Equipment for full-automatically and rapidly checking residual materials in SMD material trays

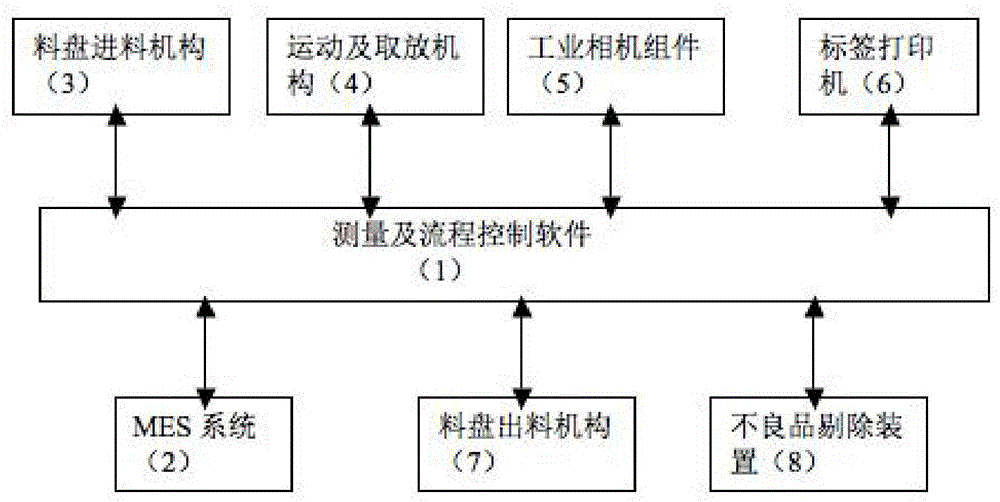

A fully automatic, tray technology, which is applied to the counting of instruments, counting objects, and items shipped through conveying devices, etc., can solve the problems of unfixed tray weight, large quantity error, and low efficiency, and achieve high error resolution and uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

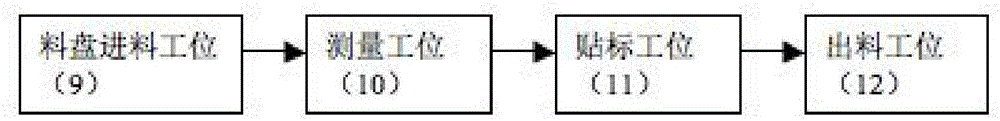

Method used

Image

Examples

Embodiment

[0035] Surplus material quantity measurement and calculation method of the present invention:

[0036] Calculation formula for remaining material:

[0037] For a certain material A, set the quantity of the full plate as N, and the radius when the plate is full is R 满 , when the disk is empty, the radius is R 空 , the radius of the current remaining material is R 现 , adjustment factor K 1 , K 2 ,

[0038] Then, the amount of remaining material = (N ) K 1 +K 2

[0039] The industrial camera takes photos and reads the content of the tray information label, uploads the MES system to check the information, and at the same time obtains the type of tray, and obtains the number of full trays N and half full tray R 满 , inner diameter of the empty disk R 空 , adjustment factor K 1 、K 2 ;

[0040] An industrial camera takes pictures to measure the inner diameter R of the tray 空 , compare and confirm with the inner diameter of the empty tray obtained before, if not the same, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com