Patents

Literature

39 results about "Process control software" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process Control Software. ALSO CALLED: Industrial Process Control Software. DEFINITION: Software that automatically monitors and controls a process to insure the output of the process conforms to pertinent manufacturing specifications.

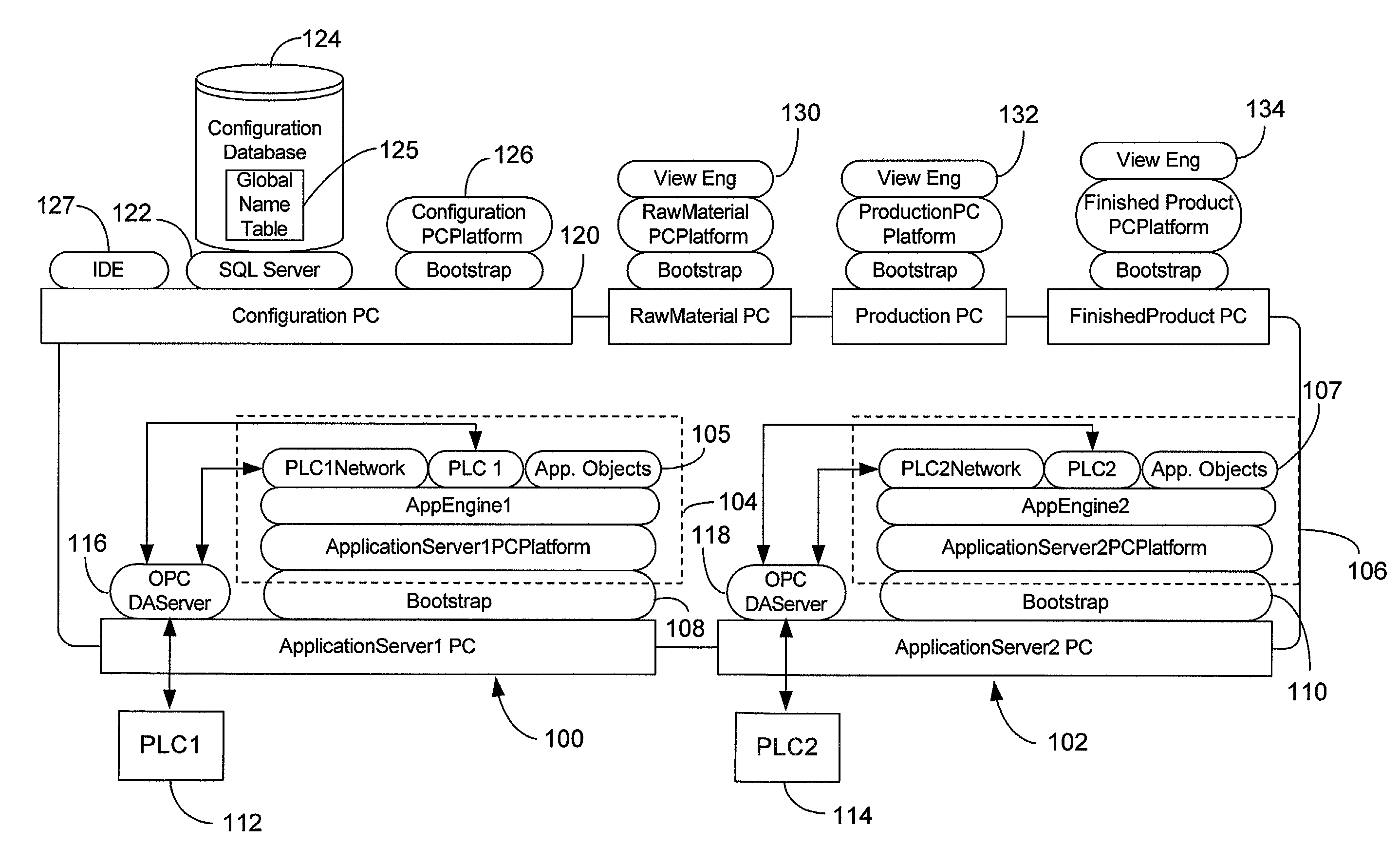

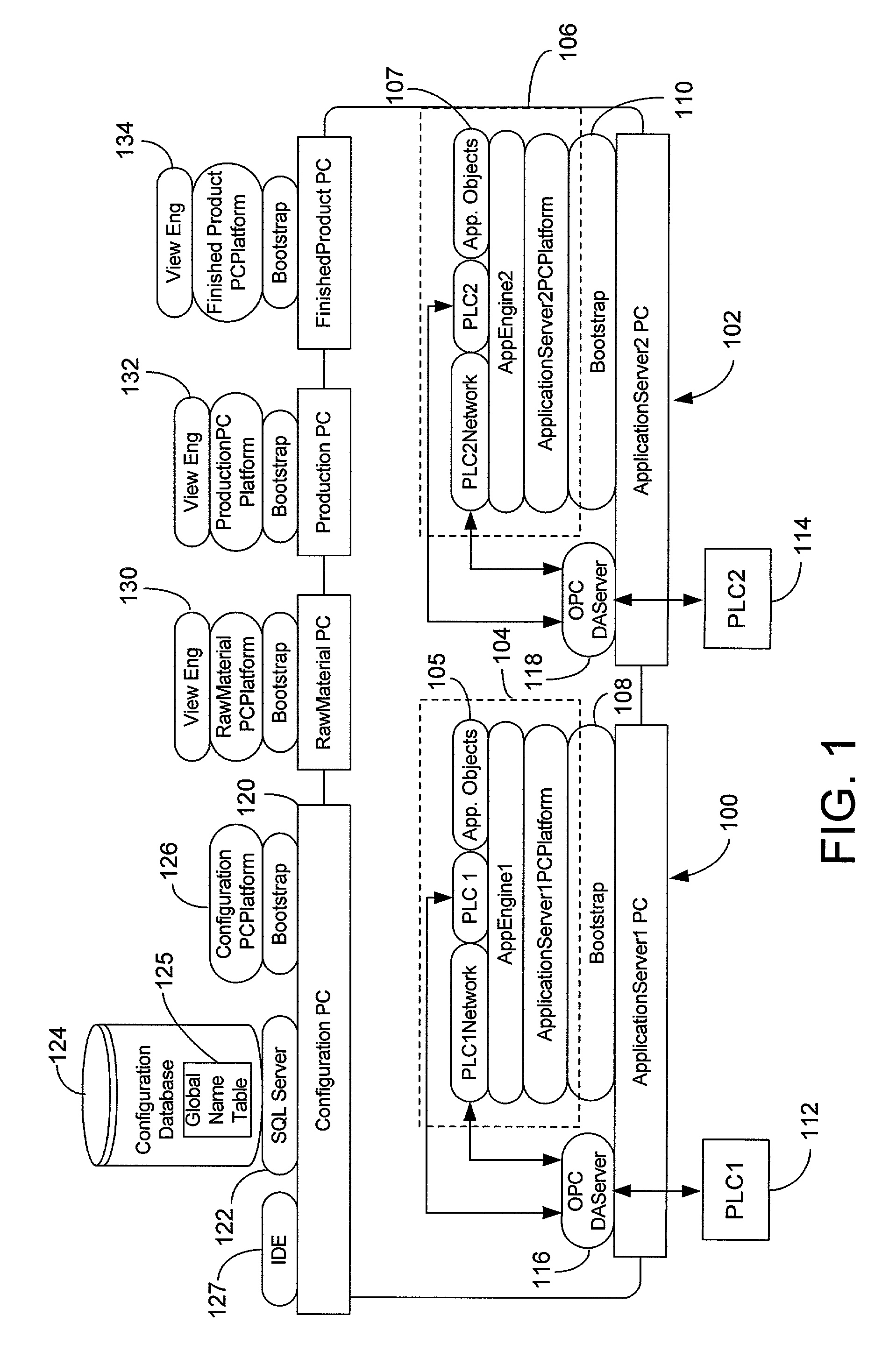

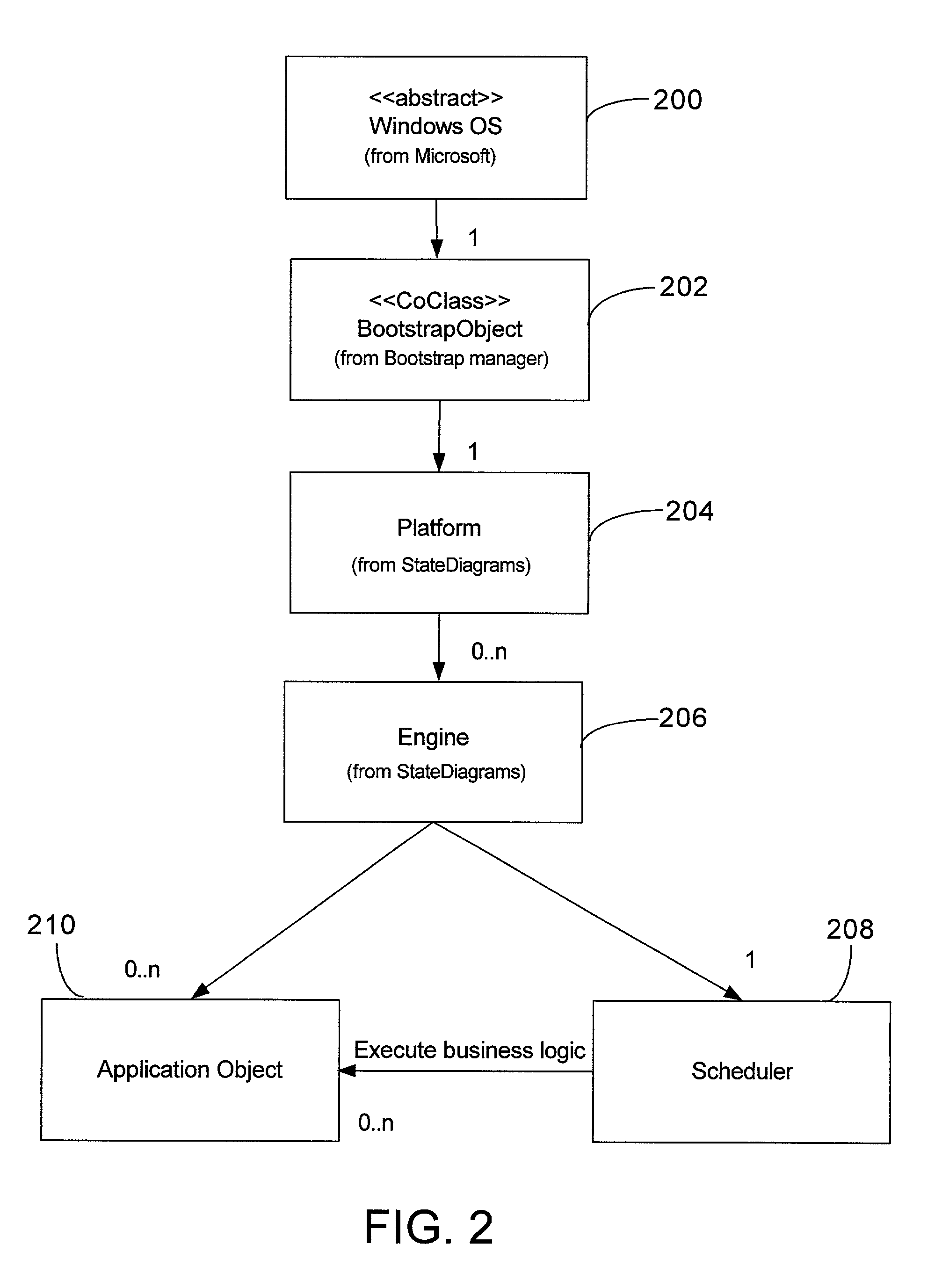

Installing supervisory process control and manufacturing software from a remote location and maintaining configuration data links in a run-time environment

ActiveUS7496911B2Lower the volumeProgram loading/initiatingSoftware simulation/interpretation/emulationSoftware distributionControl system

A method is disclosed, in a supervisory process control system environment, for installing supervisory process control software from a central software deployment server. The software distribution method includes the step of first specifying a software component for a supervisory process control application to be deployed to a remote location and a destination for the software component based upon a distributed application configuration. A software component is conditionally transmitted to the remote supervisory control computer, after the determining step, if the software component for the supervisory process control application is not present at the remote location.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

