Aeroengine low pressure turbine shaft disc fastening force detection method and device based on linear laser displacement sensor set

A technology of displacement sensor and low-pressure turbine shaft, which can be used to measure the direction of torque/torsional force during tightening, which can solve the problems of low test efficiency, achieve fast detection speed, solve detection difficulties, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

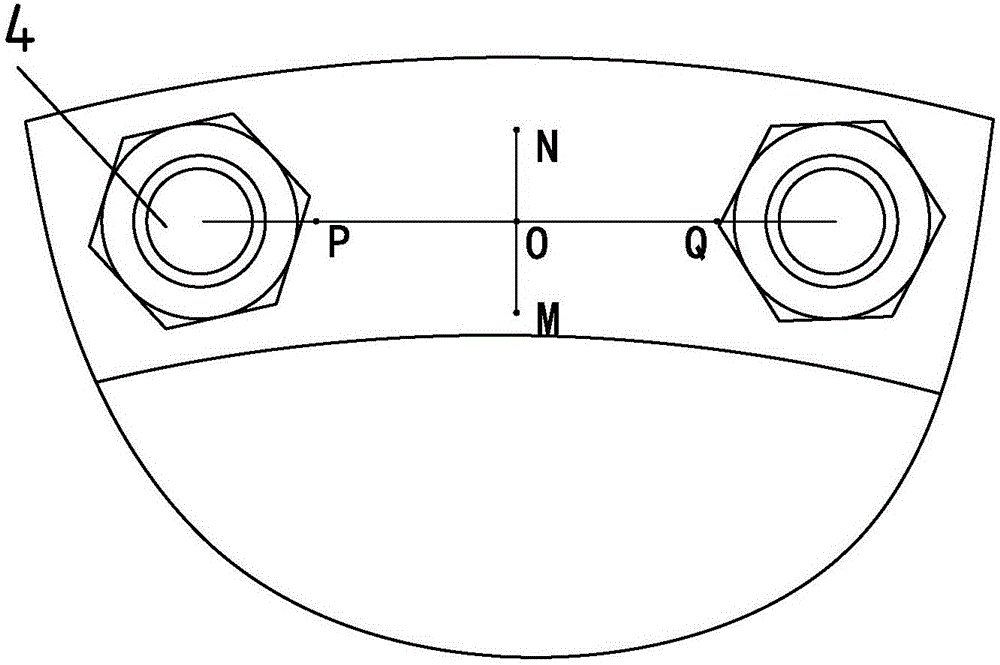

[0066] A method for detecting fastening force of an aeroengine low-pressure turbine shaft disk based on a line laser displacement sensor group, the line laser displacement sensor group includes a line laser displacement sensor Ⅰ and a line laser displacement sensor Ⅱ, a line laser displacement sensor Ⅰ and a line laser displacement sensor Ⅱ Arranged in a straight line along the diameter of the disk surface of the low-pressure turbine shaft disk and the distance to the center of the disk surface of the low-pressure turbine shaft disk is S, and S is equal to the midpoint of the line connecting two adjacent bolts on the low-pressure turbine shaft disk The distance from O to the center of the disk surface of the low-pressure turbine shaft disk, the installation planes of the line laser displacement sensor I and the line laser displacement sensor II are perpendicular to each other,

[0067] The detection method has the following steps:

[0068] S1. Obtain the relationship between t...

