Emulsion stability test instrument and test method of oil-based drilling liquid

An oil-based drilling fluid and emulsification stability technology, applied in the field of oil deep well drilling, can solve problems such as inability to provide high temperature and high pressure, and inability to accurately measure the emulsification stability of high temperature and high pressure oil-based drilling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

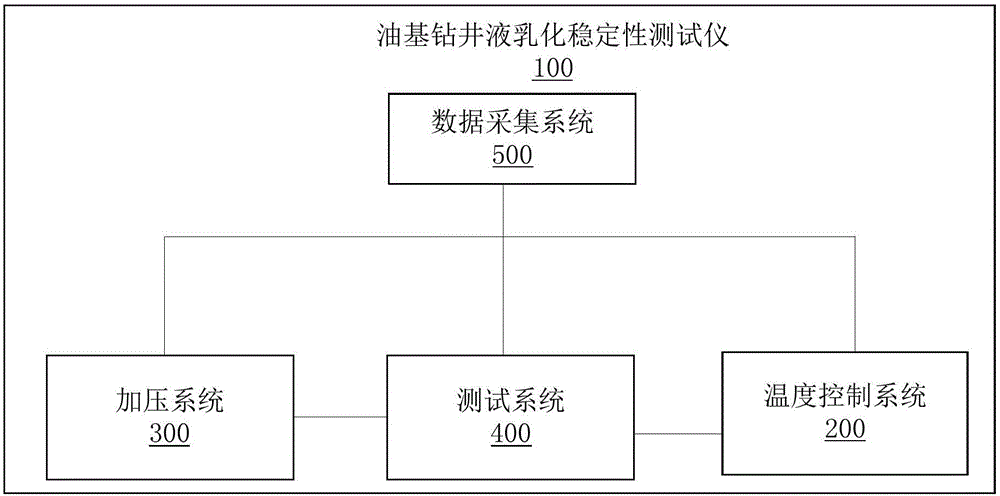

[0034] See figure 1 , is an oil-based drilling fluid emulsion stability tester 100 provided by the embodiment of the present invention, including a temperature control system 200, a pressurization system 300, a test system 400 and a data acquisition system 500; the pressurization system 300 and the The test system 400 is connected, the temperature control system 200 is electrically connected to the test system 400 , and the data acquisition system 500 is electrically connected to the pressurization system 300 , the temperature control system 200 and the test system 400 .

