Automatic determination method of friction mark direction angle of friction spot image of four-ball friction test

A measurement method and a technology of direction angle, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as inaccurate measurement accuracy and perception errors of experimenters, and achieve the goal of overcoming measurement accuracy and increasing processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] The present invention proposes a method for automatically detecting the direction angle of a steel ball wear scar image, comprising the following steps:

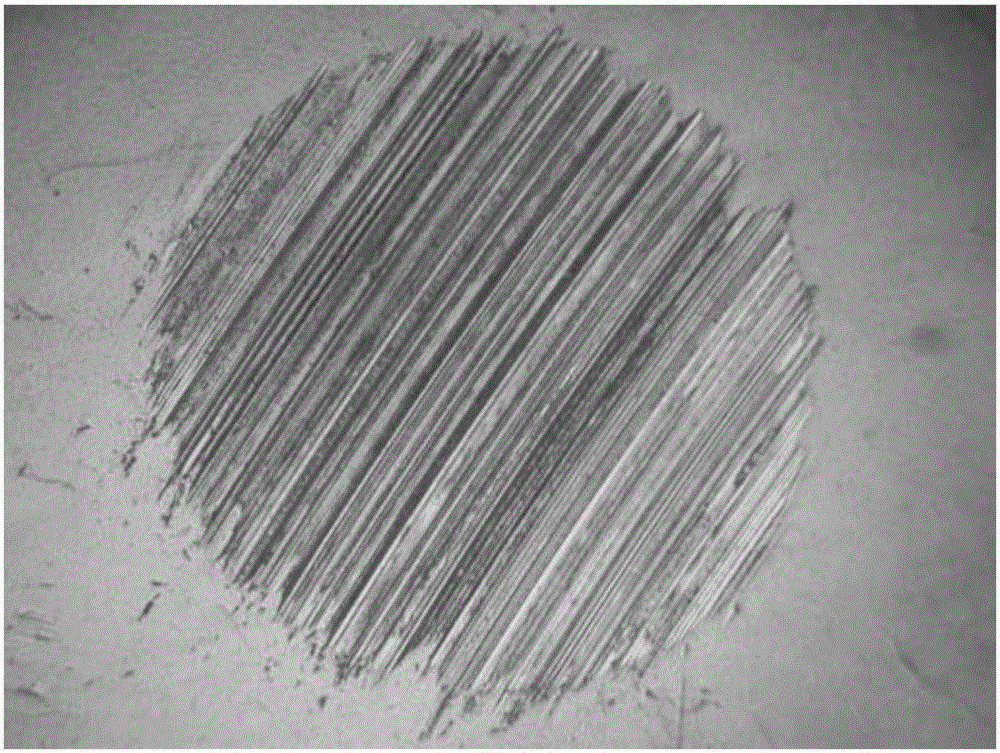

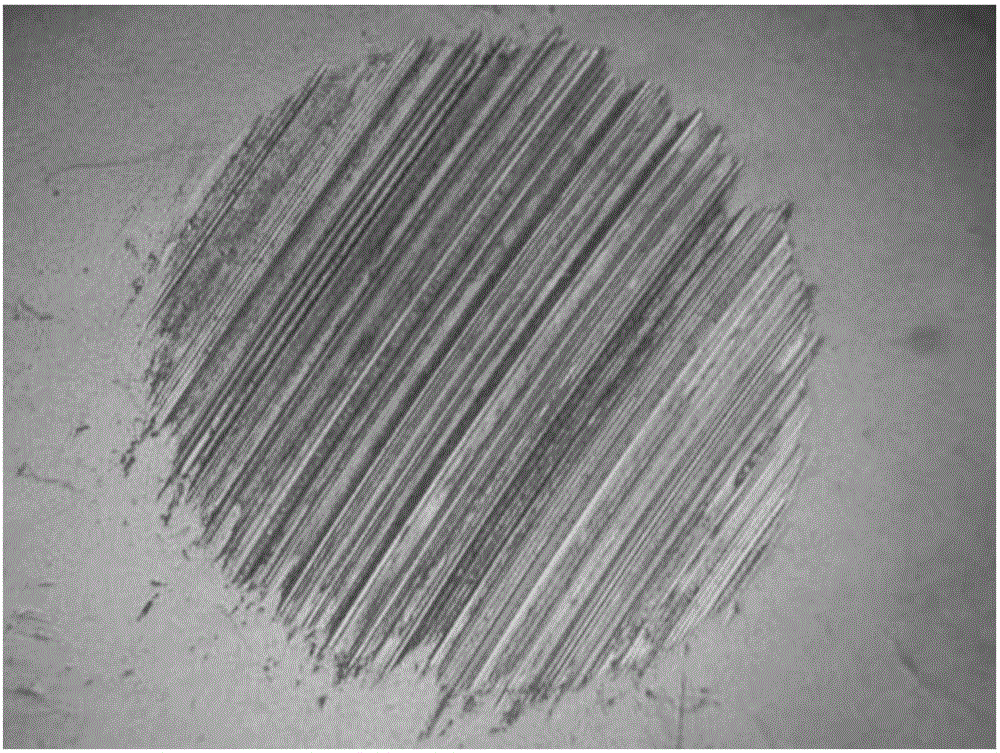

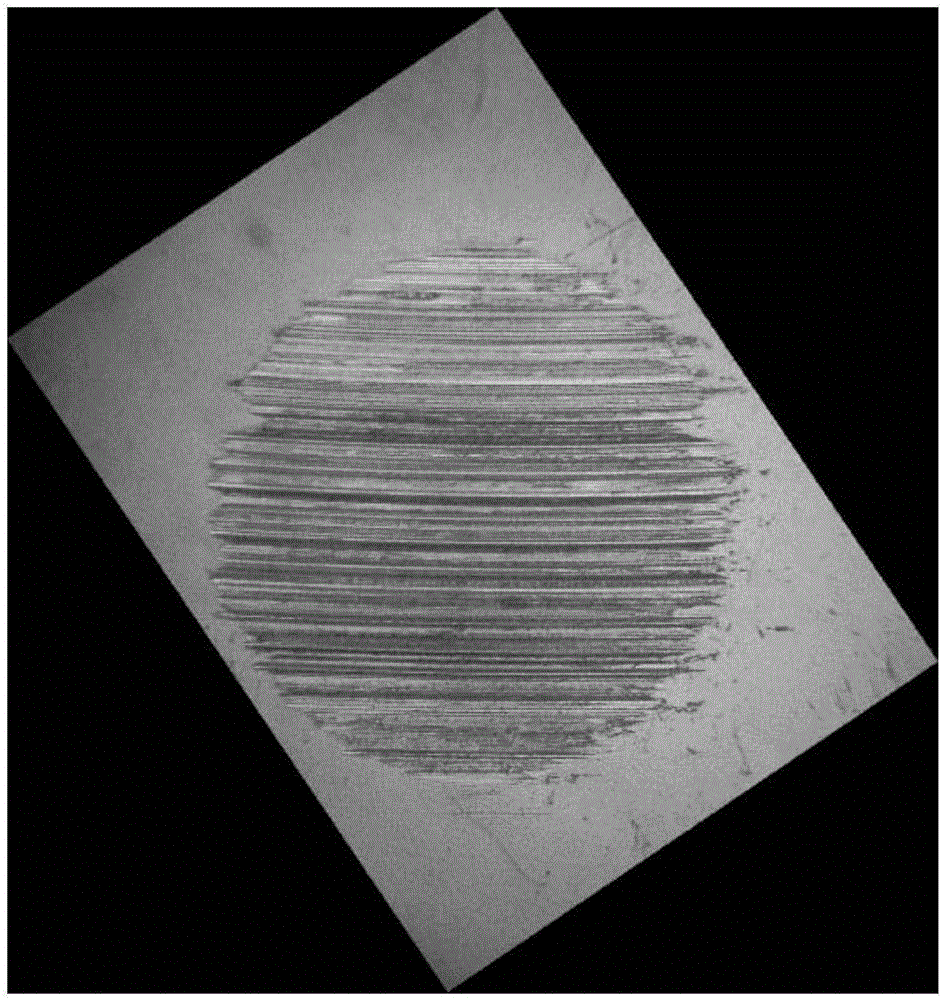

[0039] Step S1: collecting wear scar images of the test steel balls through a scanning electron microscope. Specifically: after the four-ball friction test, the three bottom steel balls used in the test were taken out and placed in the scanning electron microscope, and the parameters such as the illumination and magnification of the scanning mirror were adjusted at the same time to clearly collect the wear spot image. The collected wear scar image is denoted by F, and the size of the wear scar image F is M×N. The wear spot image F collected in the embodiment is as figure 1 As shown, its size is 768×1024, that is, M=768, N=1024, use (x, y) to represent the coordinates of any pixel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com