Method and system for measuring chopping delay of switching Hall sensor

A Hall sensor and measurement method technology, applied in the field of sensors, can solve the problems of slowly changing magnetic field strength, single test method of switch-type Hall sensor, and difficult to directly test and obtain, and achieve simple measurement steps, low cost of hardware equipment, and difficult Directly Measured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

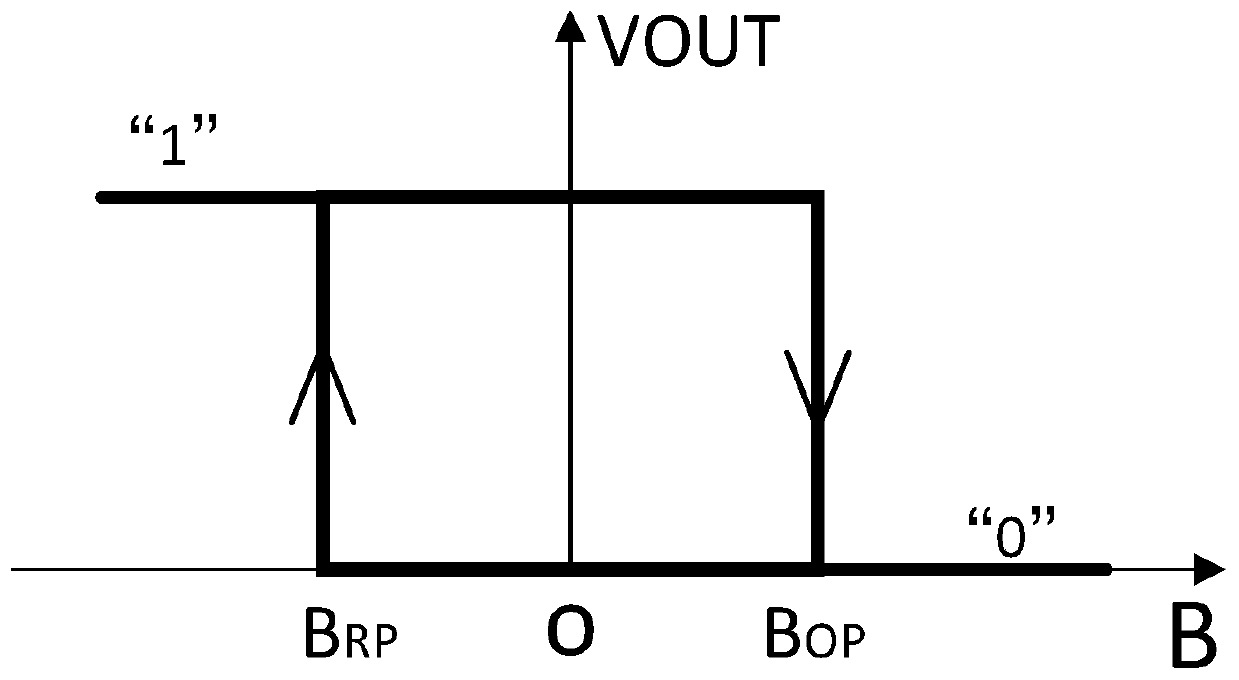

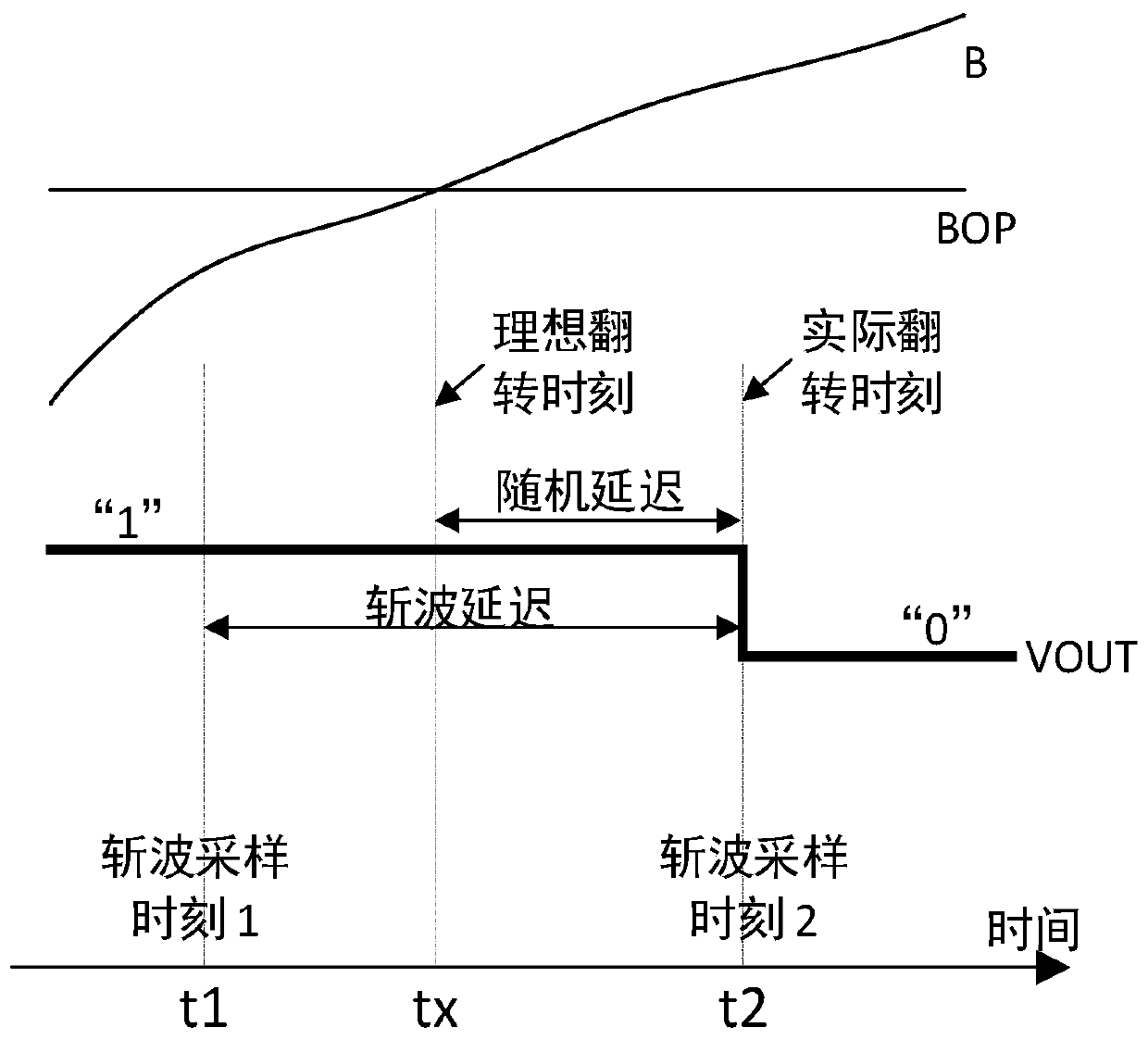

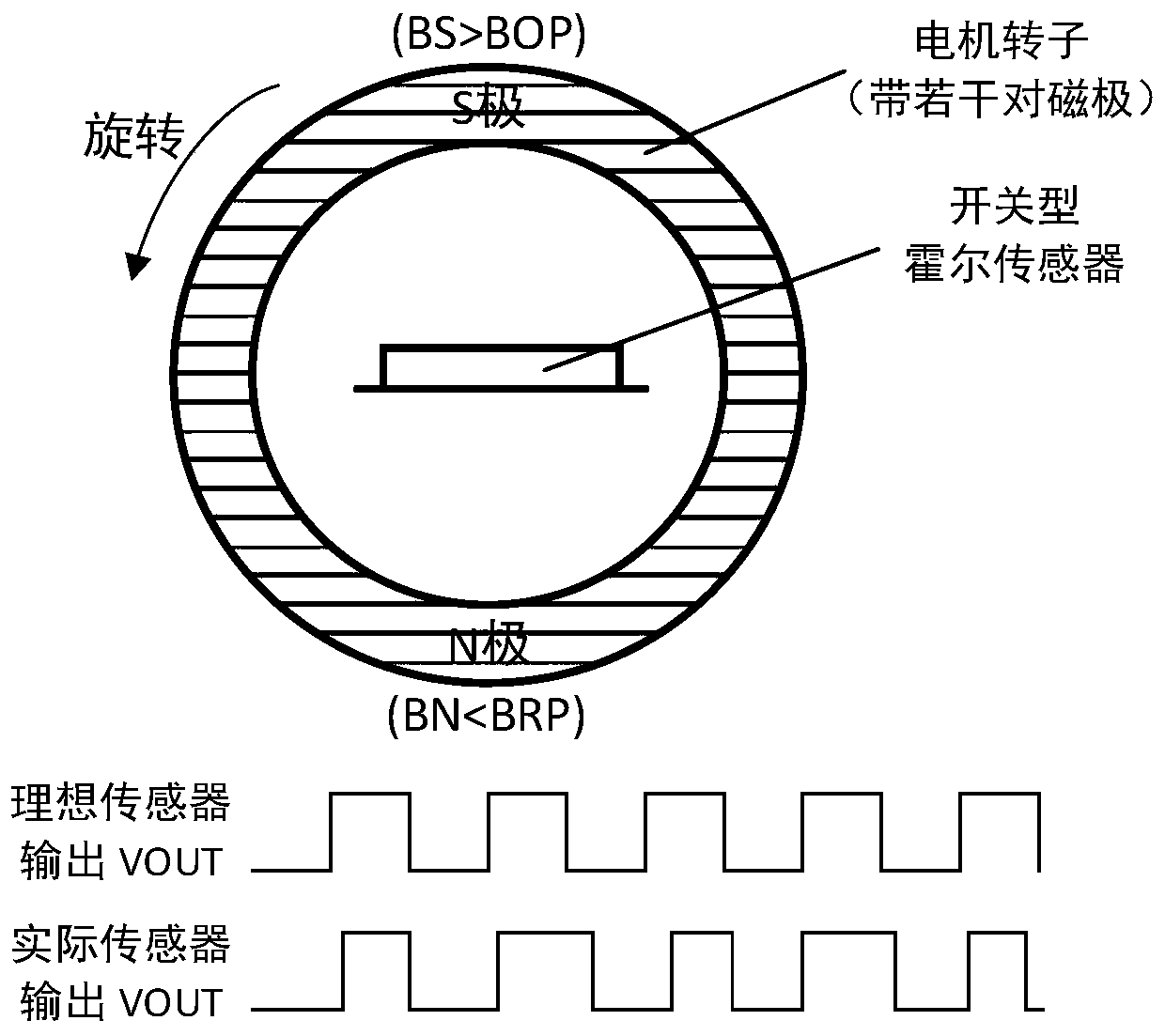

[0039] see figure 1 , the present invention discloses a method and system for measuring chopping delay of a switch-type Hall sensor. By placing a switch-type Hall sensor in a periodically changing magnetic field and observing the afterglow of the output signal of the sensor with an oscilloscope, the chopping delay can be indirectly measured. wave delay. Persistence display is a general display function of the oscilloscope, which can keep the waveform light spots on the oscilloscope display for a period of time.

[0040] test system such as Figure 4 As shown, it includes a device 100 capable of generating a periodically varying magnetic field, a DC power supply 200 , an oscilloscope 300 and a switch-type Hall sensor 400 to be tested. The switch-type Hall sensor includes at least 3 pins, which are power supply VCC, ground GND and output VOUT. Where VCC is connected to the positive output terminal of the DC power supply; GND is connected to the ground terminal of the DC power...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that in this embodiment, step 1 is the same as step 2 and the first embodiment, and step 3 can be replaced with a falling edge trigger to observe the afterglow of the next rising edge, namely:

[0048] Step 3: Set the oscilloscope to trigger mode, use Figure 5 The falling edge of the middle square wave is used as the trigger edge, and at the same time turn on the afterglow display function of the oscilloscope. waveform like Figure 7 shown. Among them, BX is the ambient magnetic field strength, which decreases monotonically in this experiment; BRP is the threshold value of the magnetic release point, which is a constant value; BX is greater than BRP at the initial time, and will be less than BOP at the final time; the sensor output waveform displayed on the oscilloscope is VOUT. In the VOUT waveform, R is the falling edge used for triggering. After a period of time, VOUT will have a rising edge. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com