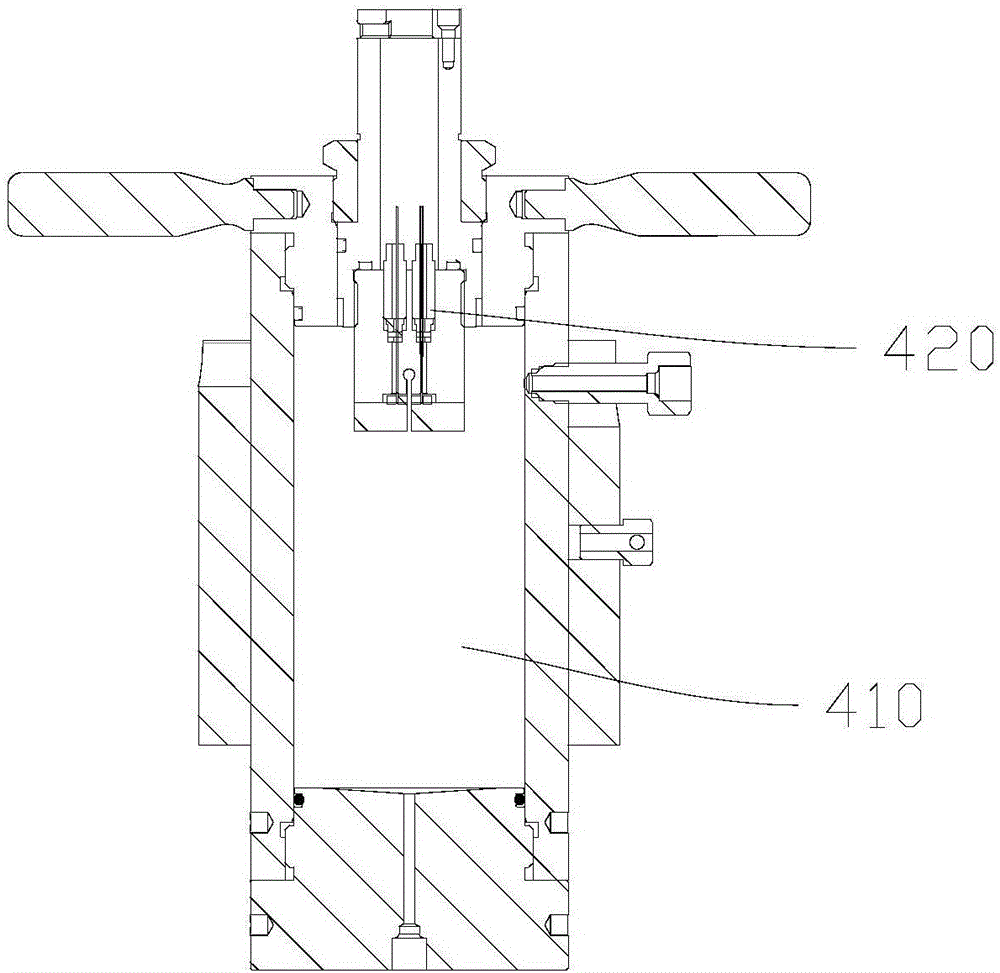

[0035] See figure 2 , is a schematic diagram of the circuit structure of the test kettle body 410 and the test electrode 420 provided by the preferred embodiment of the present invention. The test system 400 includes a test kettle body 410, a test electrode 420 and a power supply, the power supply is electrically connected to the test electrode 420, the test electrode 420 is electrically connected to the t...

Embodiment 2

[0060] See Figure 6 , the oil-based drilling fluid emulsion stability test method 600 provided in the embodiment of the present invention is applied to the oil-based drilling fluid emulsion stability tester 100, and the oil-based drilling fluid emulsion stability tester 100 includes a temperature control system 200, a pressurized The system 300 , the test system 400 and the data acquisition system 500 , the test system 400 includes a test kettle body 410 and a test electrode 420 . The methods described include:

[0061] Step S610, the temperature control system 200 heats the test kettle body 410 to a preset temperature, and the pressurization system 300 pressurizes the test kettle body 410 to a preset pressure;

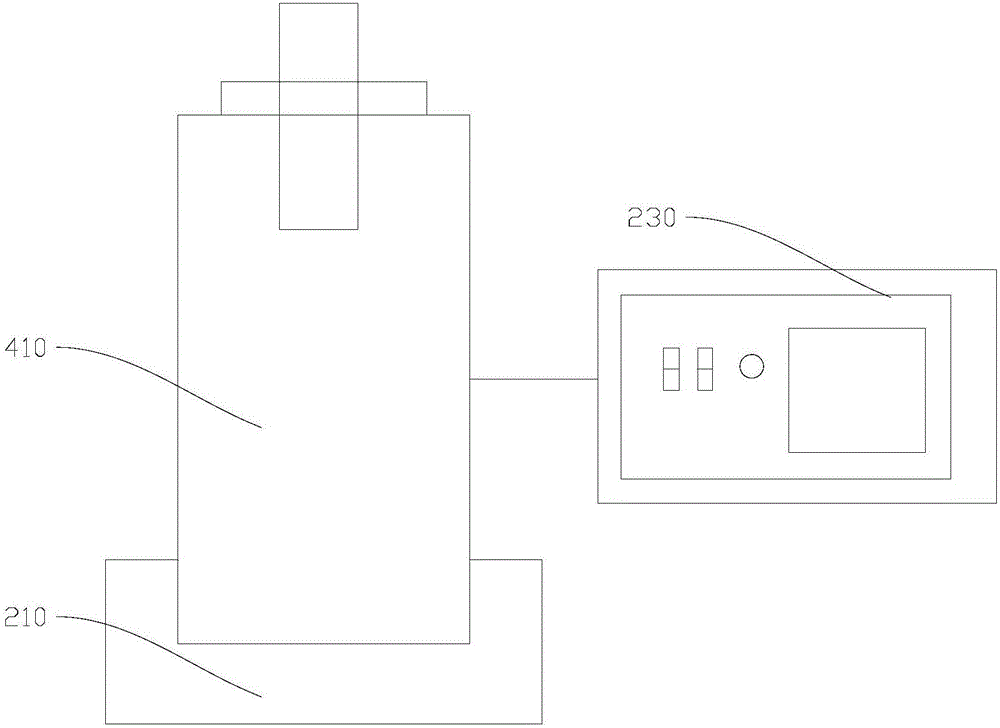

[0062]The oil-based drilling fluid to be tested is injected into the test kettle body 410, and the test kettle body 410 is heated by the temperature control system 200. Specifically, the temperature control system 200 includes a heater 210 and a temperature controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com