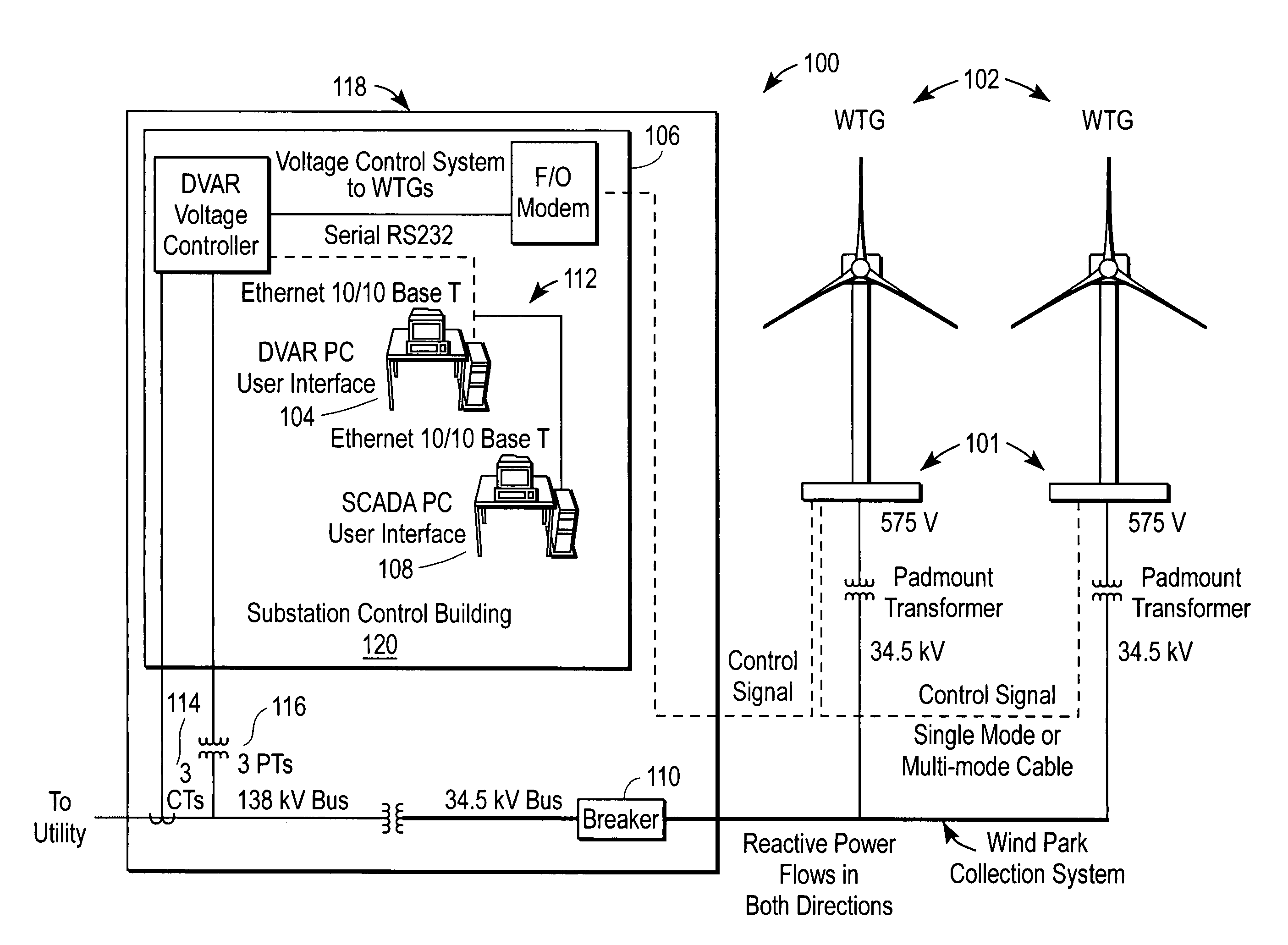

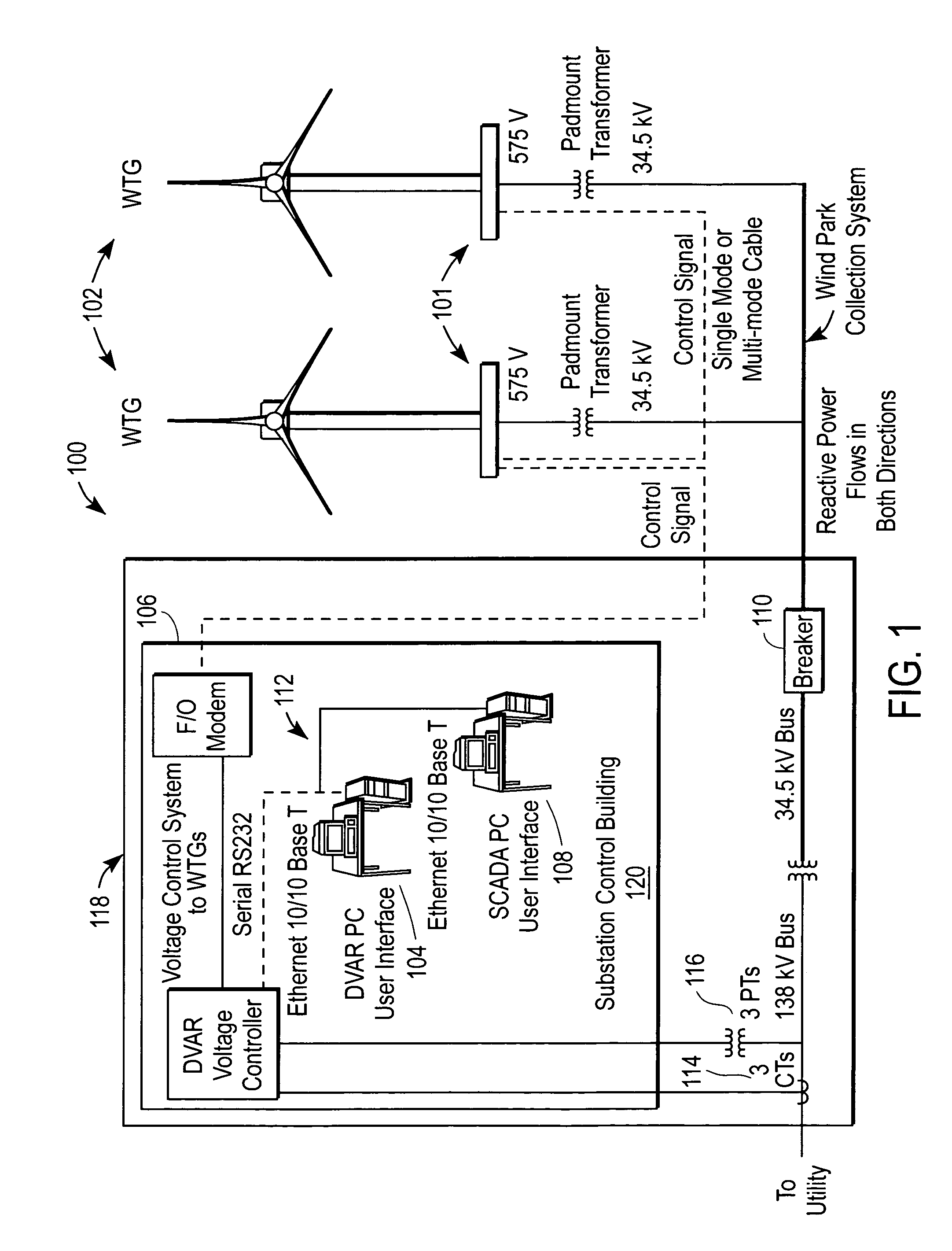

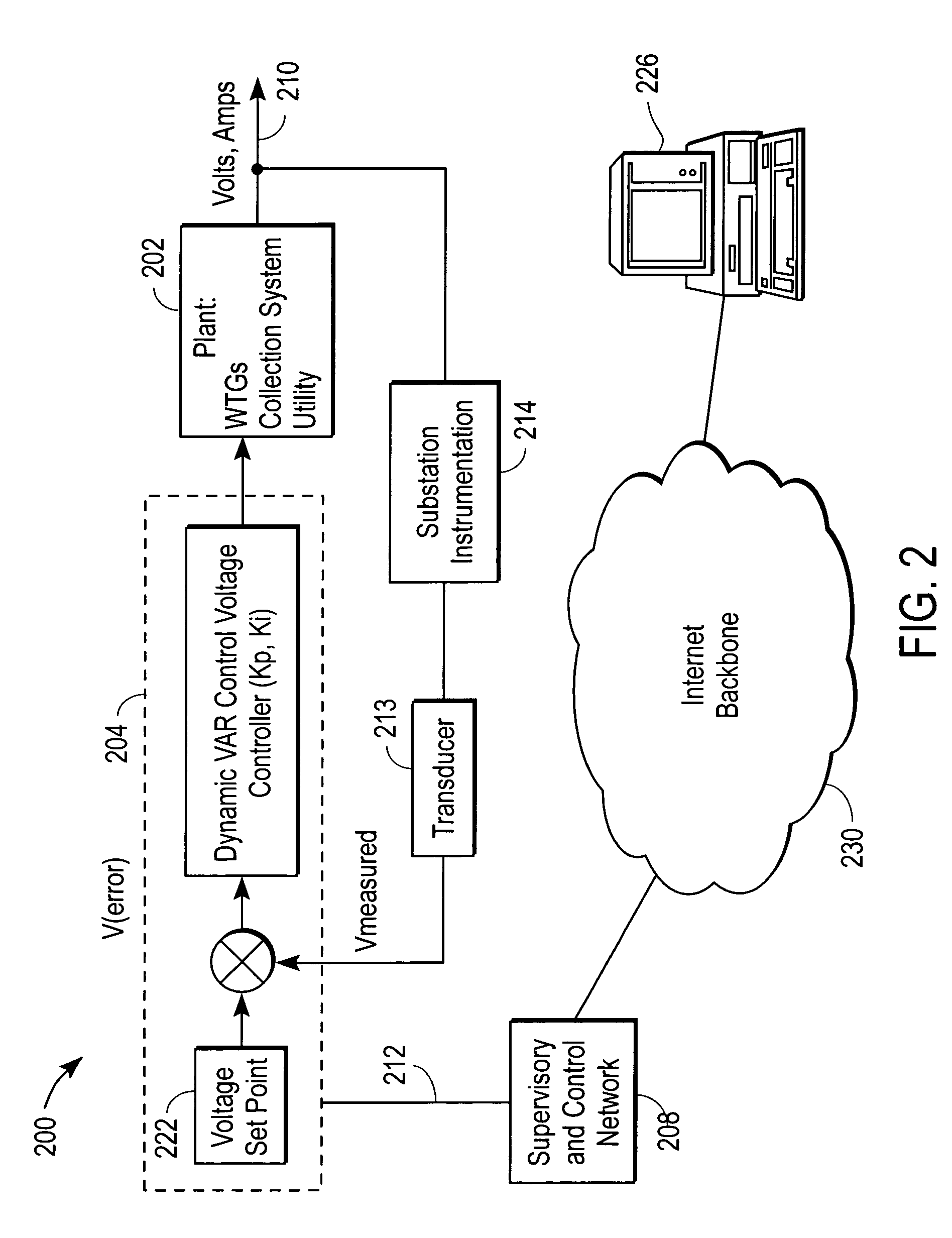

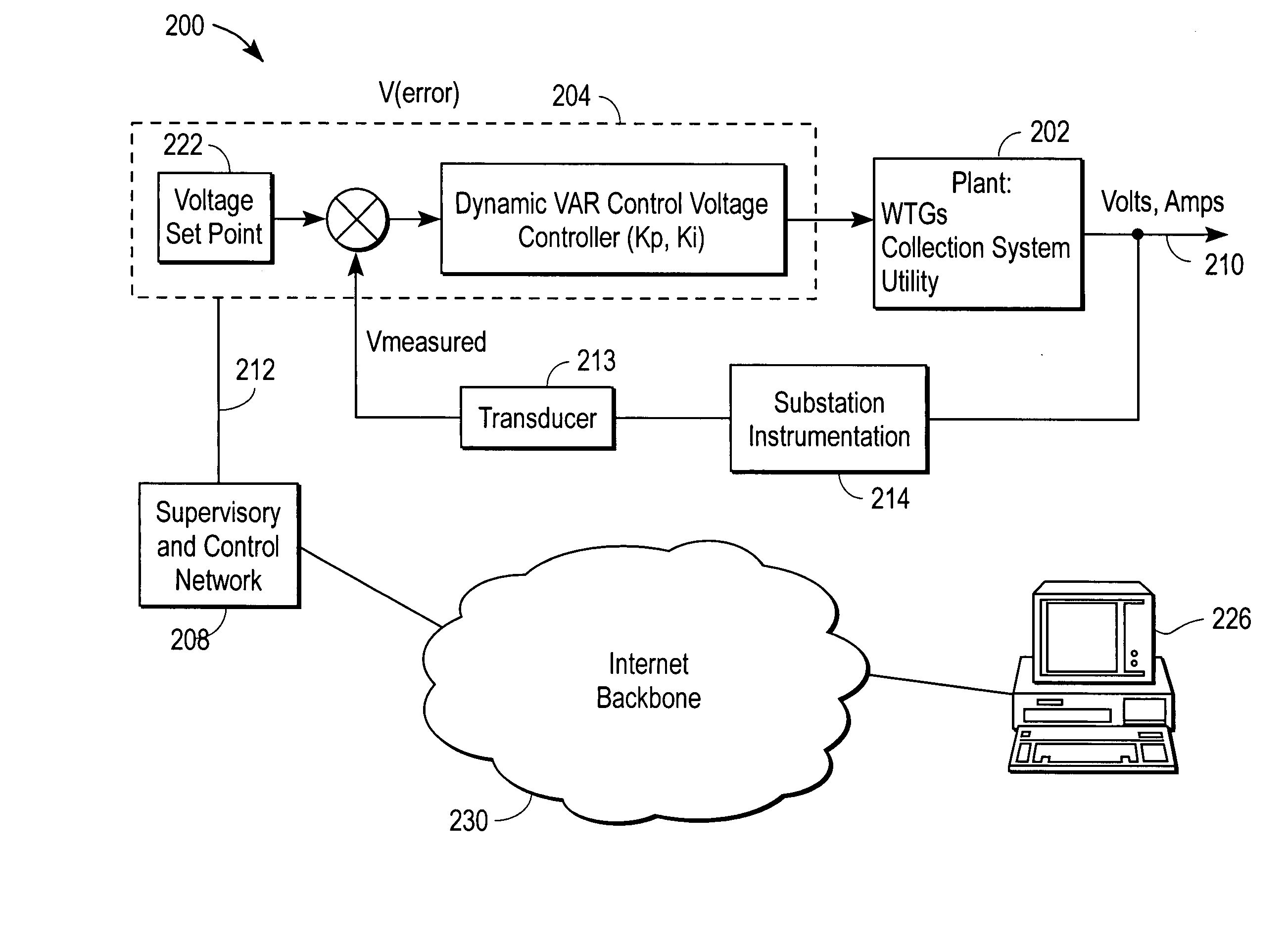

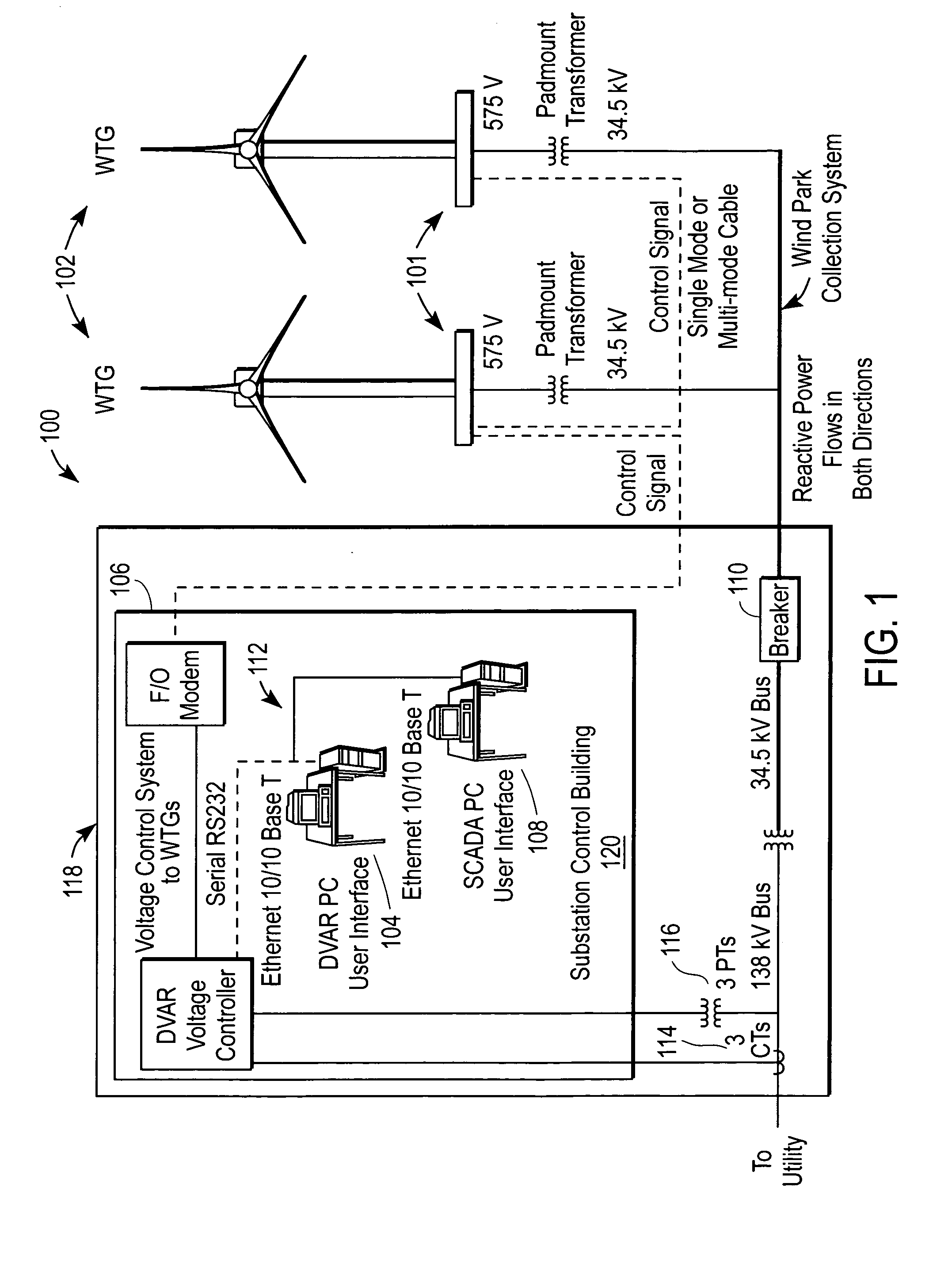

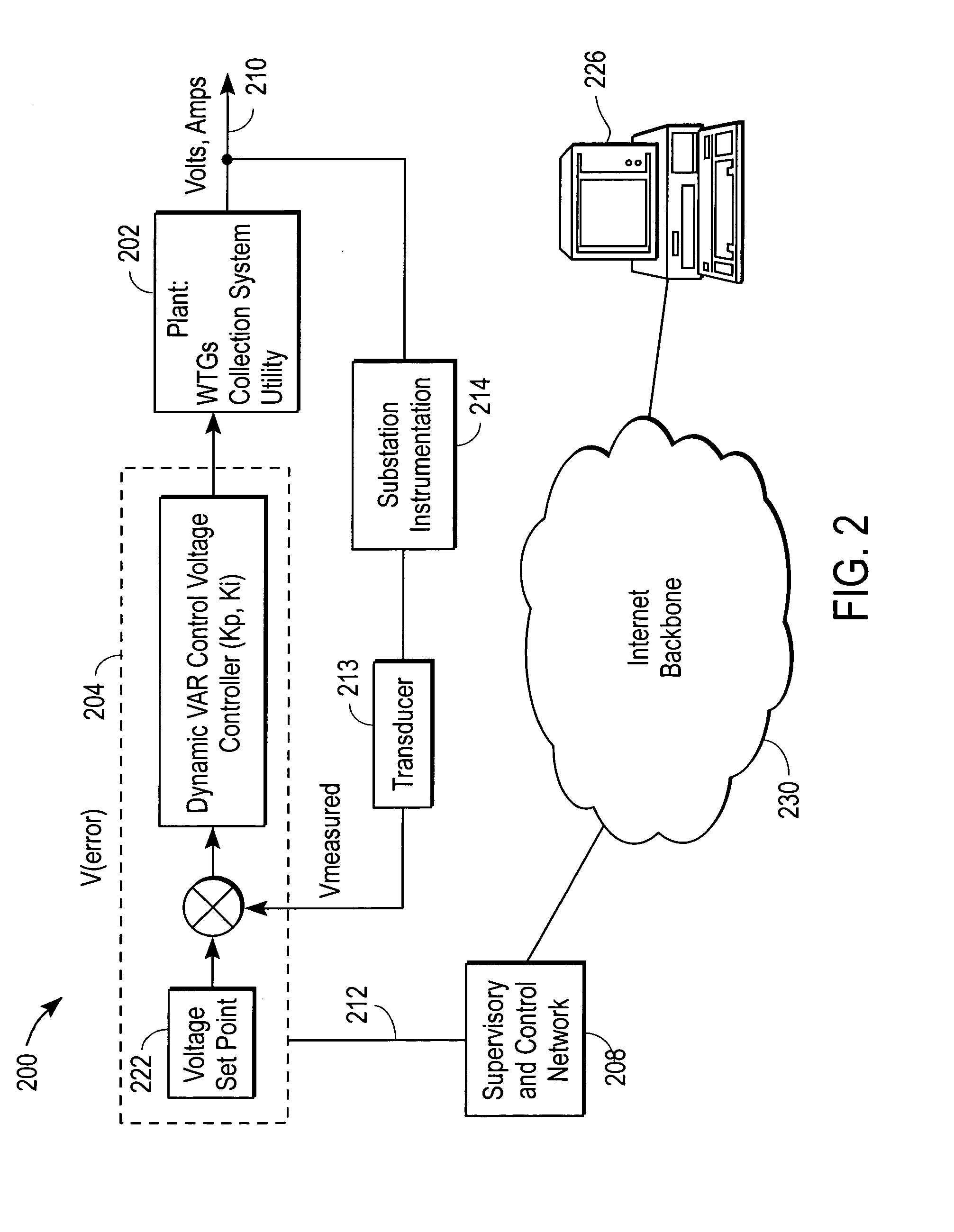

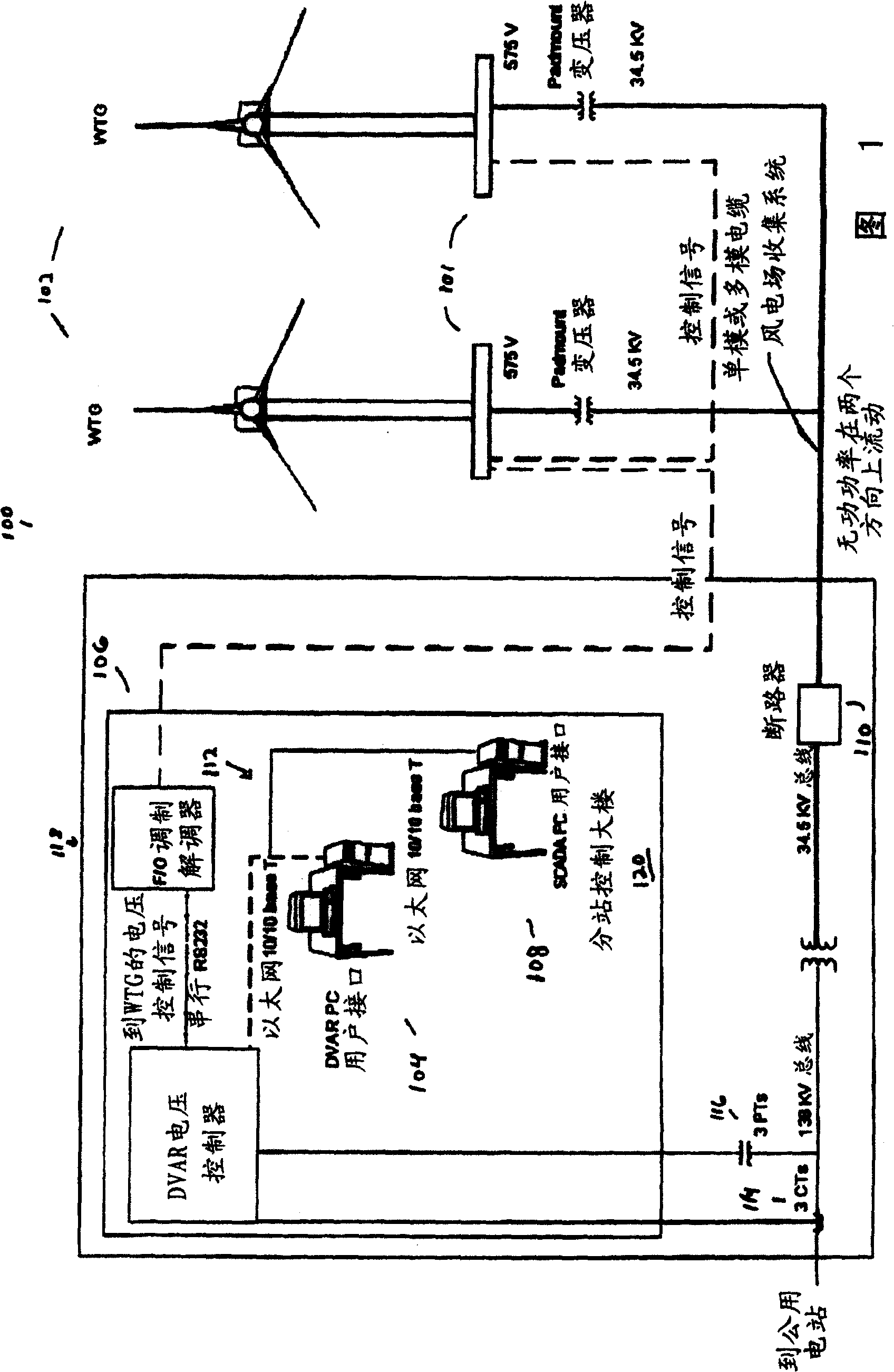

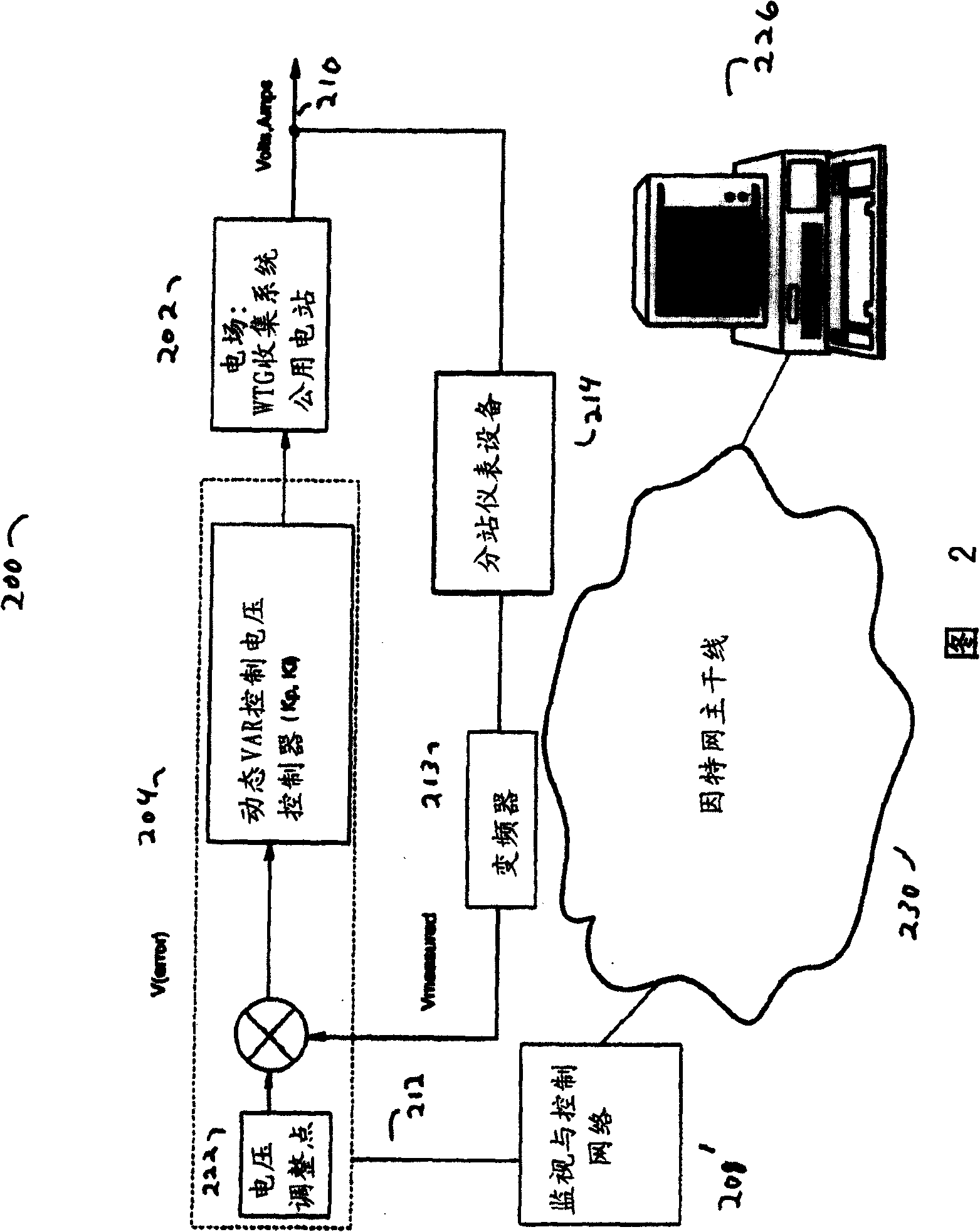

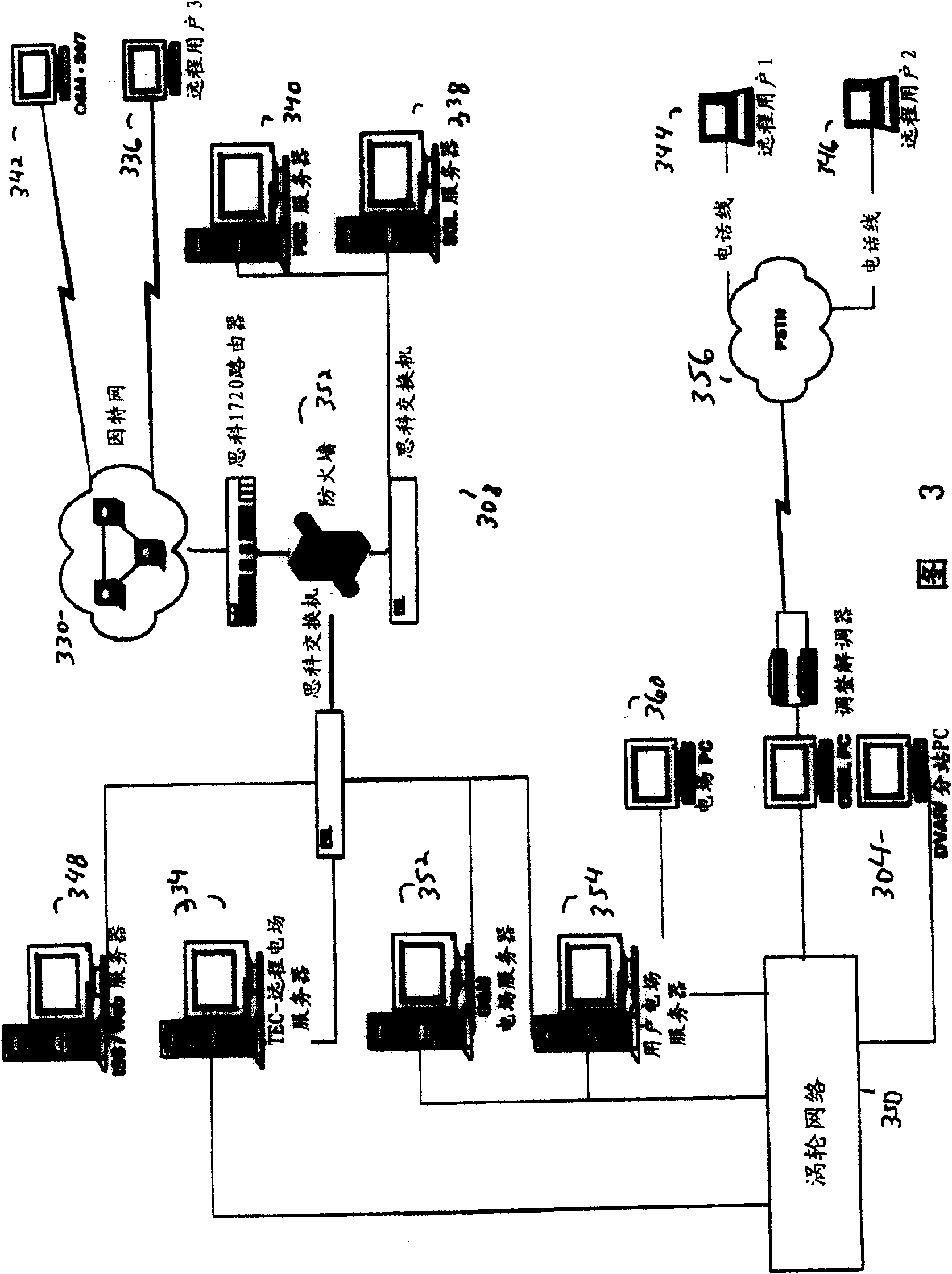

Various methods and apparatuses to provide remote access to a wind turbine generator system

Various methods and apparatus are described in which a power management controller having process control software controls output power characteristics for a group of wind turbine generators. The power management controller also has a network interface configured to allow a user of a supervisory and control network to remotely access and change output power settings of the group of wind turbine generators through a secure connection established over a network connection.

Owner:GENERAL ELECTRIC CO

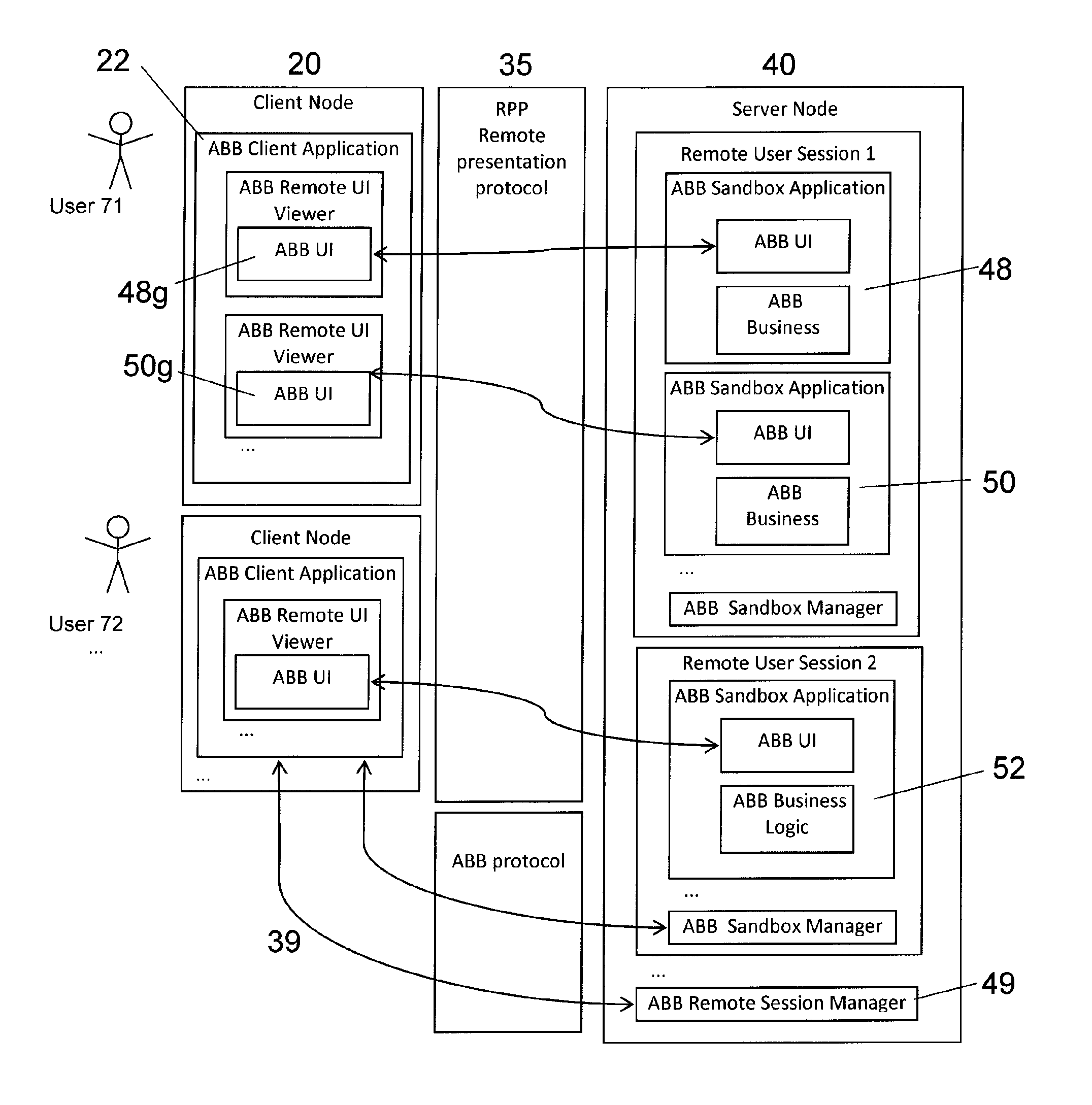

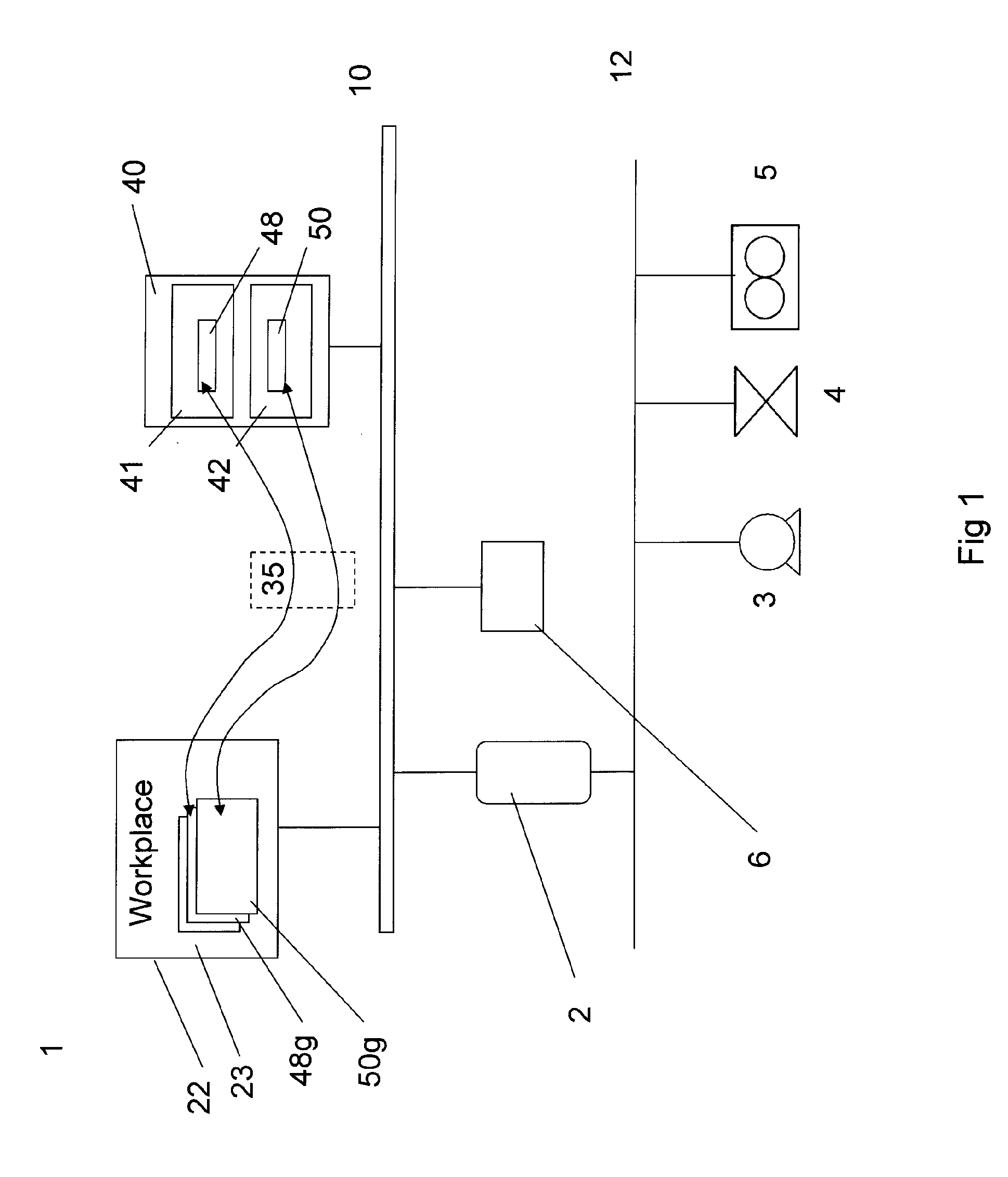

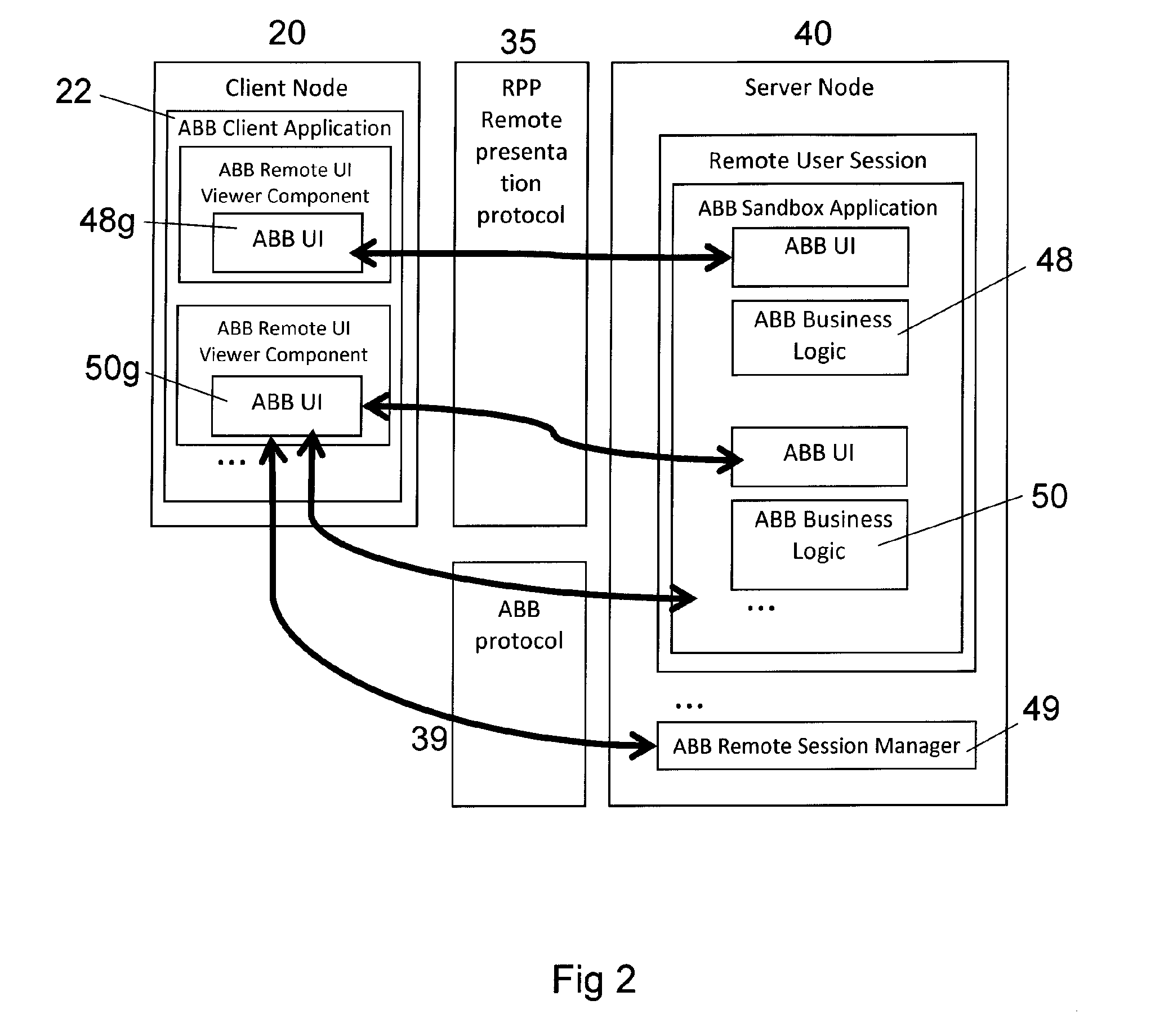

Method For Control In A Process Control System Implemented In Part By One Or More Computer Implemented Run-Time Processes

ActiveUS20120005270A1Programme controlTesting/monitoring control systemsGraphicsGraphical user interface

A method for control in a process control system, where a graphical user interface of said process control system is arranged with graphic representations of one or more control objects for monitoring and / or control of a process or an equipment. The control system GUI is displayed by a control system client application on a computer or workstation. In addition, one or more applications for monitoring and / or controlling at least one said control object are run in a computing process environment separate from said process control system. No code components execute in the same processing space as that running the GUI for the process control system. Any flaw or error in the extended applications cannot affect the control system program controlling an industrial process in real-time. A control system and a computer program are also disclosed.

Owner:ABB (SCHWEIZ) AG

Various methods and apparatuses to provide remote access to a wind turbine generator system

ActiveUS20070266423A1Wind motor controlRandom number generatorsNetwork connectionProcess control software

Various methods and apparatus are described in which a power management controller having process control software controls output power characteristics for a group of wind turbine generators. The power management controller also has a network interface configured to allow a user of a supervisory and control network to remotely access and change output power settings of the group of wind turbine generators through a secure connection established over a network connection.

