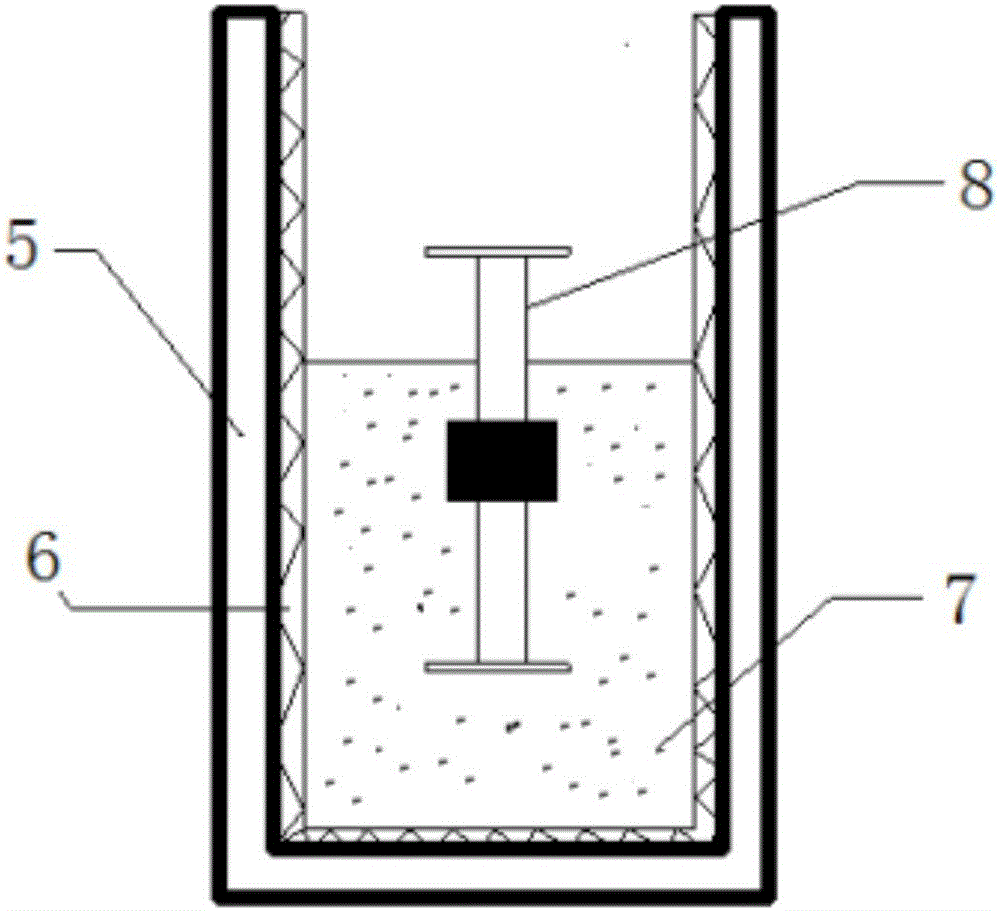

[0017] see figure 1 , according to the strain sensor multidirectional installation method of the present invention, carry out according to the following steps:

[0018] 1. After the analysis, place the support rod 1 in the determined analysis area, and ensure the verticality of the support rod 1, and there should be no tilting or bending of the support rod 1;

[0019] 2. According to the thickness of the poured concrete, determine the number of layers of direction sensor layout. Taking the third layer as an example, lay out the upper, middle and lower layers respectively, with appropriate spacing, and mark the corresponding positions;

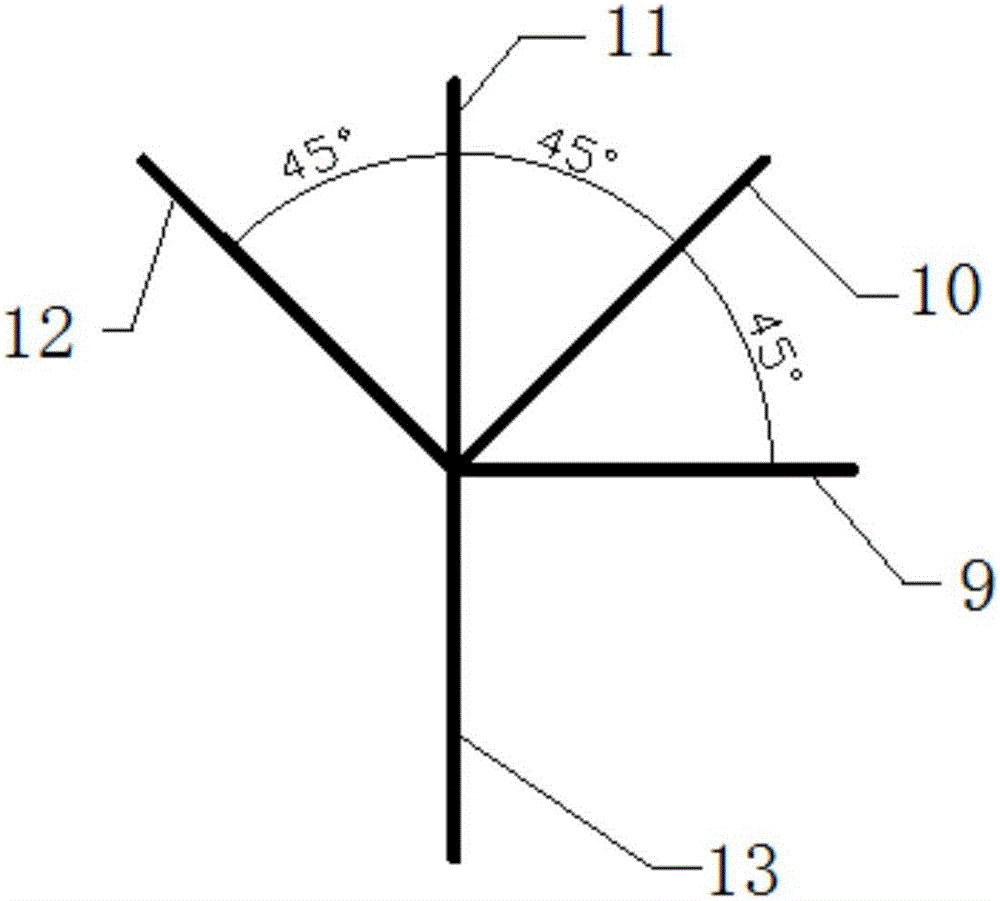

[0020] 3. In the predetermined orientation sensors on each layer, determine the layout direction of the orientation sensors, at least 3 orientations are used, and this embodiment adopts 5 orientations, which are 0° orientation sensor 9, 45° orientation sensor 10, and 90° orientation sensor 11 , 135 ° direction sensor 12 and vertical direction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap