Passive pile model test system

A model test and passive pile technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve problems such as low precision, uneven loading of lateral loading devices, and inability to simulate load forms, etc. To achieve the effect of improving project safety reserve and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

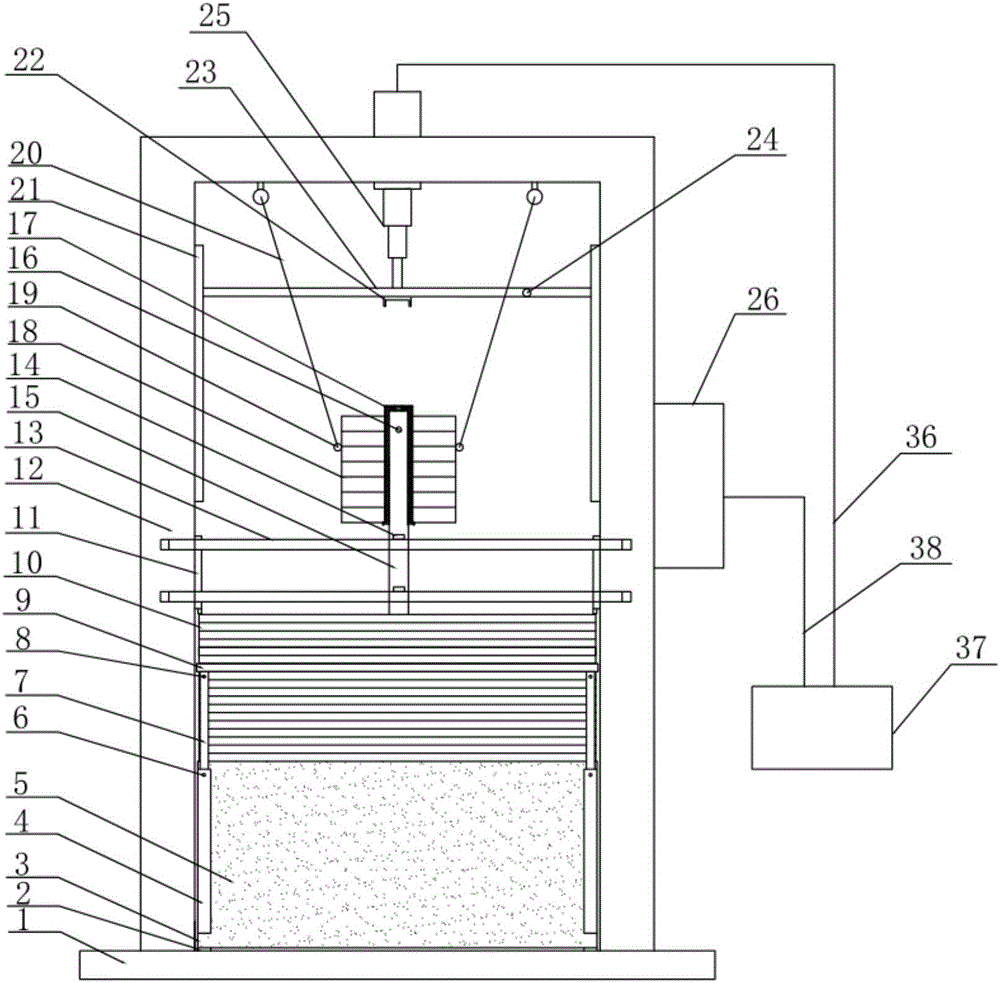

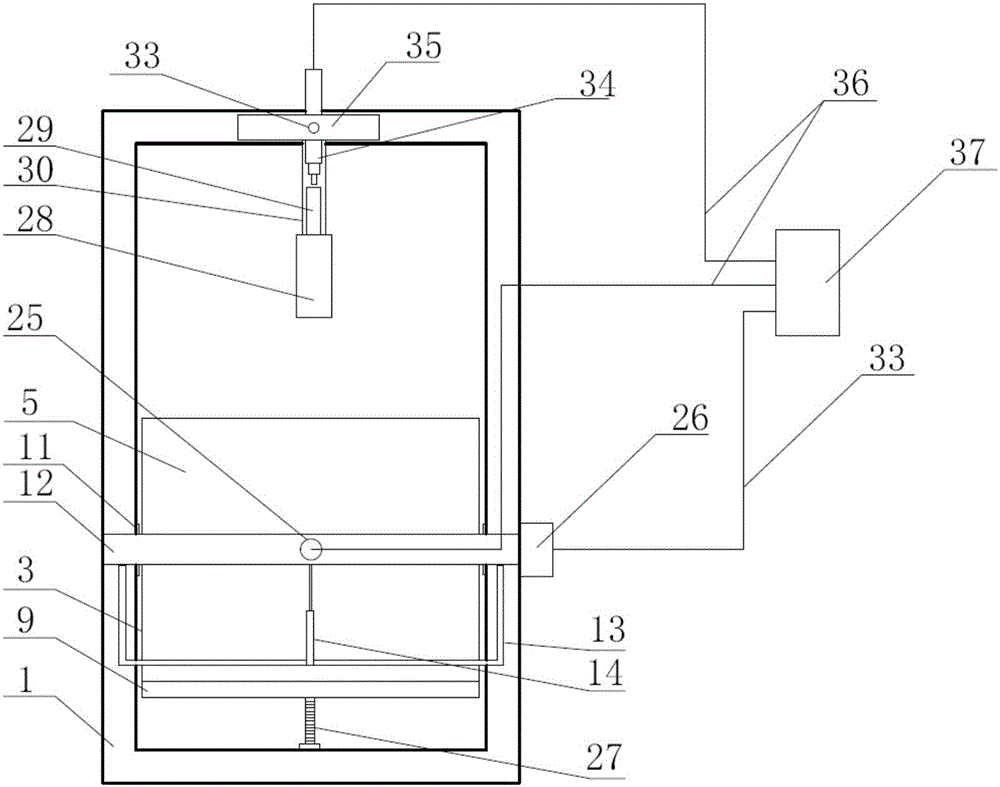

[0028] The structure of the passive pile model test system of the present invention will be described below in conjunction with the accompanying drawings.

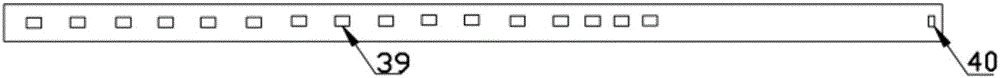

[0029] Such as figure 1 , 2 , shown, the structure of the passive pile model test system of the present invention is that the system includes a model box, a moving slider 10, a pile pressing device, a vertical loading system, a lateral loading system, a data acquisition system and a model pile 15. Sand soil 5 is housed in the model groove 3 that is provided with in the described model box, utilize vertical hydraulic jack 25 to press model pile 15 in the sand soil 5 in the model groove 3, install vertical loading system at model pile 15 pile tops , use the lateral hydraulic jack 34 to push the moving slider 10, and then use the data acquisition system to record the test parameters of the pile body to simulate the passive pile model test.

[0030] The model box includes a bottom support 1, a screw rod member 27, a fixed sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com