Owner:GENERAL ELECTRIC CO

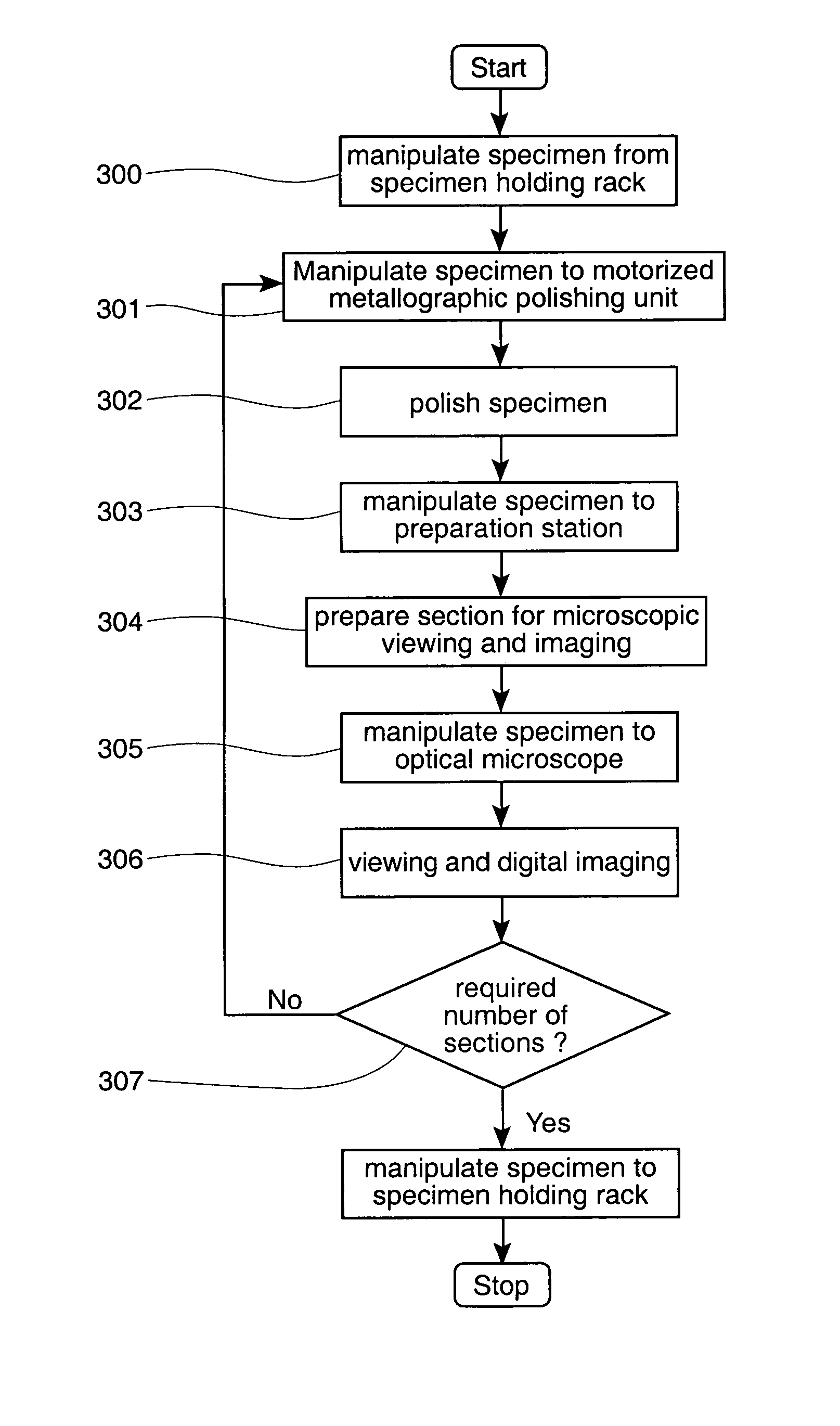

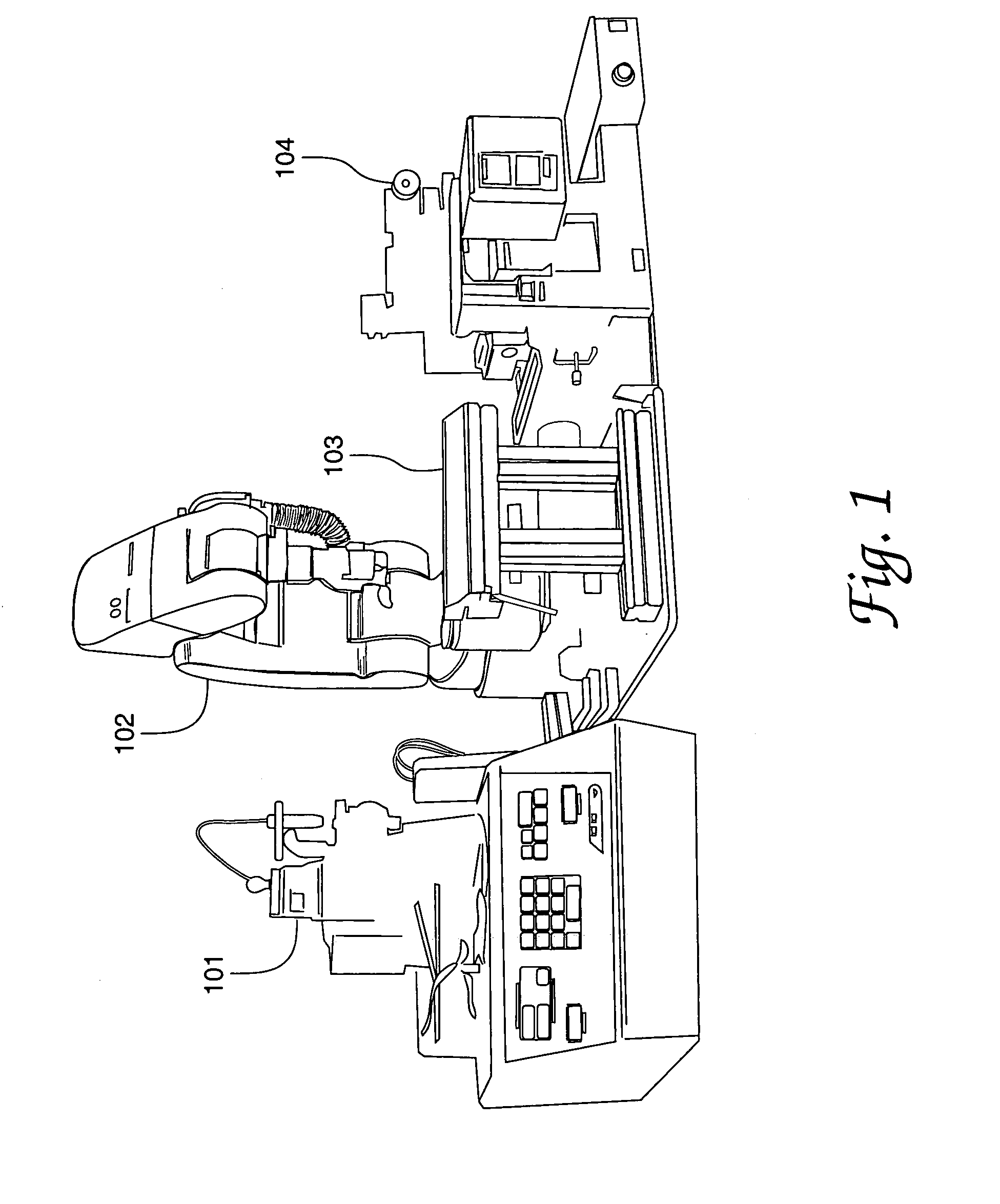

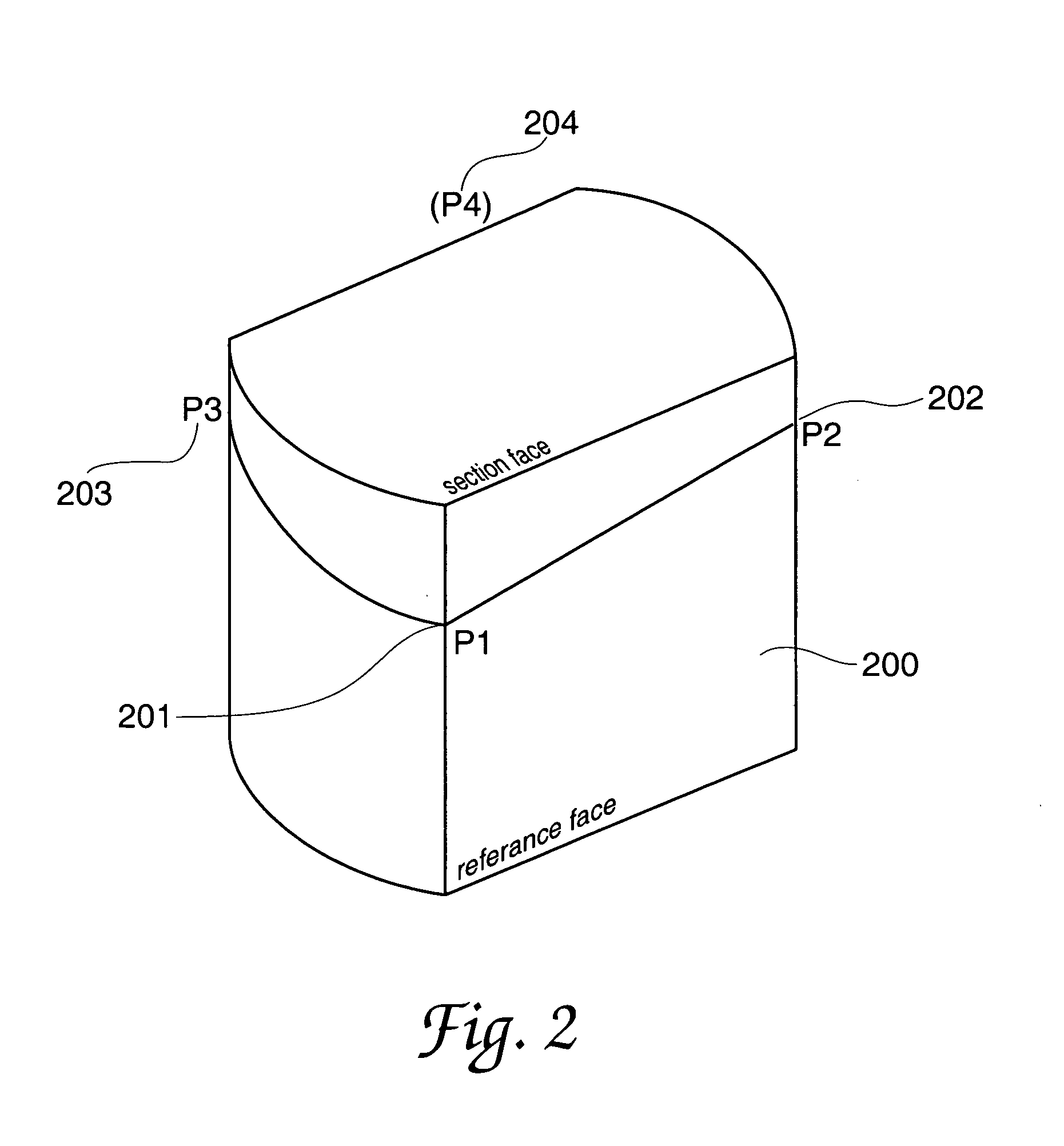

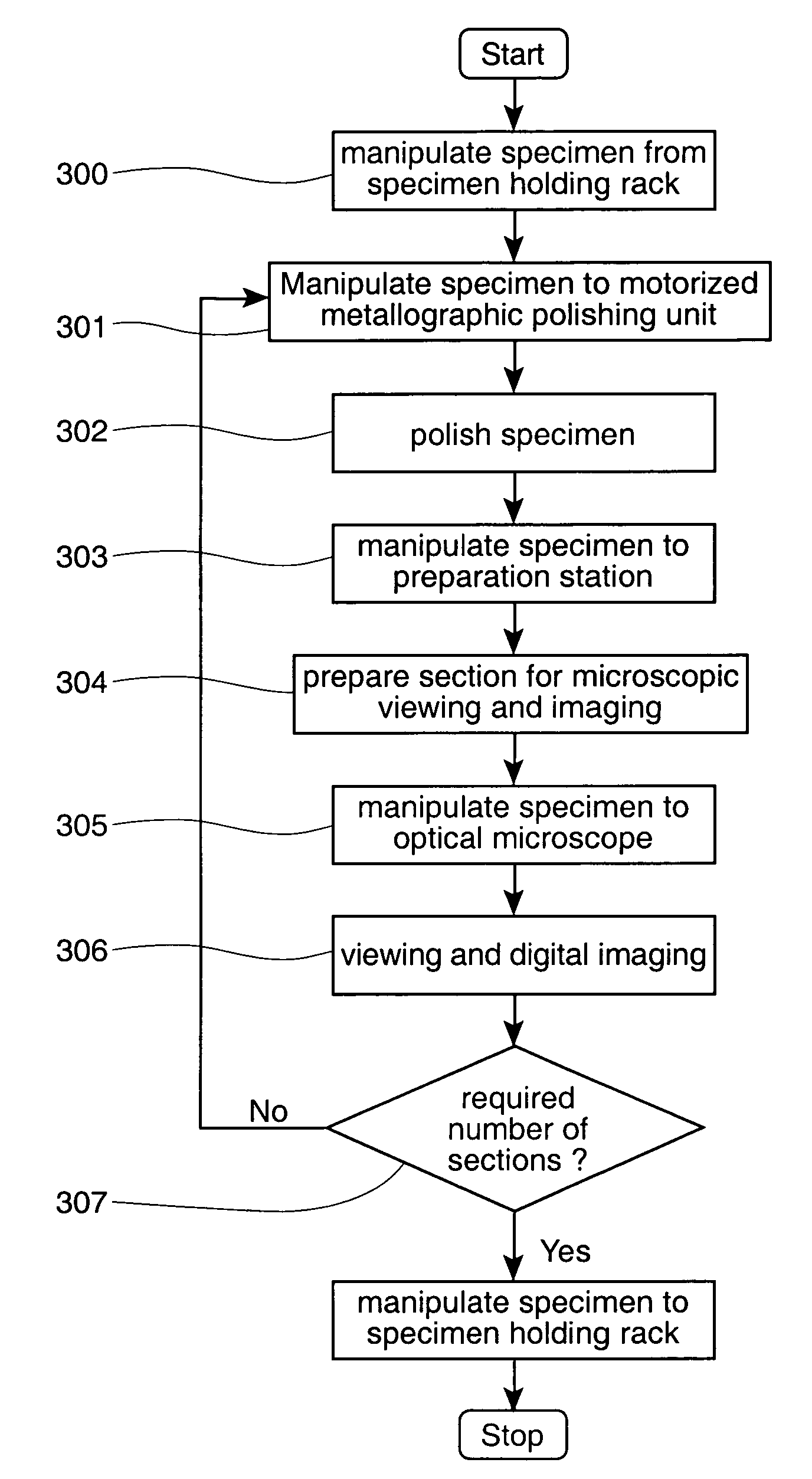

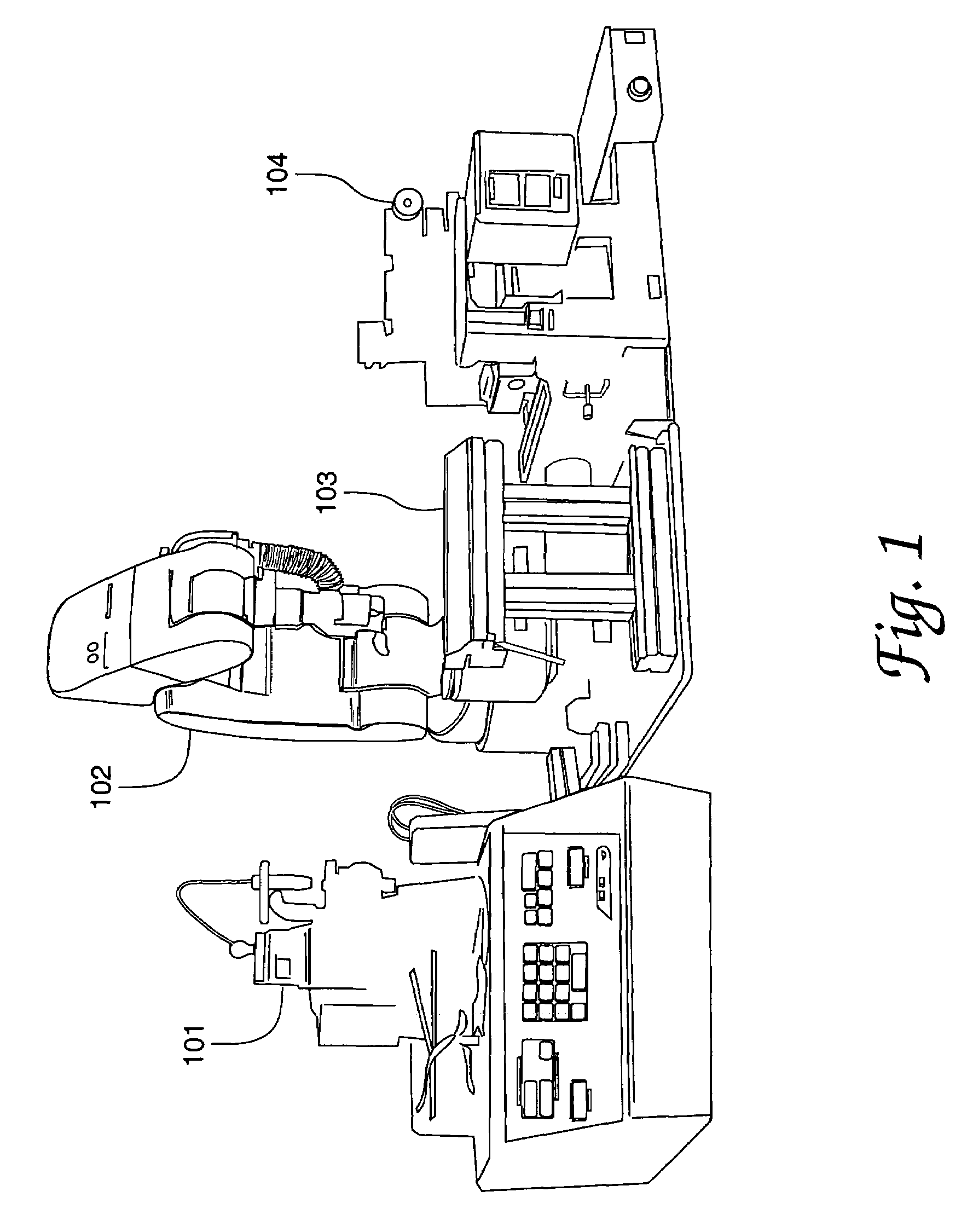

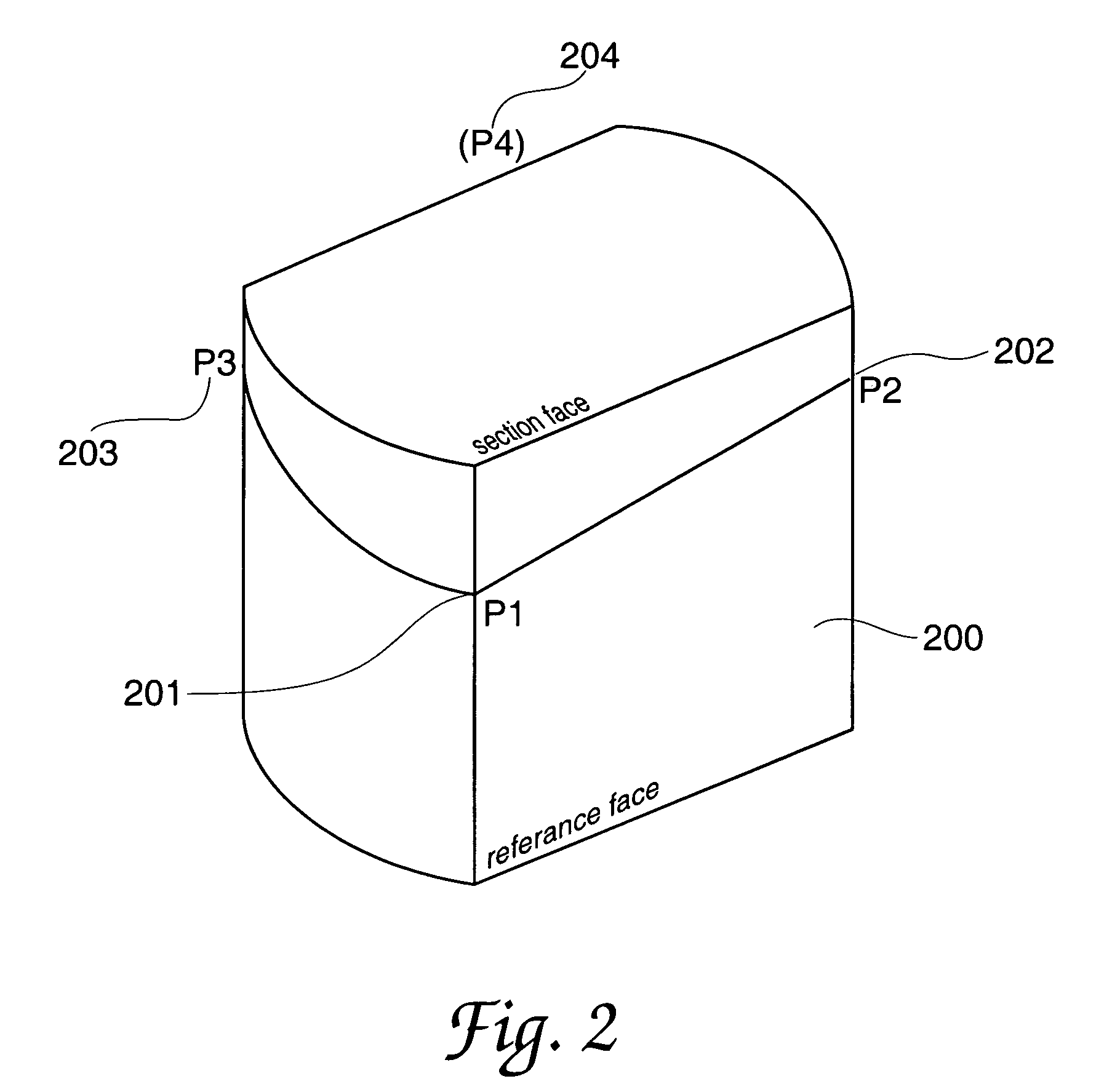

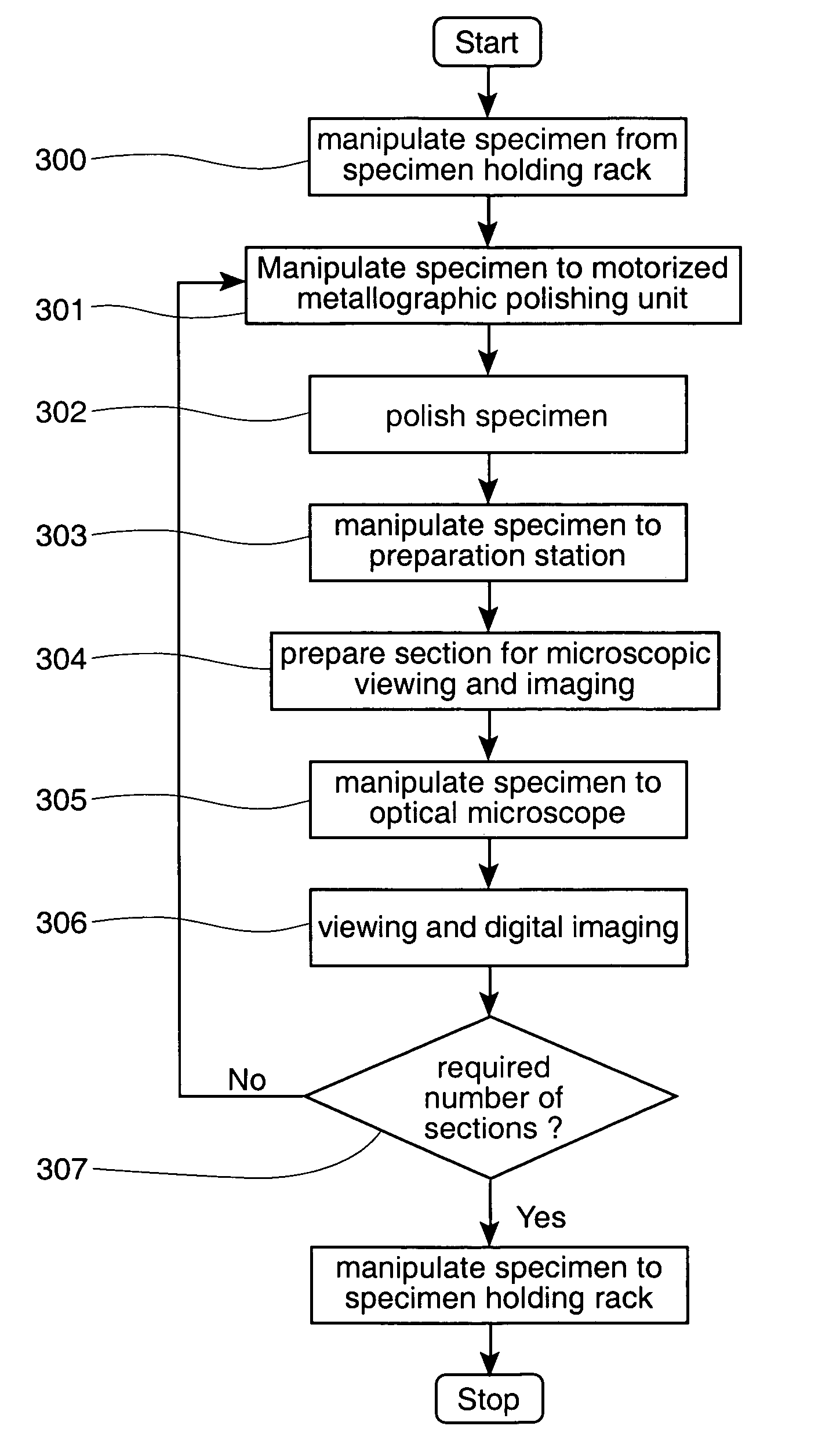

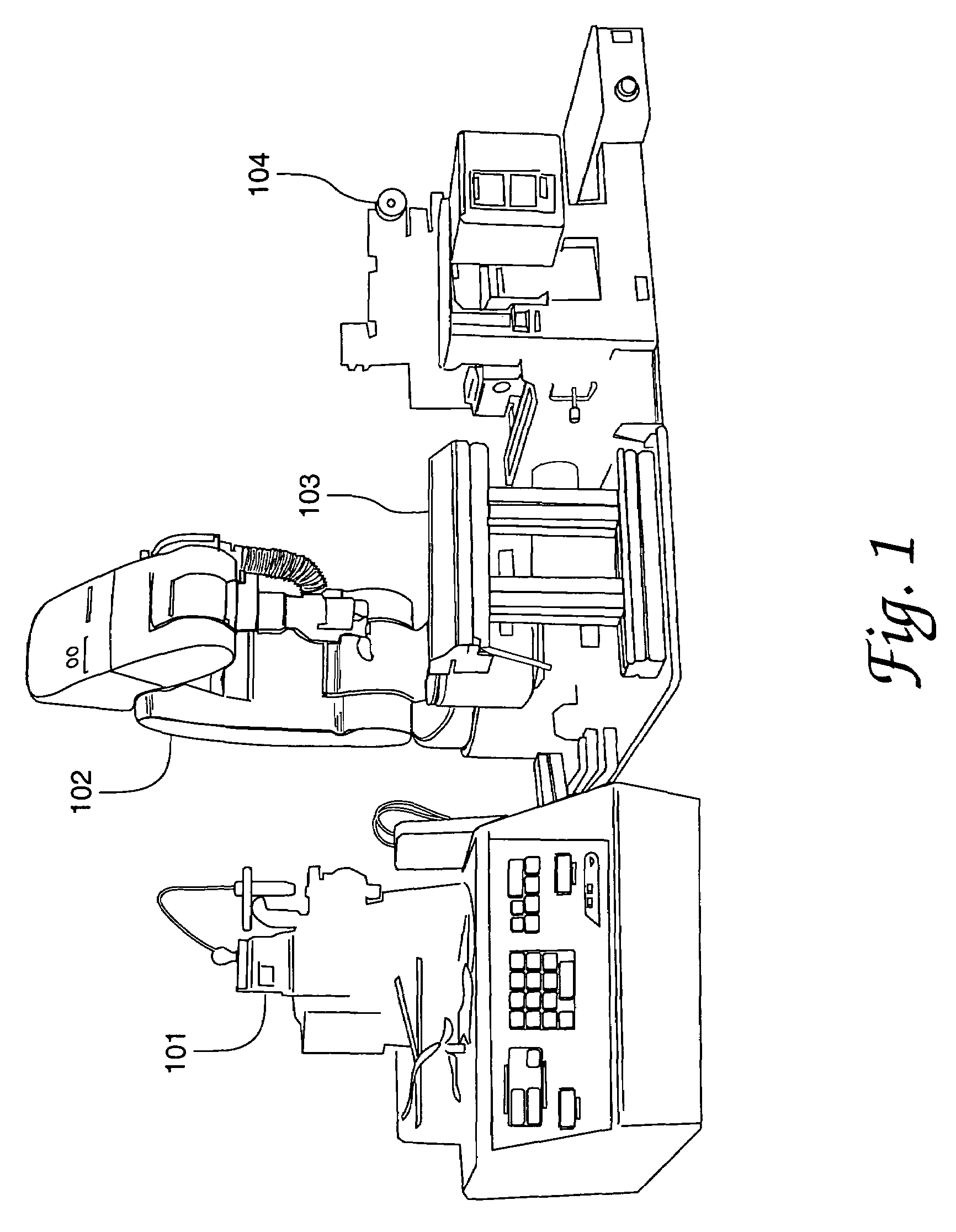

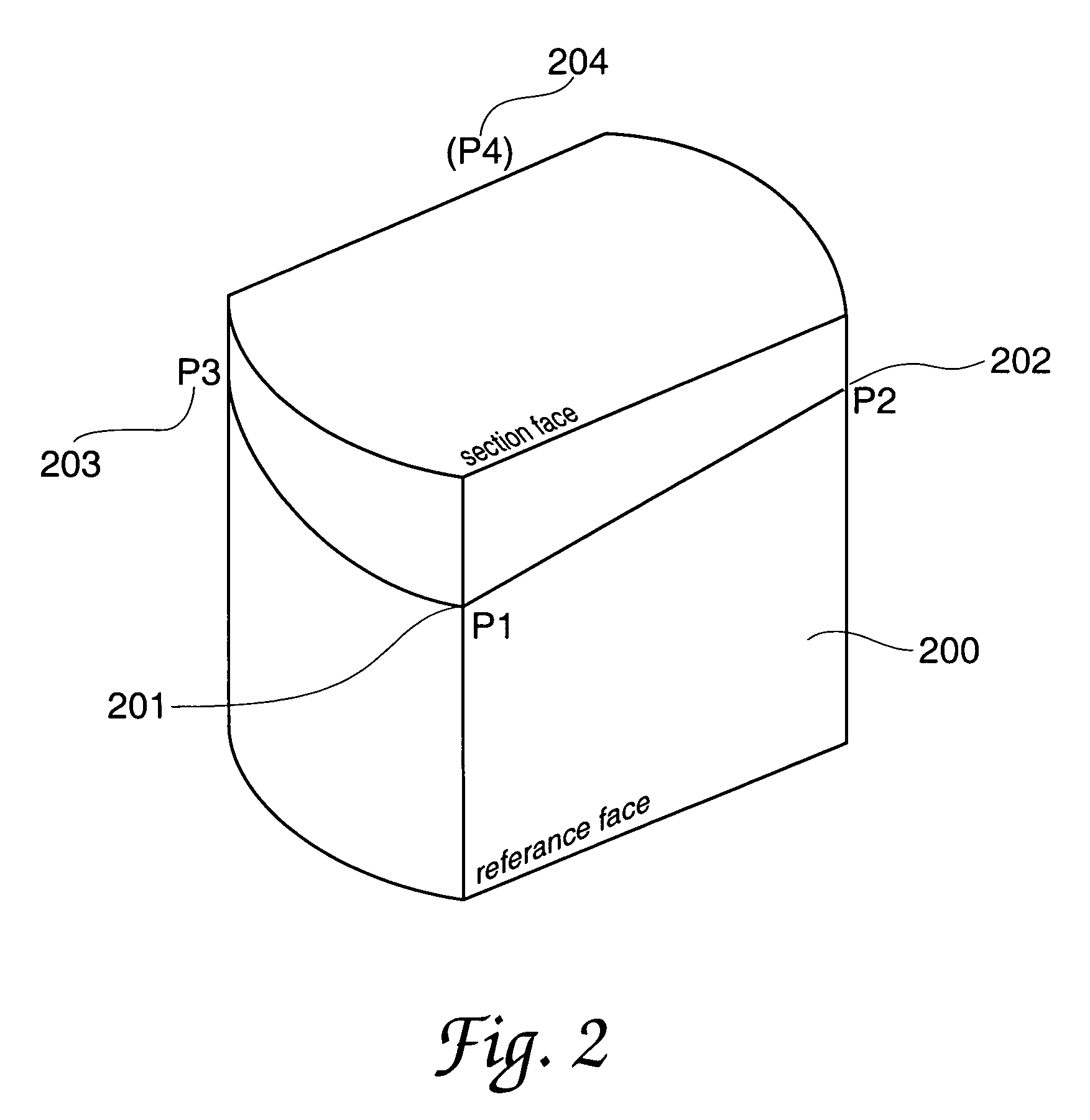

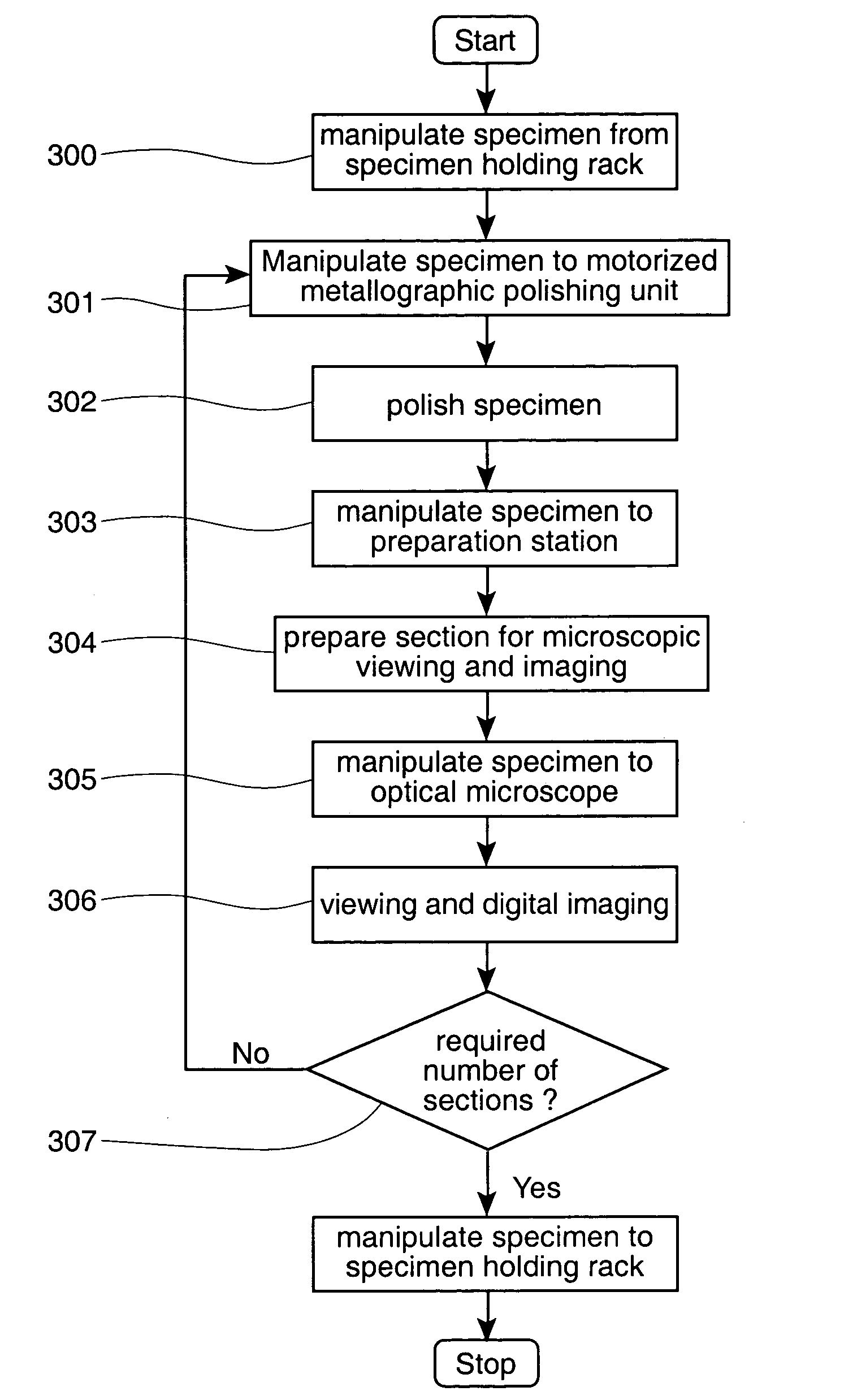

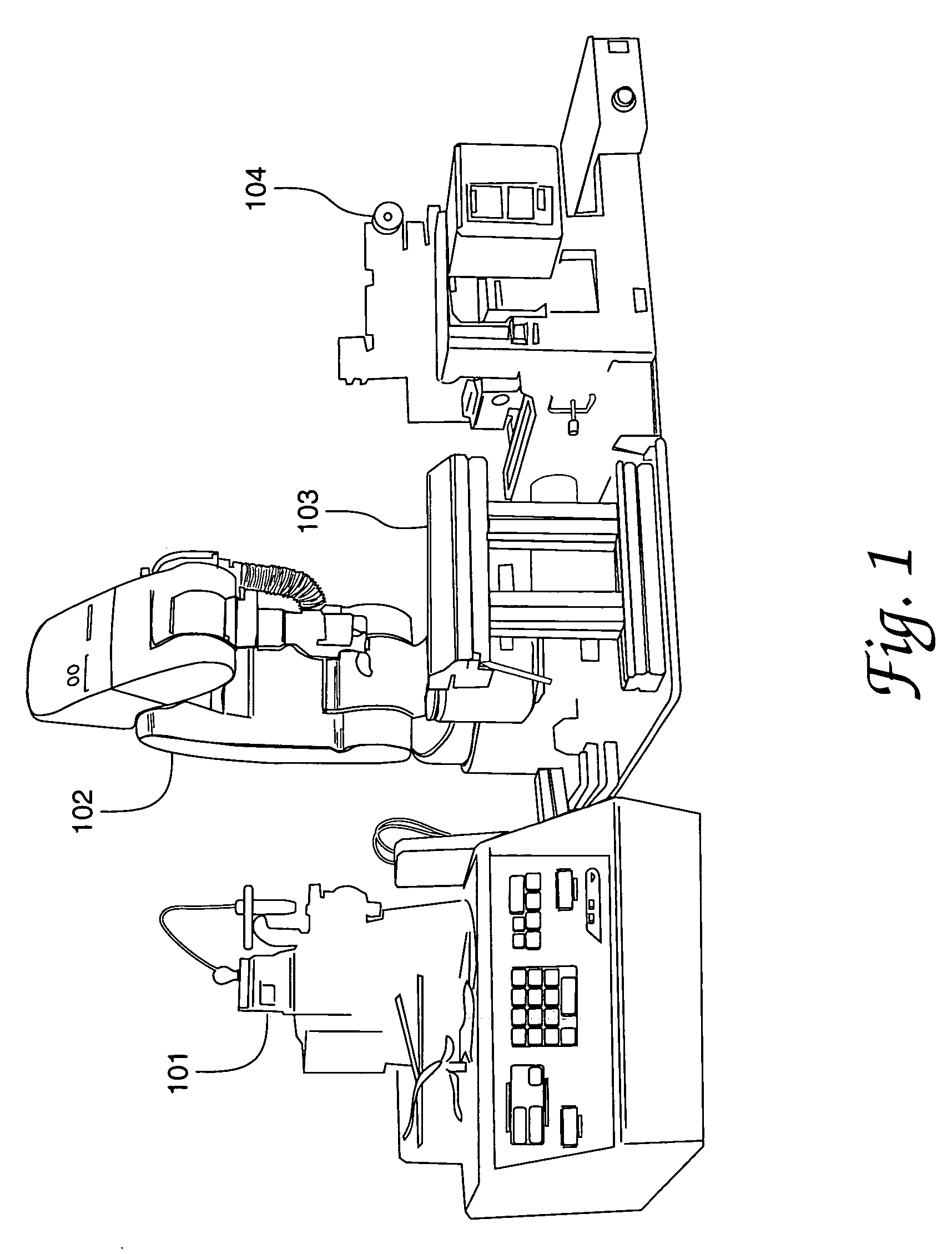

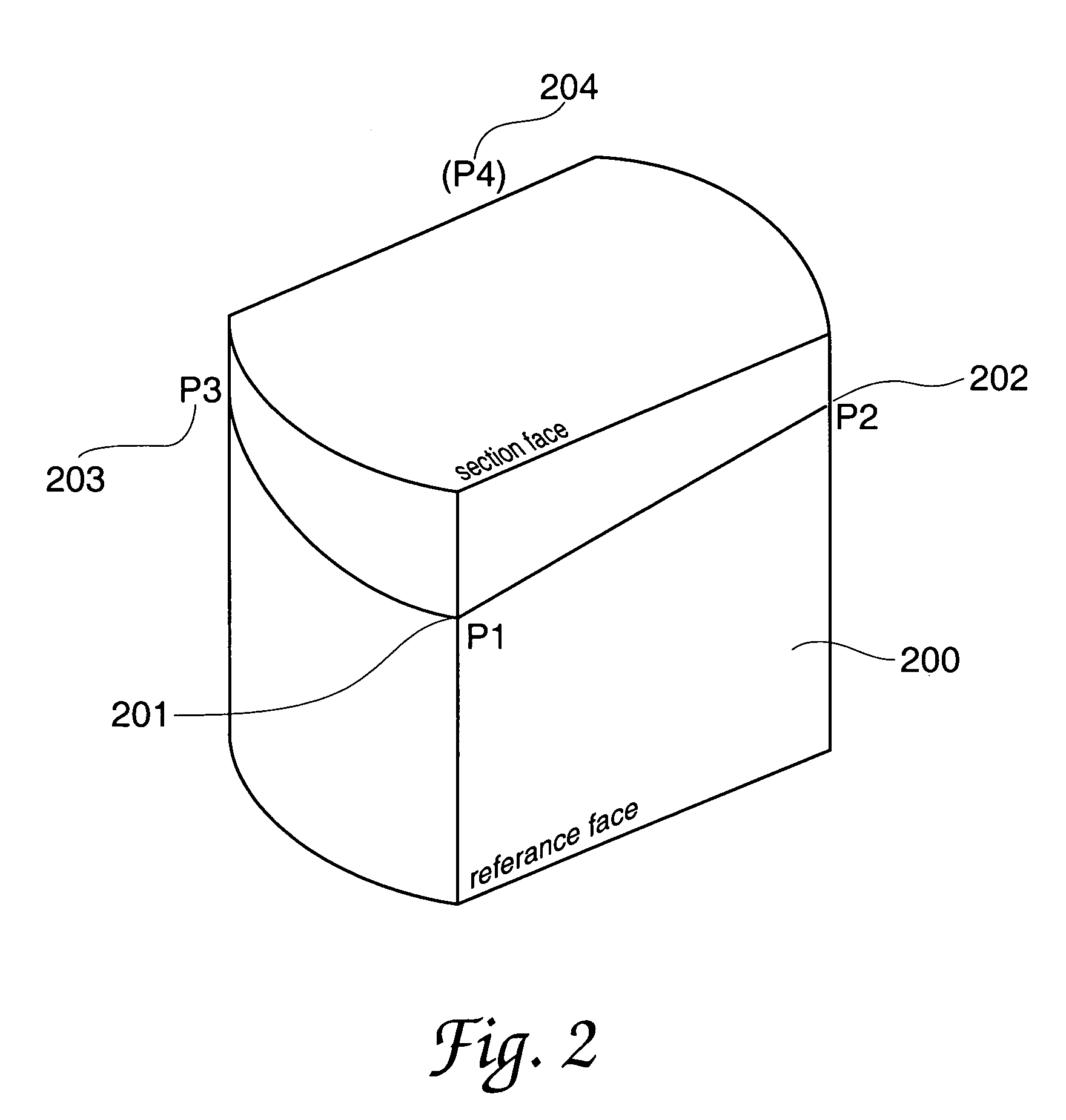

High speed and repeatability serial sectioning method for 3-D reconstruction of microstructures

InactiveUS7317964B1Good precisionIncrease speedWithdrawing sample devicesPreparing sample for investigationDigital imagingReal time analysis

A high speed, high precision, high repeatability serial sectioning method for 3-D reconstruction of microstructure specimens is disclosed. The invention employs high-precision motorized metallographic polishing, viewing and computer controlled digital imaging of microstructure sections of a pre-selected pattern for 3-D microstructure reconstruction. The microstructure specimens are transferred throughout by a robotic manipulator arm providing greater precision and speed and serial-sectioning process control software provides control. The 3-D reconstruction of the invention can be analyzed in real time and can be accomplished in a matter of hours.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

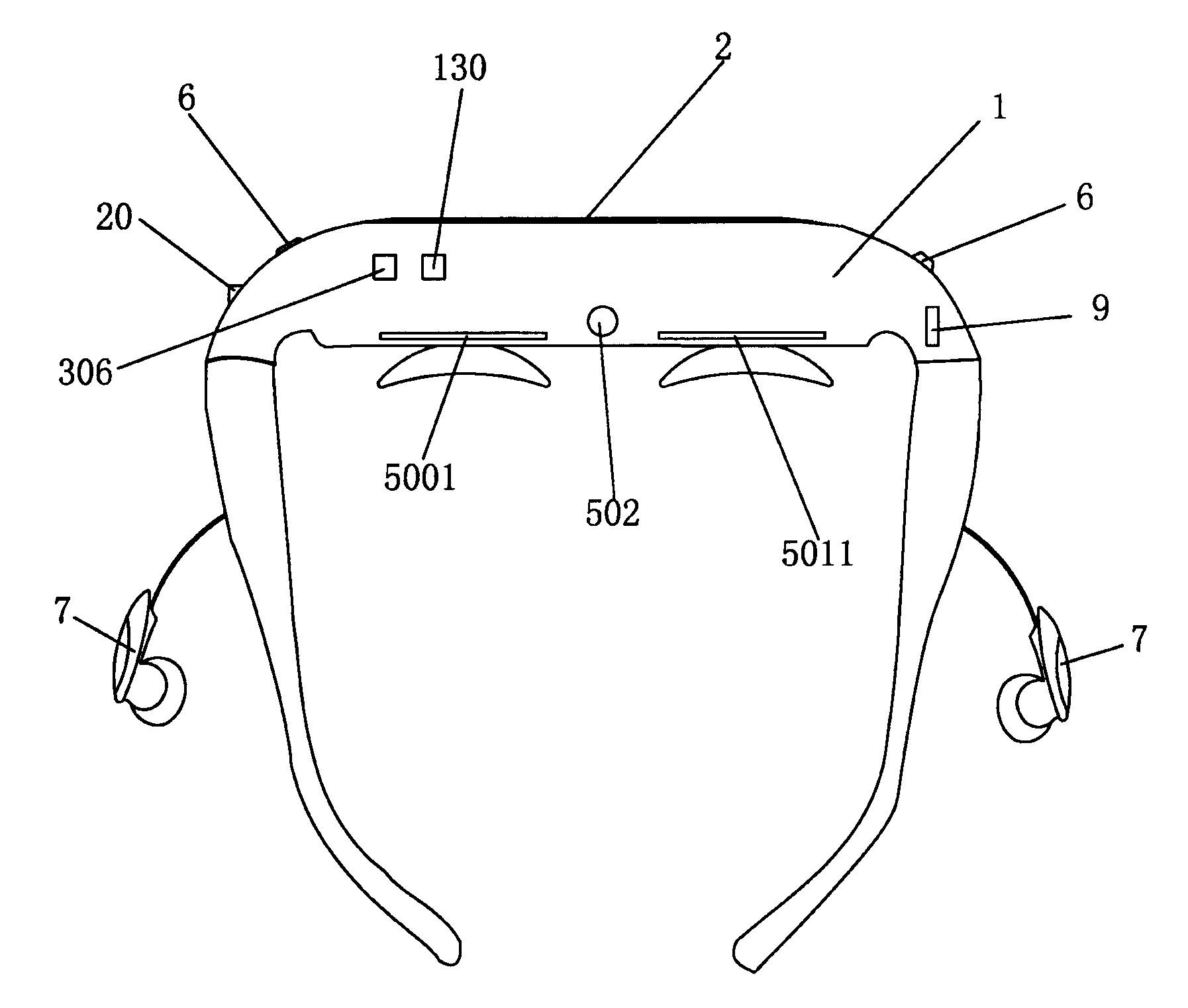

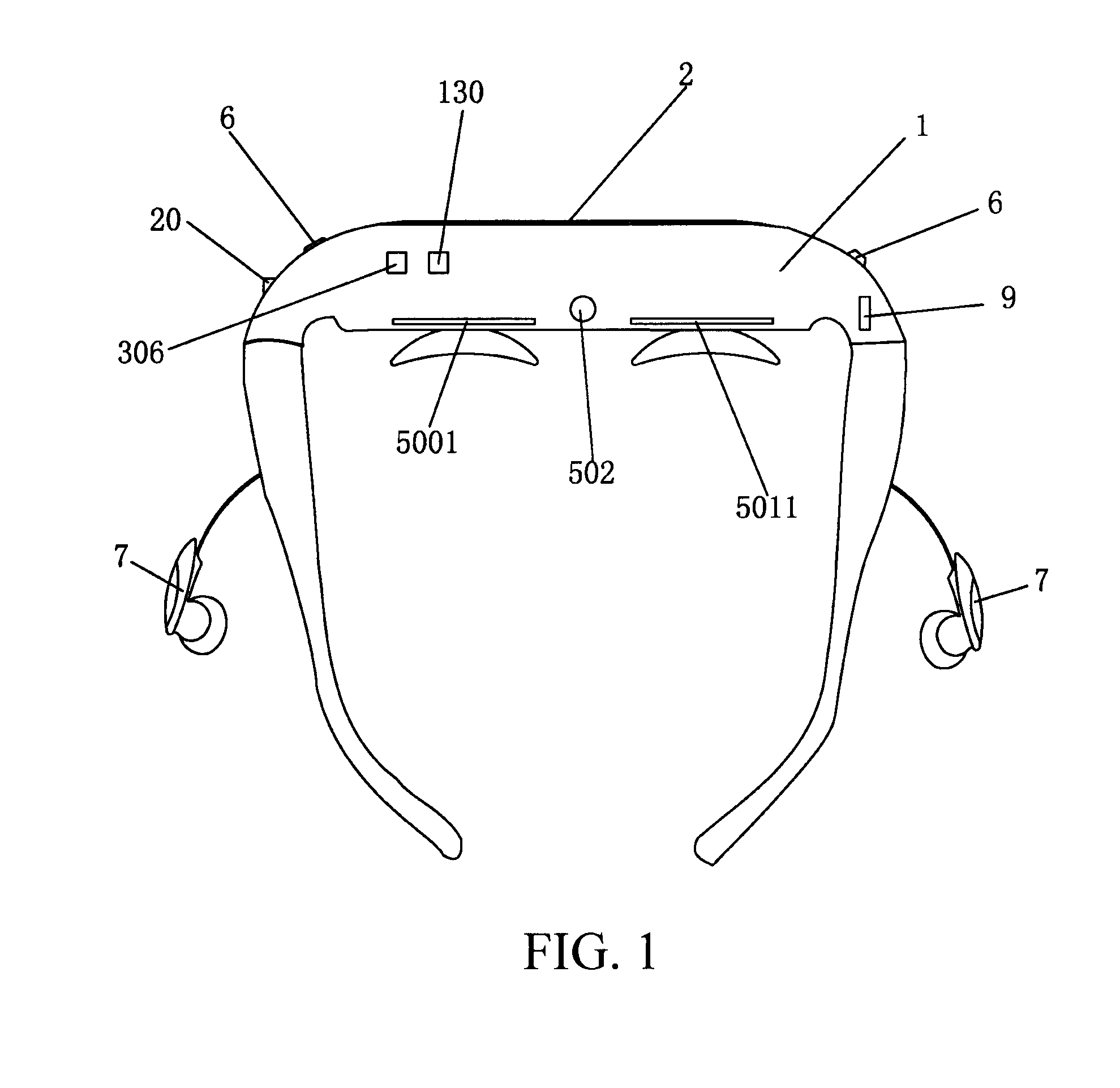

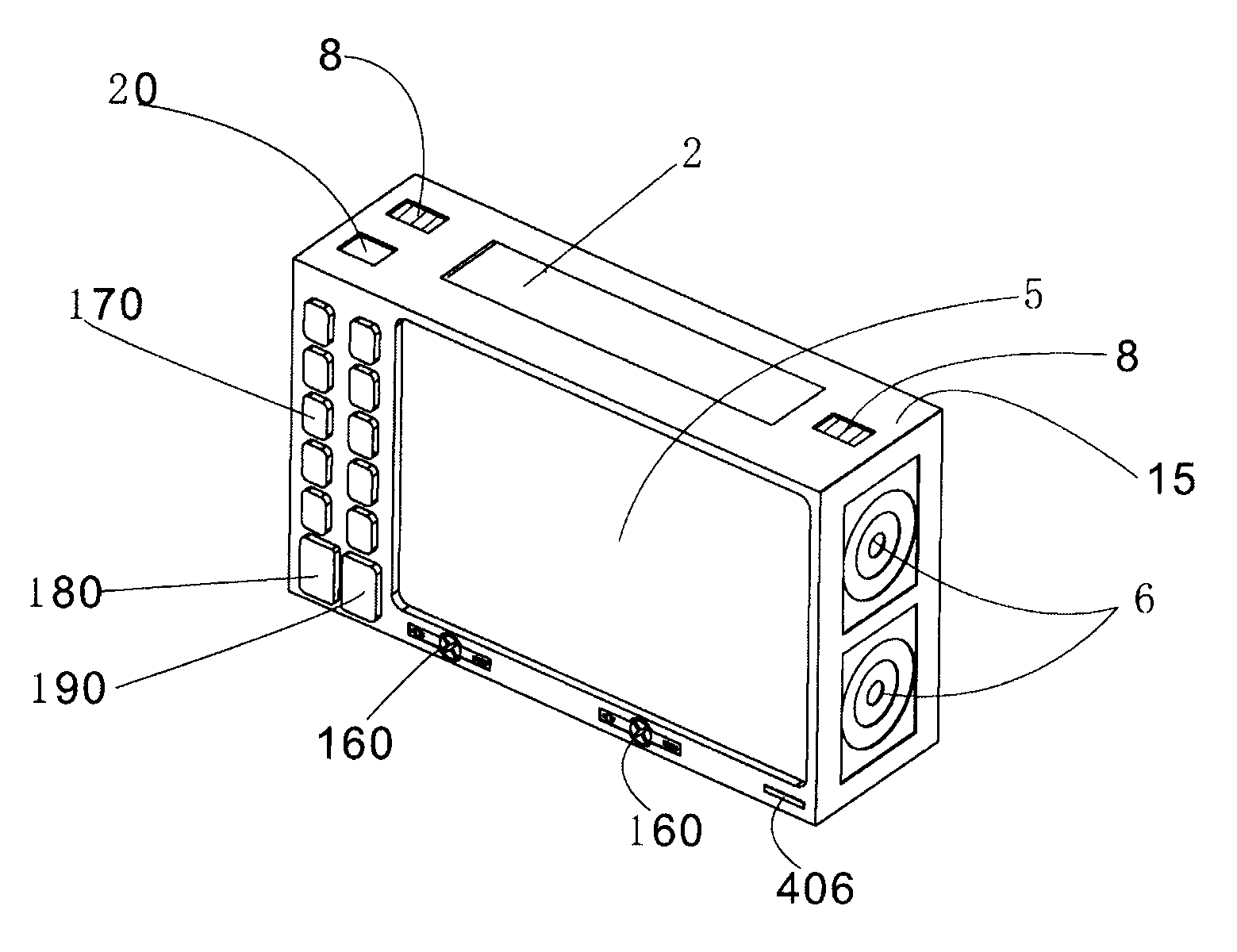

Integrative spectacle-shaped stereoscopic video multimedia device

ActiveUS8259159B2Simple structureLow costSteroscopic systemsStereoscopic videoComputer graphics (images)

Owner:INLIFE HANDNET CO LTD

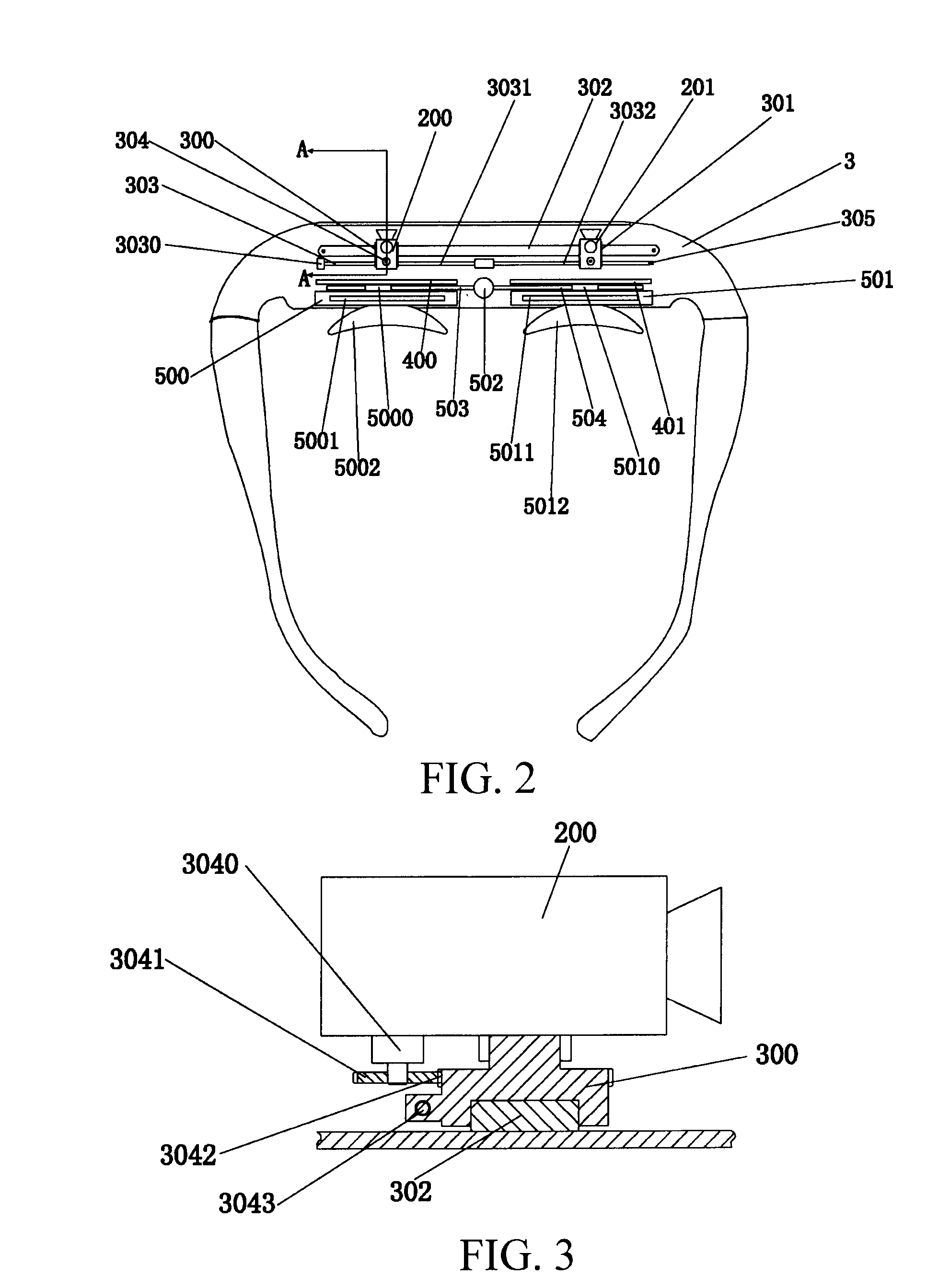

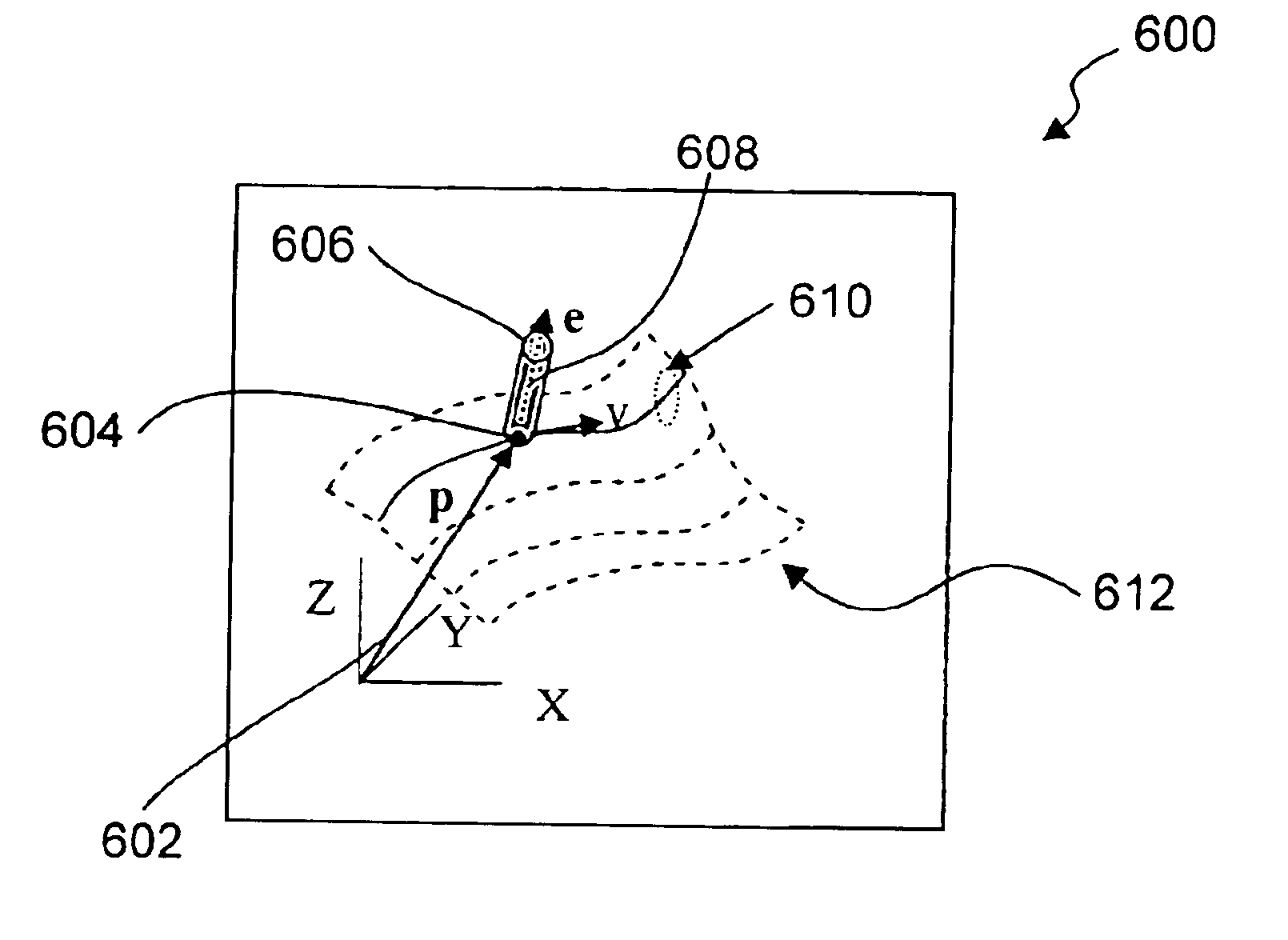

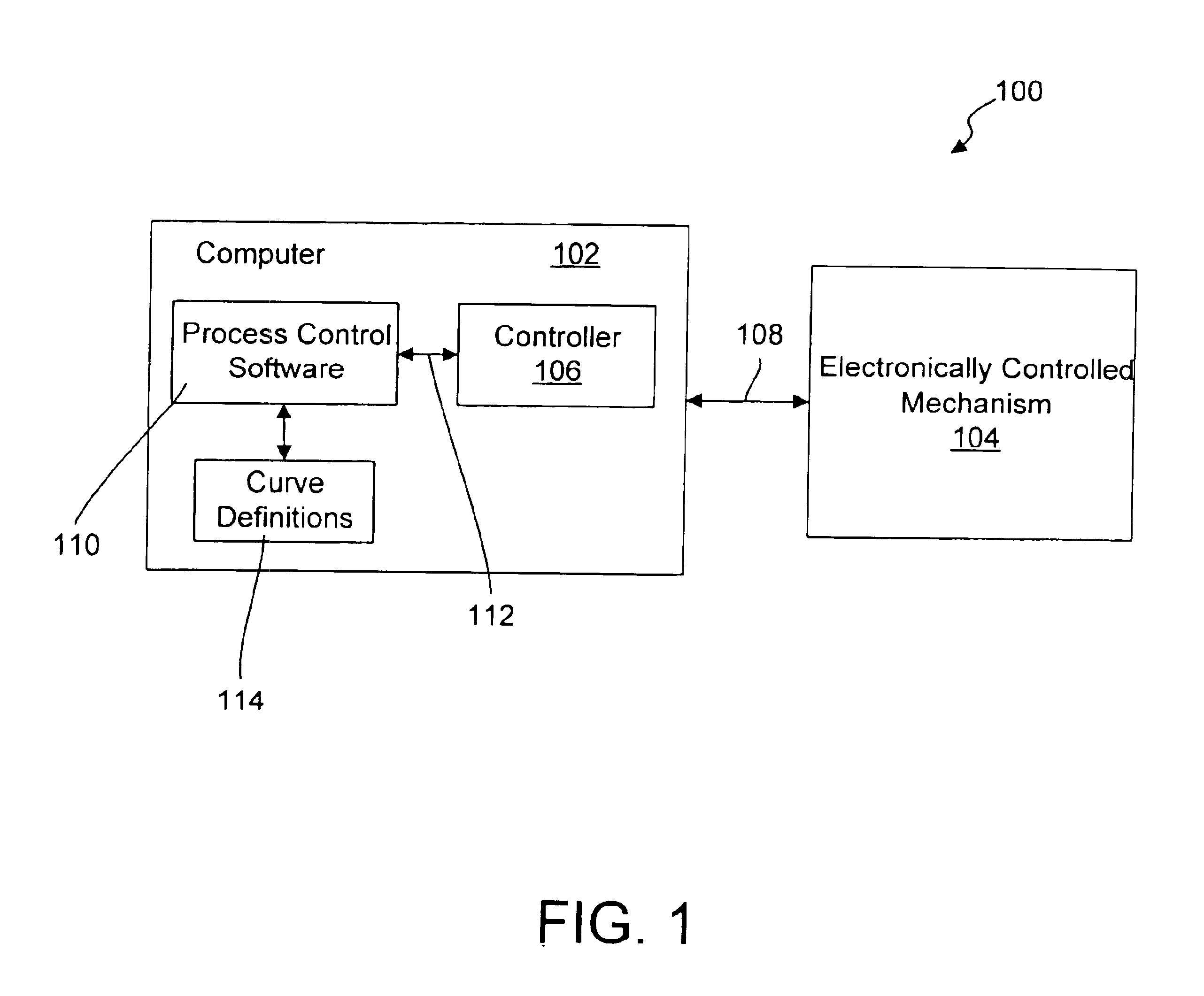

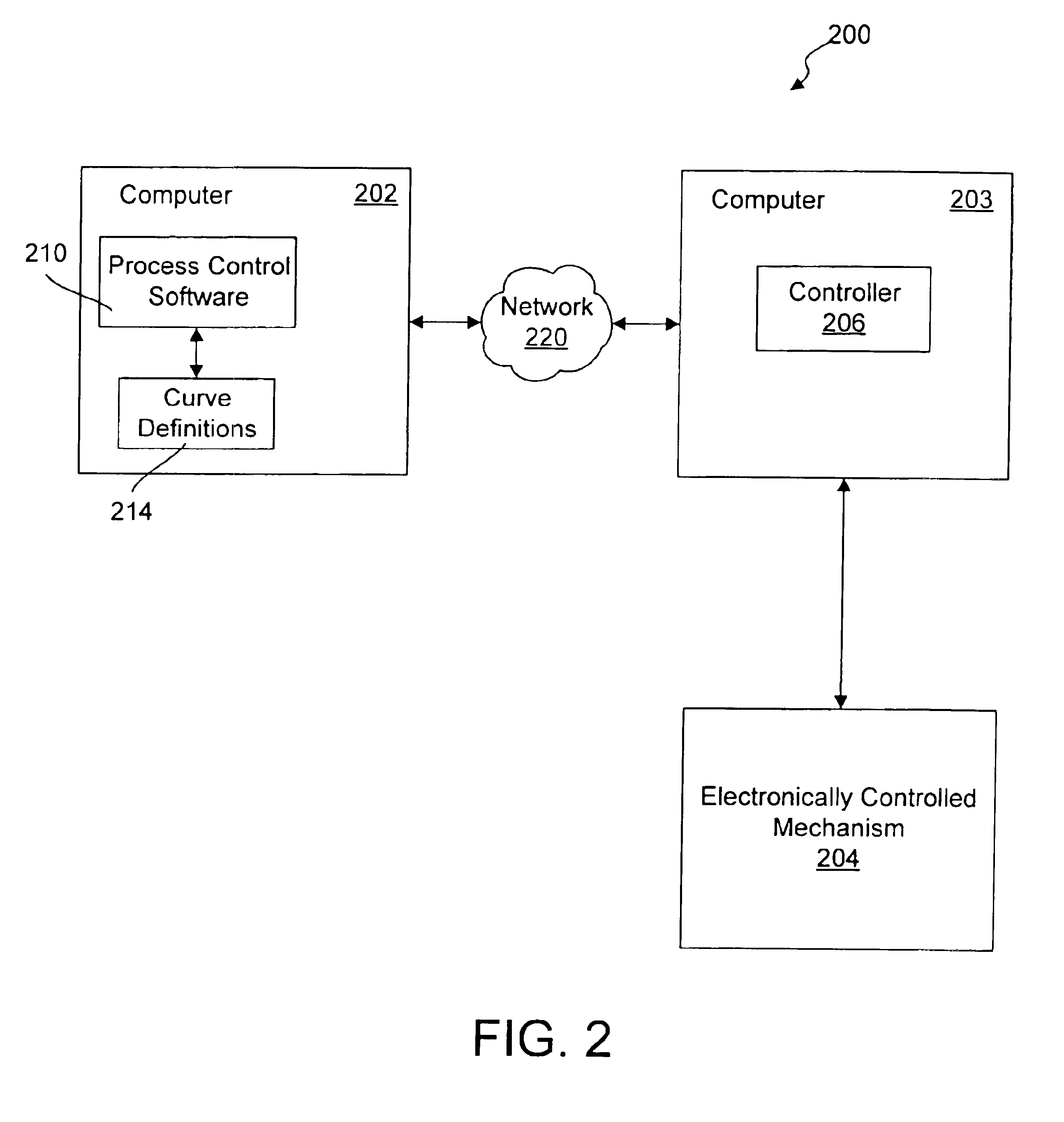

Systems and methods for representing complex n-curves for direct control of tool motion

InactiveUS6895299B2Computer controlSimulator controlElectronic communicationProcess control software

A method for controlling a mechanism through the use of higher-dimensional n-curves is disclosed. An electronically-controlled mechanism is provided. Electronic communication is established between a computer and the electronically-controlled mechanism. A controller is running or executing on the computer to send mechanism commands to the electronically-controlled mechanism. Process control software is used to control the electronically-controlled mechanism. The process control software uses higher-dimensional n-curves to control the electronically-controlled mechanism.

Owner:BRIGHAM YOUNG UNIV

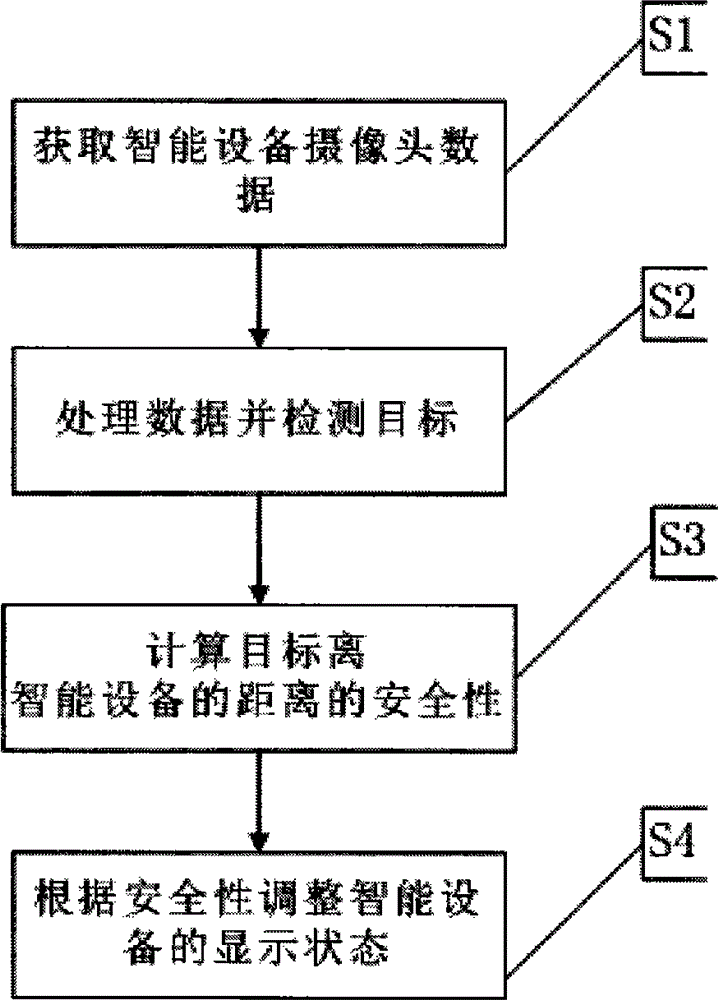

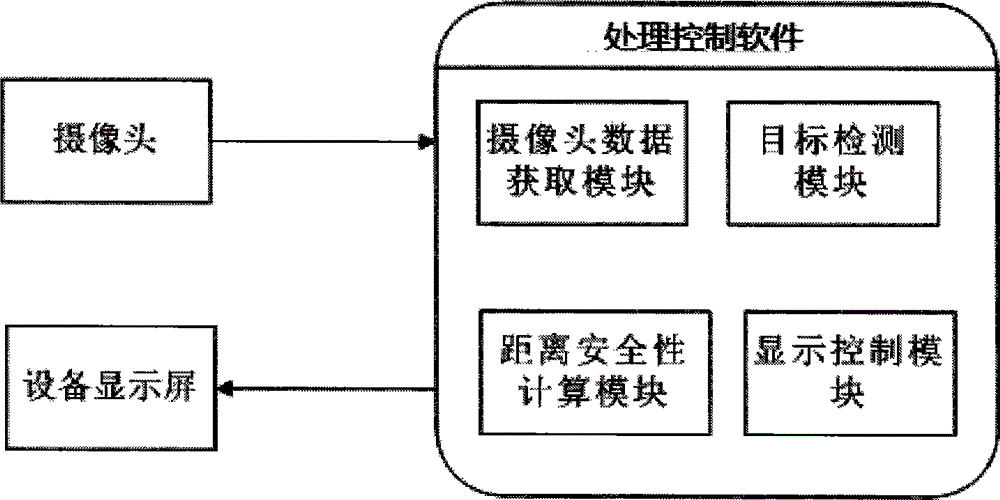

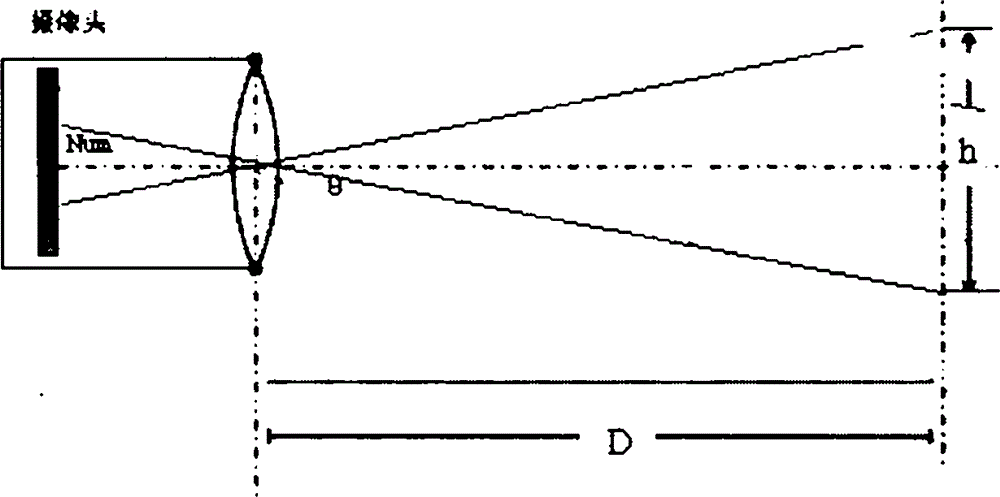

Eyesight protecting method and system for smart device

InactiveCN104090656ALow costRich in processing powerInput/output for user-computer interactionCharacter and pattern recognitionData acquisitionProcess control software

The invention discloses an eyesight protecting method for a smart device. The method includes: continuously or discontinuously acquiring the data of the camera of the smart device, processing the data of the camera and detecting a target, calculating the safety (whether the distance is safe or not or data indicting safety degree) of the distance between the target and the smart device, and adjusting the display state of the smart device according to the safety of the distance. An eyesight protecting for the smart device uses processing control software as a core to process the data of the camera of the smart device and controls the display state of the smart device. The processing control software comprises a camera data acquisition module, a target detecting module, a distance safety calculating module and a display control module.

Owner:潘晓丰

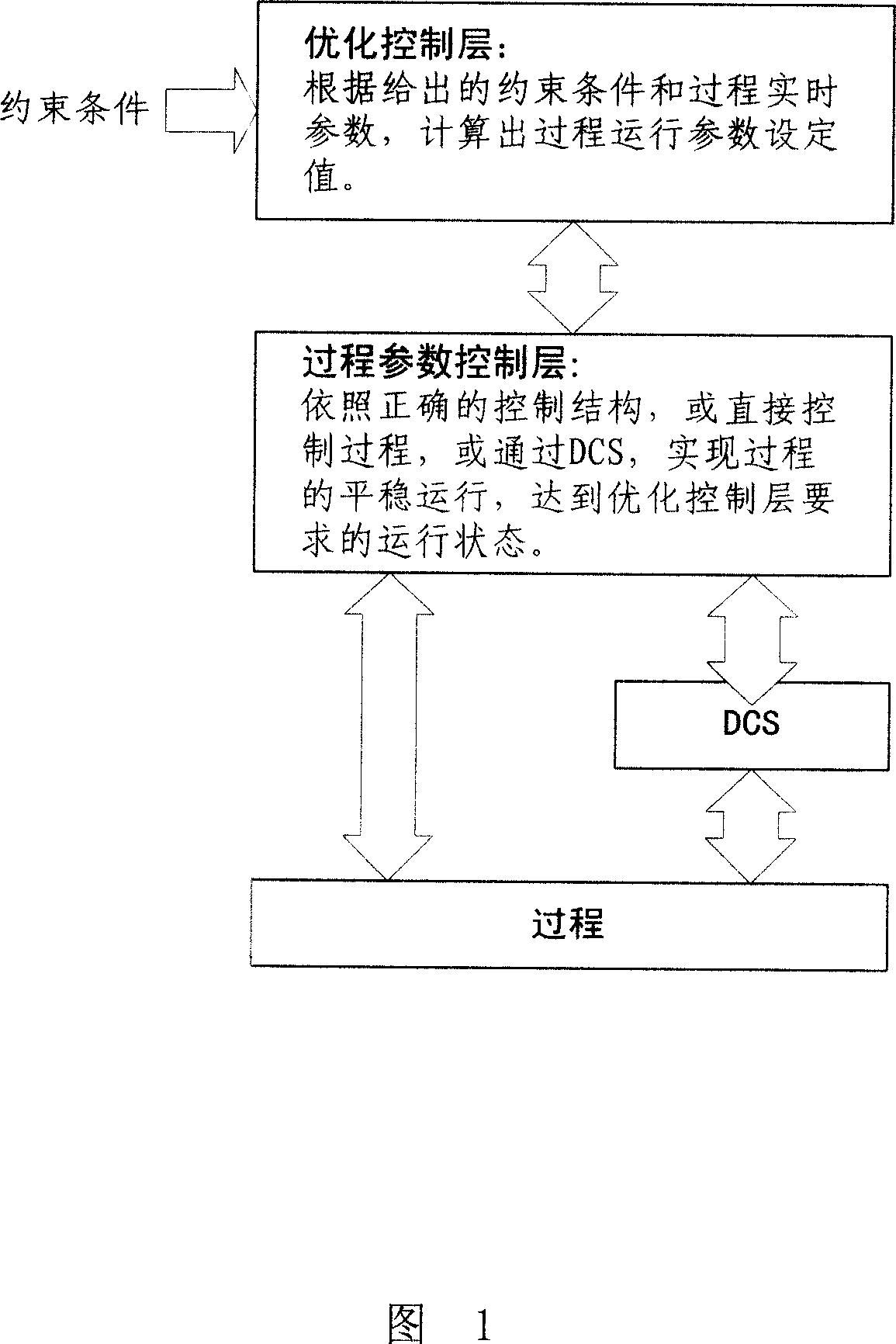

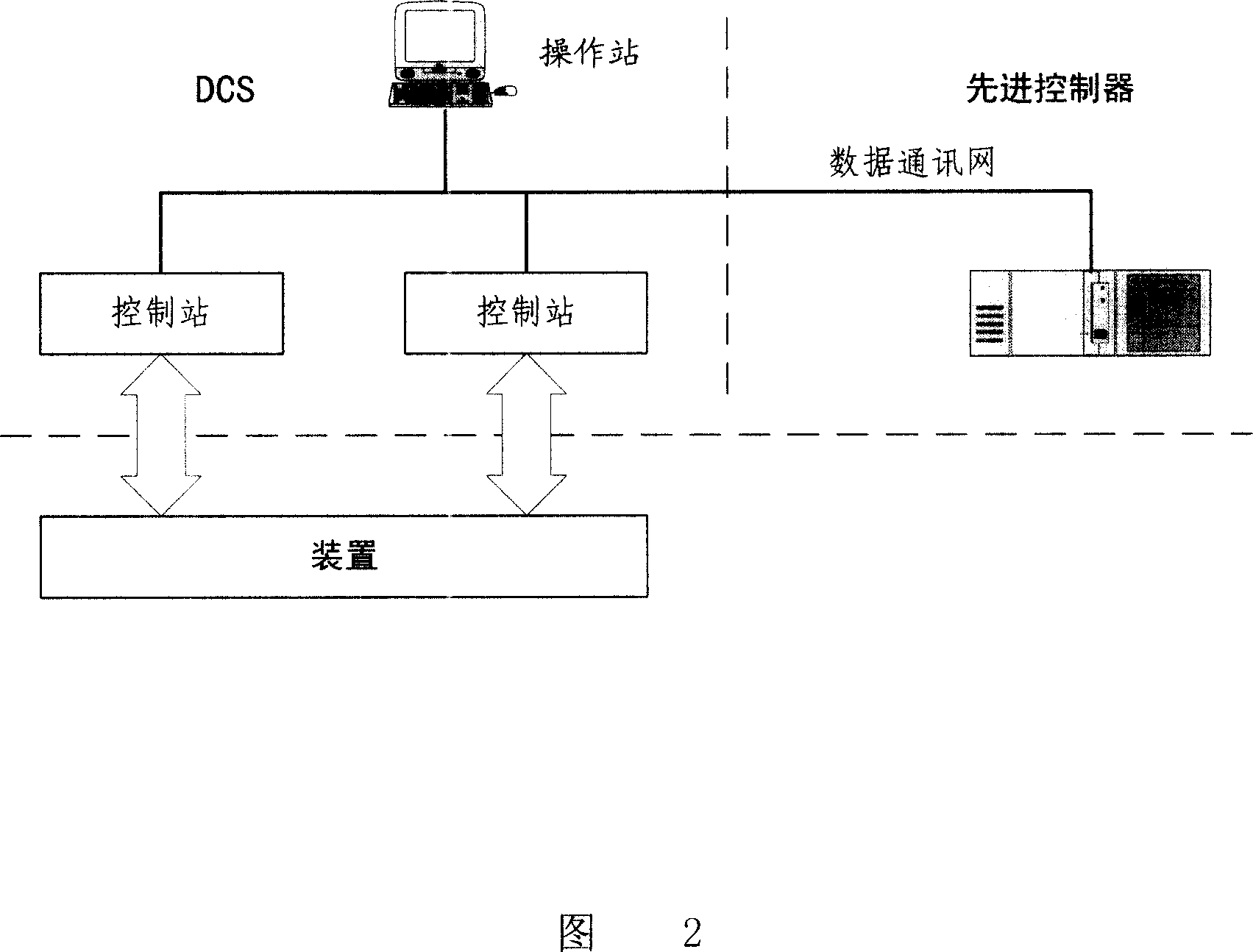

High robust advanced control method and control system thereof

InactiveCN101135887ARealize simulationReduce performanceTotal factory controlAdaptive controlHuman–machine interfaceControl engineering

The method is used for improving the bad robustness when a normal manufacturing process in petrochemical industry and pharmacy industry is taken as a controlled object. It comprises: 1) establishing a advanced process-controlling software frame; 2) establishing the advanced process-controlling software frame core; 3) establish a human-machine interface of the advanced process-controlling frame; 4) establishing an advanced process-controlling software simulation pack to simulate each type of the controlled object. Said control system comprises an operation station, a advanced controller, a control station and a data communication network.

Owner:大庆开发区华创电子有限公司

High speed and repeatability serial sectioning device for 3-D reconstruction of microstructures

InactiveUS7319915B1Increase speedImprove accuracyWithdrawing sample devicesPreparing sample for investigationReal time analysisDigital imaging

A high speed, high precision, high repeatability serial sectioning device and method for 3-D reconstruction of microstructure specimens. The invention employs a high-precision motorized metallographic polishing unit, a microscope for viewing and computer controlled digital imaging of 2-D microstructure sections of a pre-selected pattern for 3-D microstructure reconstruction. The microstructure specimens are transferred throughout by a robotic manipulator arm providing greater precision and speed and serial-sectioning process control software provides control. The 3-D reconstruction of the invention can be analyzed in real time and can be accomplished in a matter of hours.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Method for assisting production of woodwork furniture by using RFID chips

InactiveCN105171880AMake an impactIncrease productivityComputer controlWood working apparatusComputer-aidedComputer aid

The invention discloses a method for assisting production of woodwork furniture by using RFID chips. The method comprises the following steps: firstly modeling the furniture according to a ratio of 1 to 1 through computer-aided designing and manufacturing software of woodwork, in wherein each plate of the furniture in the model has own unique identification code; synchronously printing a label of each plate by equipment during cutting in a production workshop, marking the identification code of the plate on the label, then forming holes in the plates by using gang drill equipment or forming slots in the plates through manners such as sawing and milling in the next process, putting carriers with RFID labels into the holes or the slots, putting a suspension sensor at a feeding end of each process, automatically reading RFID identification codes when the plates pass through the suspension sensors, reading corresponding data and drawings generated by WCC by using production process control software, and assisting manual production. The method is applicable to various complex production environments; the influence on the chips caused by hot pressing, sanding and spraying paint can be avoided.