Embodiment 2

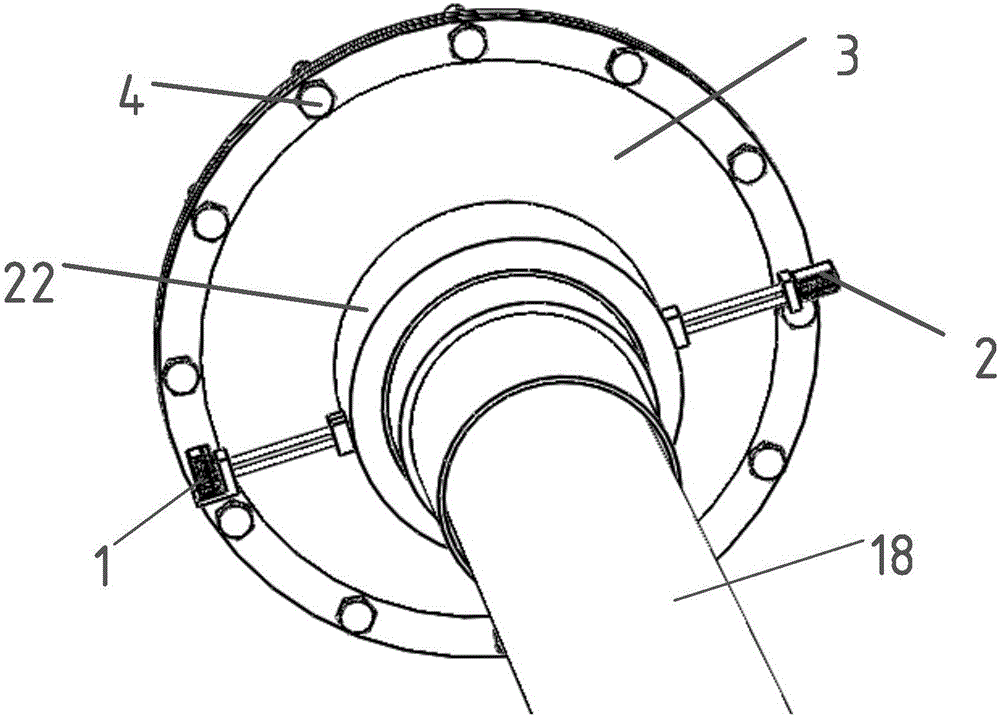

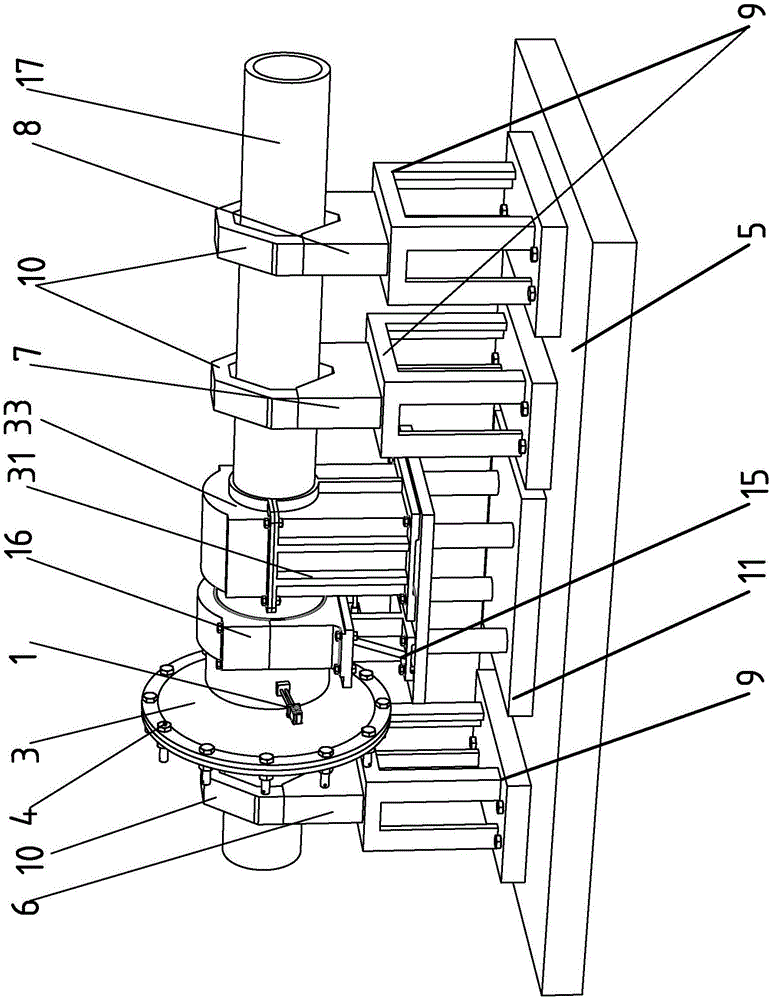

[0098] like Figure 1-5 As shown, an aeroengine low-pressure turbine shaft plate fastening force detection device based on a line laser displacement sensor group, the line laser displacement sensor group includes a line laser displacement sensor I1 and a line laser displacement sensor II2, a line laser displacement sensor I1 and a line laser displacement sensor The displacement sensor II2 is arranged in a straight line along the diameter of the disk surface of the low-pressure turbine shaft disk 3 and the distance from the center of the disk surface of the low-pressure turbine shaft disk 3 is S, the installation plane of the line laser displacement sensor I1 and the line laser displacement sensor II2 are perpendicular to each other, wherein, S is equal to the distance from the midpoint O of the line connecting two adjacent bolts 4 on the low-pressure turbine shaft disk 3 to the center of the low-pressure turbine shaft disk 3,

[0099] The test device includes a base 5 and a V-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com