Integrated mounting frame for aero-engine test run

An aero-engine and mounting frame technology, which is used in engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of large size of the bench, time-consuming and laborious installation, and lack of versatility of the bench, so as to achieve convenient transfer. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

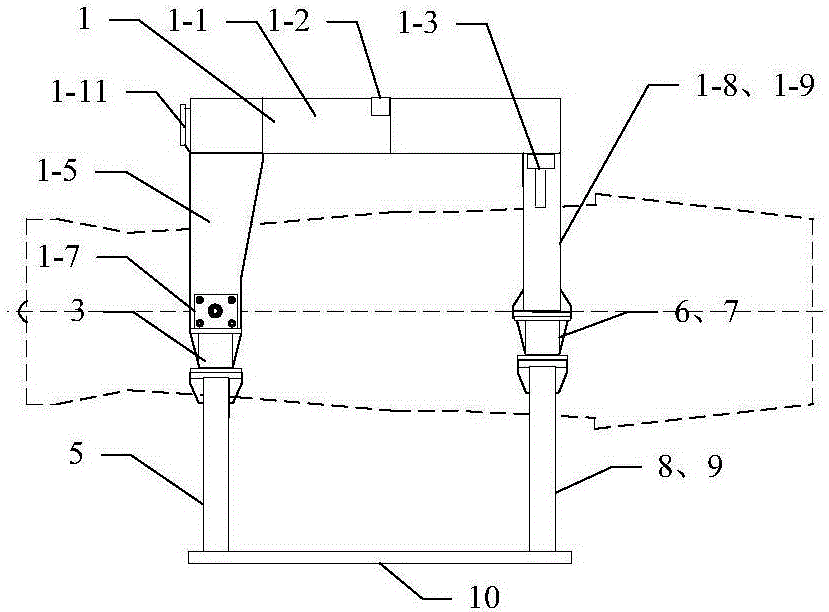

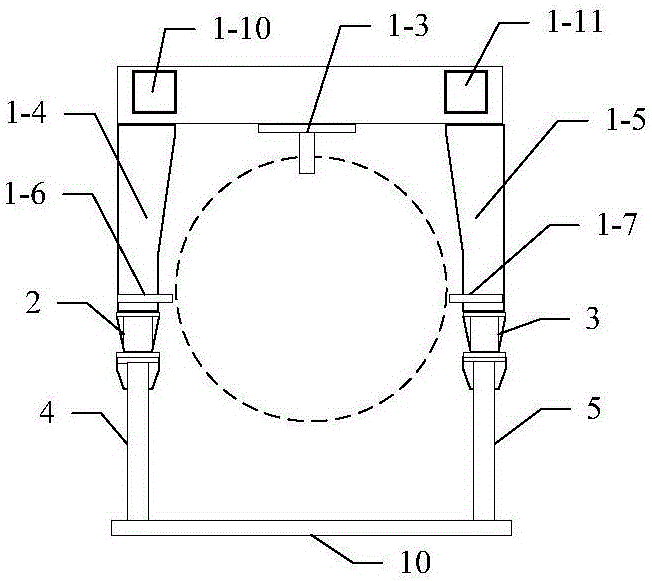

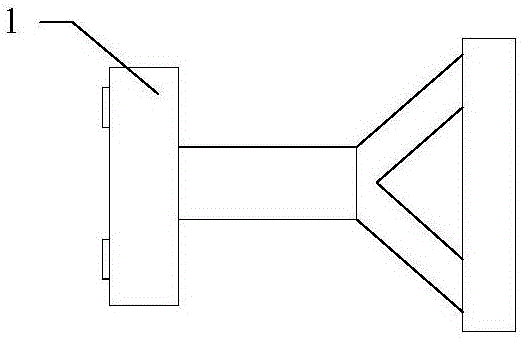

[0023] The integrated mounting frame is a pre-installed frame for the engine ground test. The main technical features of the integrated mounting frame include: main fulcrum, auxiliary fulcrum, driving interface, suspension interface, supporting platform interface, transfer platform interface, etc. During installation, hang the suspension frame above the engine to be tested by driving, and complete the installation of the main and auxiliary fulcrums; adjust the suspension frame and the engine as a whole to the support seat of the bottom plate, and wait until the installation of the engine accessories and test pipelines is completed; you can Transfer the integrated mounting frame and the engine to the test bench for test installation, select the installation plane and interface of the integrated mounting frame according to the test bench structure (suspension or support type), and remove the redundant support seat and adapter seat during the installation process .

[0024] An in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com