Plastic part defect detection method based on multiple threshold intervals

A technology for detection of plastic parts and defects, applied in the directions of optical testing defects/defects, measuring devices, analyzing materials, etc., can solve the problems of waste of resources, high consumption of human resources, low detection efficiency, etc., so as to reduce false detection or missed detection. , Improve the detection speed and accuracy, and improve the effect of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

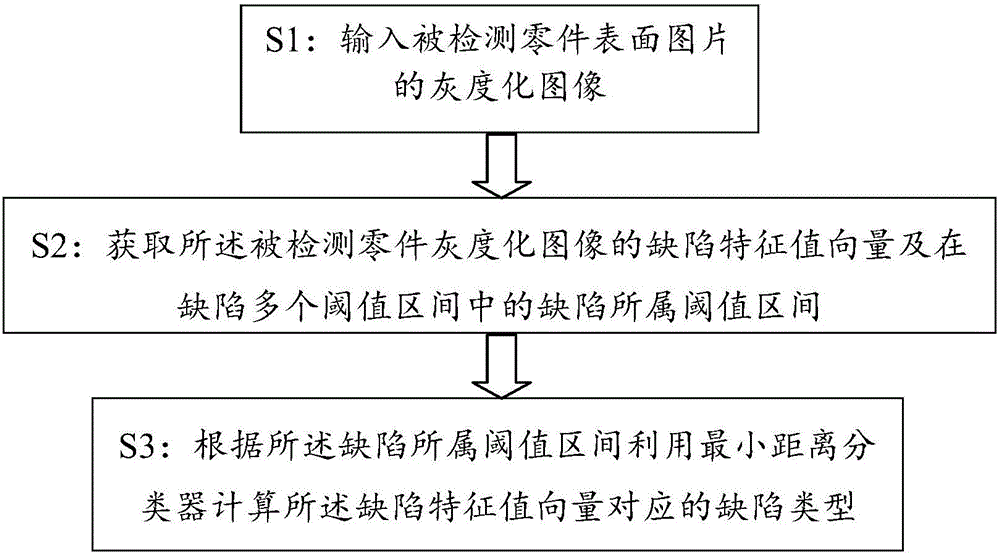

[0018] The present invention provides a plastic part defect detection method based on multiple threshold intervals, such as figure 1 shown, including the following steps:

[0019] S1: Input the grayscale image of the surface image of the detected part;

[0020] S2: Obtain the defect feature value vector of the gray-scaled image of the detected part and the threshold intervals to which the defects belong among multiple threshold intervals of defects;

[0021] S3: Calculate the defect type corresponding to the defect feature value vector by using a minimum distance classifier according to the threshold interval to which the defect belongs.

[0022] Specifically, in step S1, an industrial camera is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com