Steady temperature pressure combined probe for measuring transonic speed two-dimensional flow field

A two-dimensional flow field, temperature and pressure technology, applied in the field of pressure testing and flow field temperature, can solve the problems of large measurement error, high test cost, long measurement time, etc., and achieve the effect of comprehensive measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

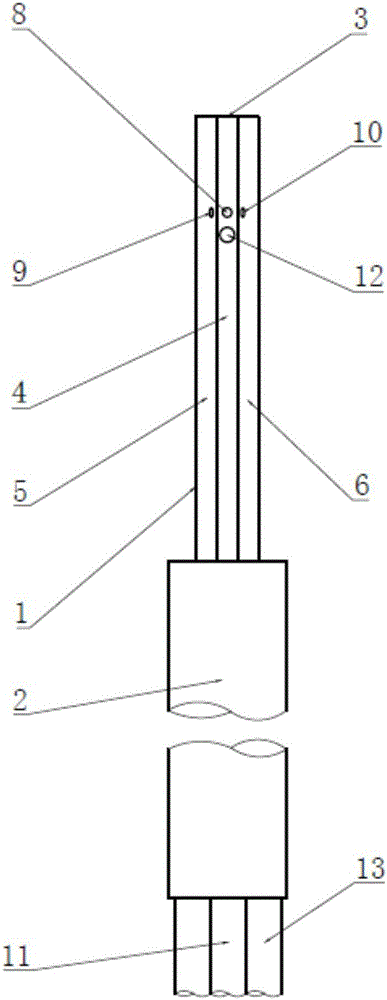

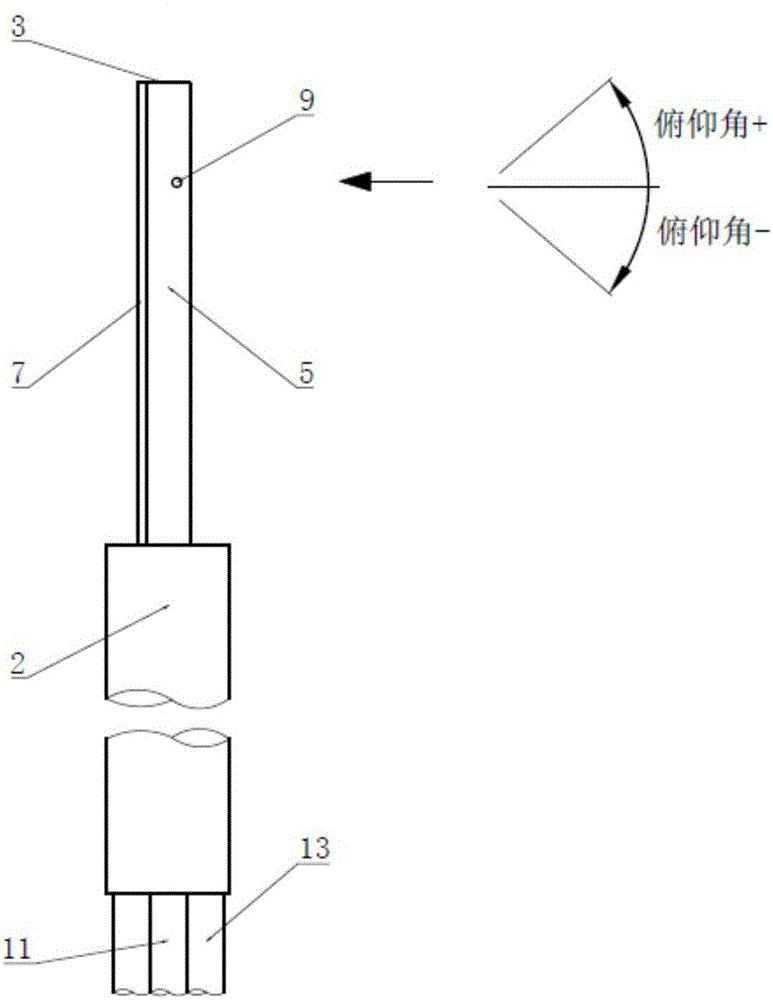

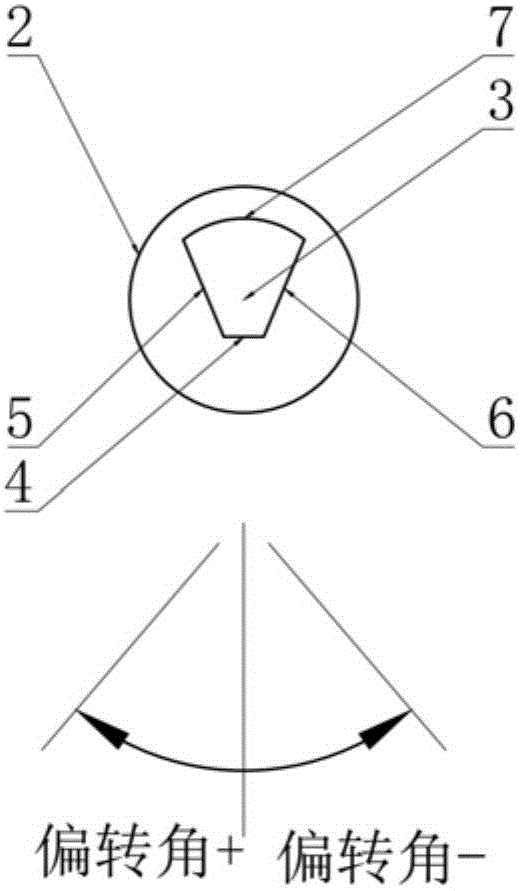

[0021] Such as figure 1 As shown, in this embodiment, a steady-state temperature-pressure combination probe for measuring a transonic two-dimensional flow field is introduced, including a probe head (1), a support rod (2), and the probe head (1) is The four-prism structure has a circumscribed circle diameter of 6 millimeters, the probe head (1) is 30 millimeters high, and the top surface (3) of the probe head (1) is perpendicular to the rotation axis of the probe support rod (2). During probe measurement, the windward side of the probe head (1) includes the frontal plane (4), the left plane (5) and the right plane (6), and the leeward side is a cylindrical arc surface (7); There are one pressure-sensing hole in the front plane (4), left plane (5) and right plane (6) of the part (1), which are middle hole (8), left hole (9) and right hole ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com