Owner:陈文杰

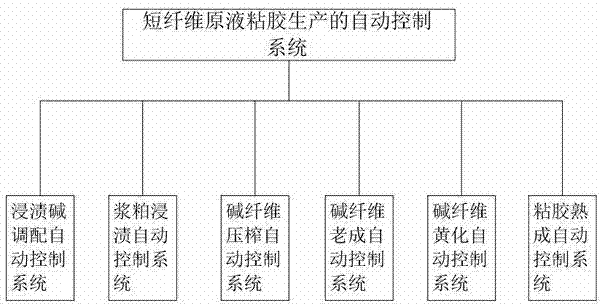

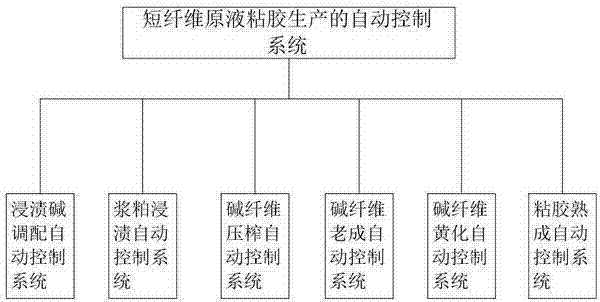

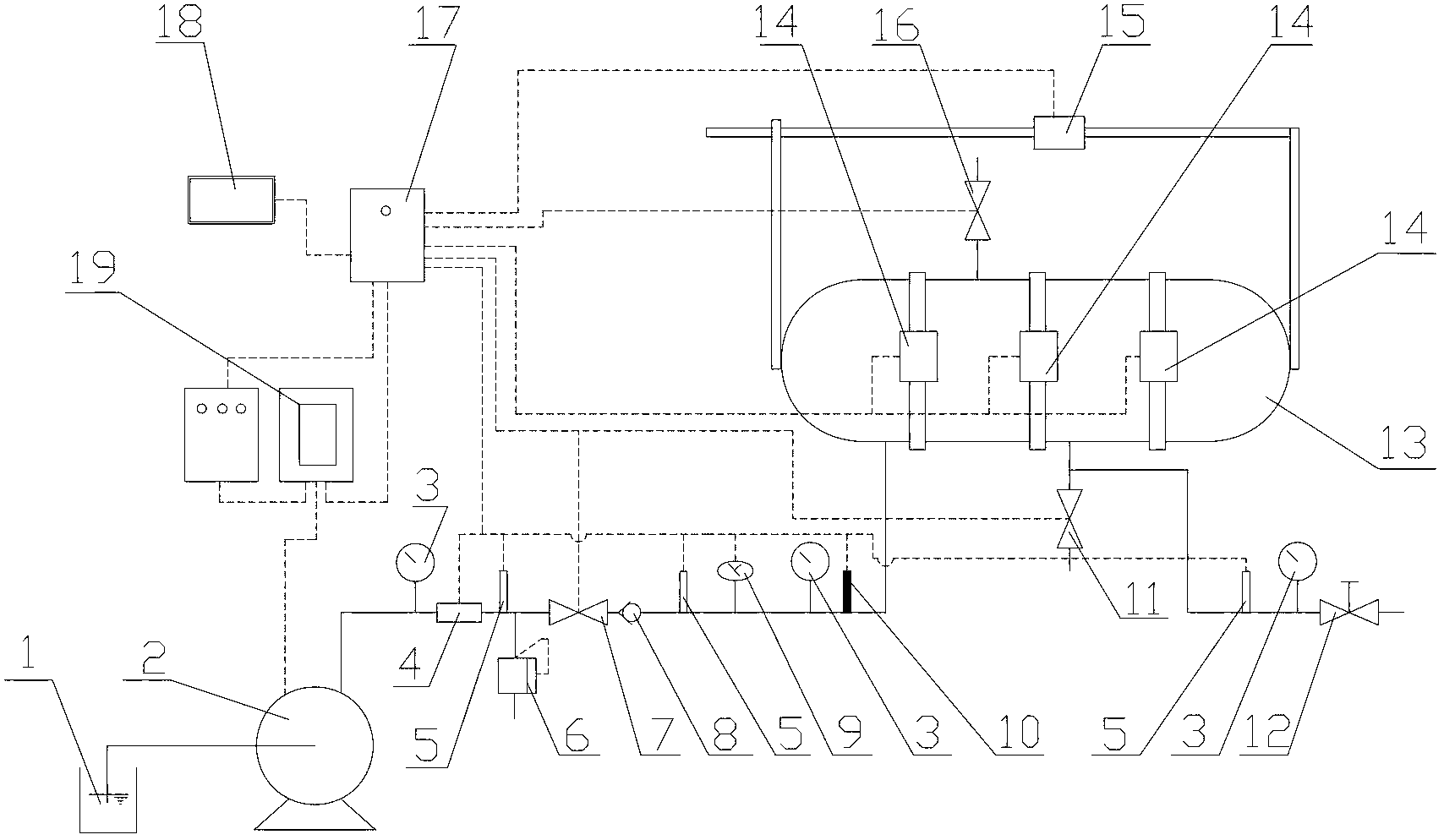

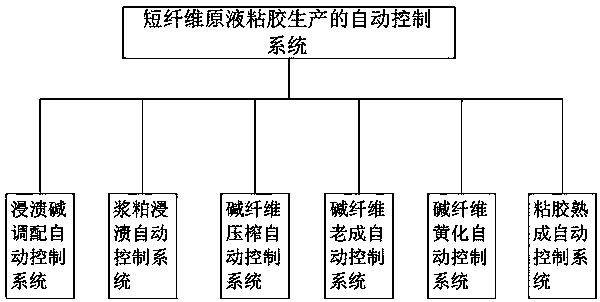

Automatic control system in production of short fiber stock solution viscose

ActiveCN102393691AReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system design

The invention provides an automatic control system in production of short fiber stock solution viscose, belongs to the field of artificial fibers, and aims to solve the problems that a distributed control system (DCS) cannot comprehensively control the production of the short fiber stock solution viscose as a whole and control operation is complicated in the prior art. A redundant process control system is constructed by redundant process control software, so that an impregnation alkali blending automatic control system, a pulp impregnation automatic control system, an alkaline fiber pressing automatic control system, an alkaline fiber automatic ageing control system, an alkaline fiber yellowing automatic control system and a viscose ripening automatic control system are established to automatically control each link in the production, the long-period continuous operation of the whole production process is ensured, and the process cannot be influenced due to the failure of the automatic control system; and the control system is reasonable in design and simple in control steps, and manual labor is greatly reduced.

Owner:YIBIN HIEST FIBER +1

Various methods and apparatuses to provide remote access to a wind turbine generator system

Various methods and apparatus are described for providing remote access to a wind turbine generator system in which a power management controller (104) with process control software controls output power characteristics of a group of wind turbine generators (102). The power management controller (104) also has a network interface configured to allow a user of a monitoring and control network (108) to remotely access and change the The output power setting of the set of wind turbine generators (102).

Owner:GENERAL ELECTRIC RENOVABLES ESPANA SL

High speed and repeatability serial sectioning method for 3-D reconstruction of microstructures using optical microscopy

InactiveUS7319916B1Increase speedImprove accuracyWithdrawing sample devicesPreparing sample for investigationReal time analysisDigital imaging

A high speed, high precision, high repeatability serial sectioning method for 3-D reconstruction of microstructure specimen is disclosed. The invention employs high-precision motorized metallographic polishing, viewing and computer controlled digital imaging of microstructure sections of a pre-selected pattern for 3-D microstructure reconstruction. The microstructure specimens are transferred throughout by a robotic manipulator arm, which provides greater precision and speed and serial-sectioning process control software provides control. The 3-D reconstruction of the invention can be analyzed in real time and can be accomplished in a matter of hours.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Portable integrative stereoscopic video multimedia device

InactiveUS20100177167A1Simple structureVivid stereoscopic effectColor television detailsClosed circuit television systemsStereoscopic videoDisplay device

A portable integrative stereoscopic video multimedia device includes two digital camera modules, an adjusting device for adjusting an axle distance and included angle between the digital camera modules, a naked eye stereoscopic image liquid crystal display, optical projection systems, a projection control and image signal driver, sound pickups, loudspeakers, a memory, signal interfaces, a plurality of analog / digital converters, 2D / 3D signal converters, a processor, a power source, process control software, and a body. Through the invention, a user may view stereoscopic images on the display or projected plane images with naked eyes. The invention has advantages of a simple structure and a vivid stereoscopic effect of the shot and viewed images. After further modification, the invention may be used for shooting, storing, and playing images, and may form a multi-functional personal electronic device with a mobile communication unit, an entertainment unit, and a projection unit.

Owner:INLIFE HANDNET CO LTD

High speed and repeatability serial sectioning method for 3-D reconstruction of microstructures using scanning electron microscope

InactiveUS7319914B1Increase speedImprove accuracyWithdrawing sample devicesPreparing sample for investigationDigital imagingReal time analysis

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

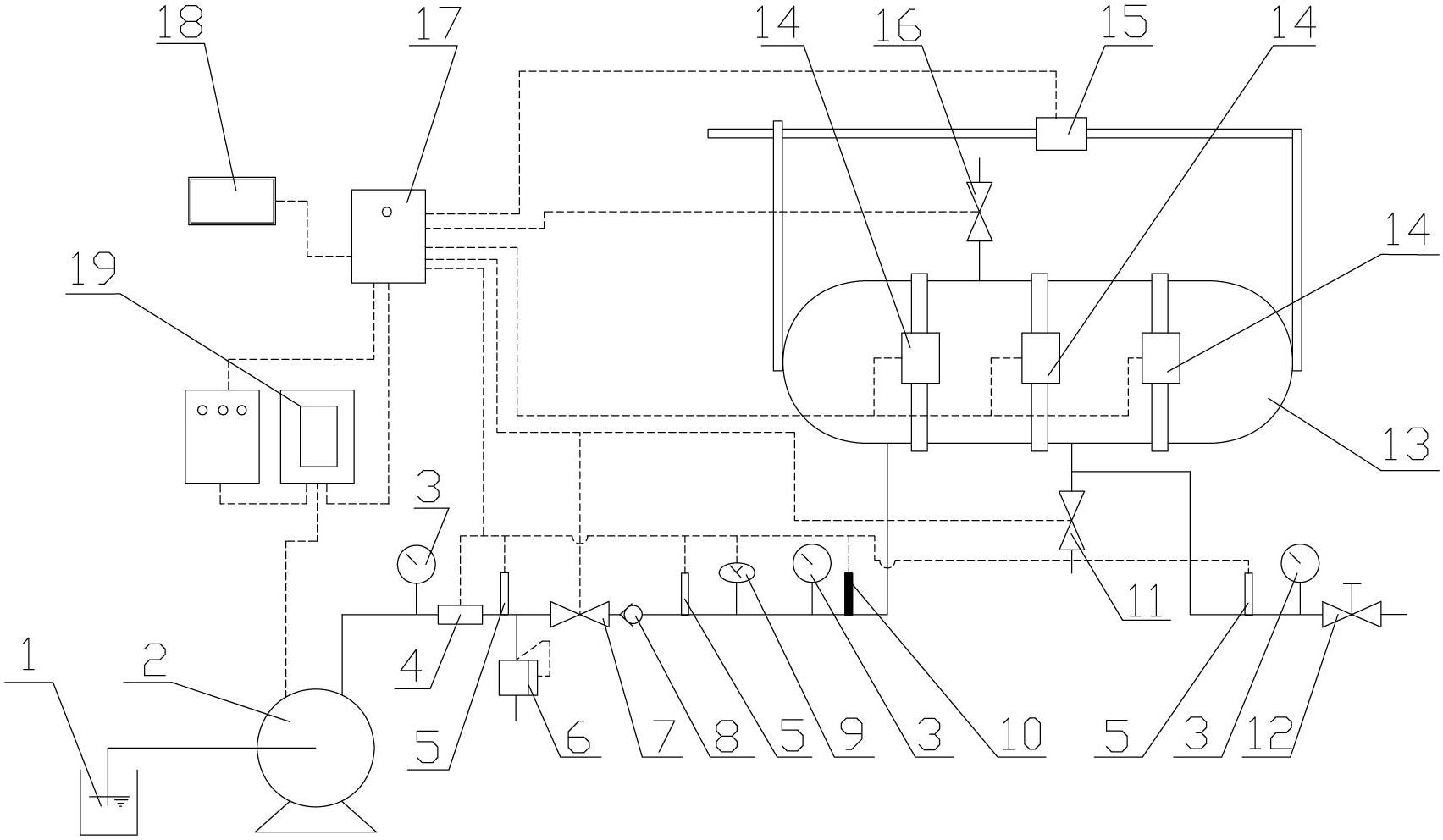

Strain strengthening pressure device and pressure method for austenitic stainless steel low-temperature vessel

The invention discloses a strain strengthening pressure device and pressure method for an austenitic stainless steel low-temperature vessel. The strain strengthening pressure device for the austenitic stainless steel low-temperature vessel comprises a pressure device, deformation sensors, a frequency changer, a measurement and control signal processor and a computer, wherein the deformation sensors are loaded on a to-be-processed vessel. The strain strengthening pressure method for the austenitic stainless steel low-temperature vessel comprises the following steps of: delivering pressure into the to-be-processed vessel by the pressure device; transmitting deformation signals detected by the deformation sensors to the measurement and control signal processor for processing; then, transmitting to the computer; comparing acquired signals by the computer according to processing control software; then, sending out control signals; respectively controlling the frequency changer and a switch of an electric check valve through the measurement and control signal processor; performing a pressure operation and a pressure maintaining operation by controlling the pressure device through the frequency changer; and performing a pressure-relief operation through opening the pressure-relief electric check valve. According to the strain strengthening pressure device for the austenitic stainless steel low-temperature vessel, the deformations of multiple parts are monitored by adopting the circumference and axial length sensors, so that 1-10 percent of plastic deformation can be generated by the to-be-processed vessel according to the process requirement, and the goal of strain strengthening is achieved.

Owner:SOUTH CHINA UNIV OF TECH

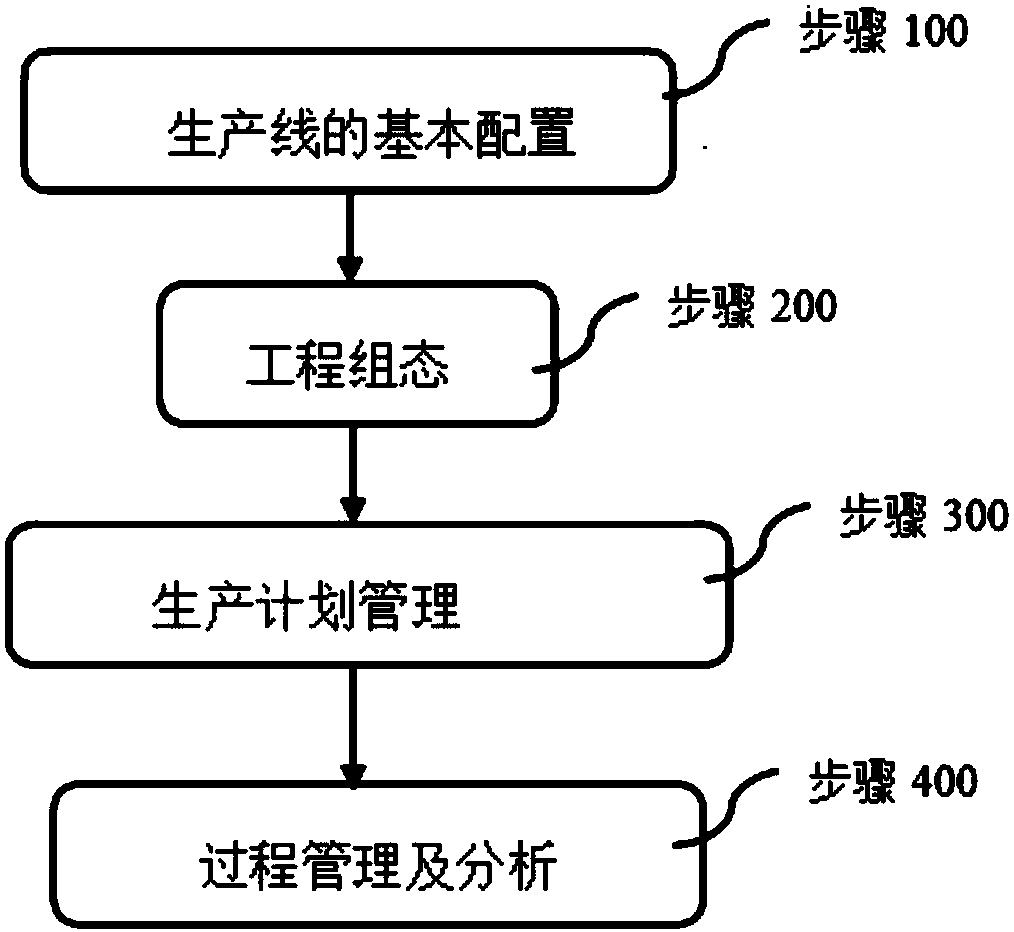

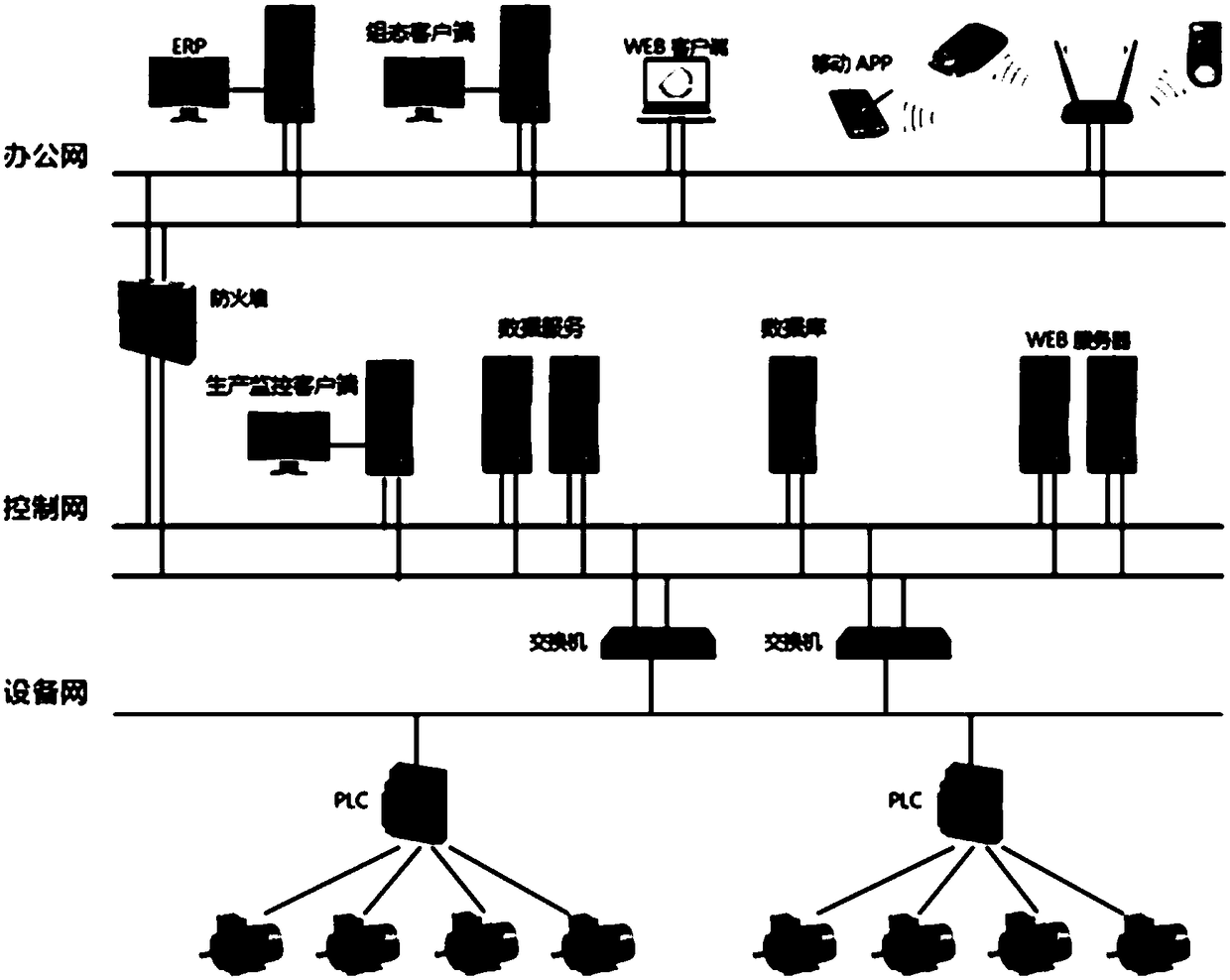

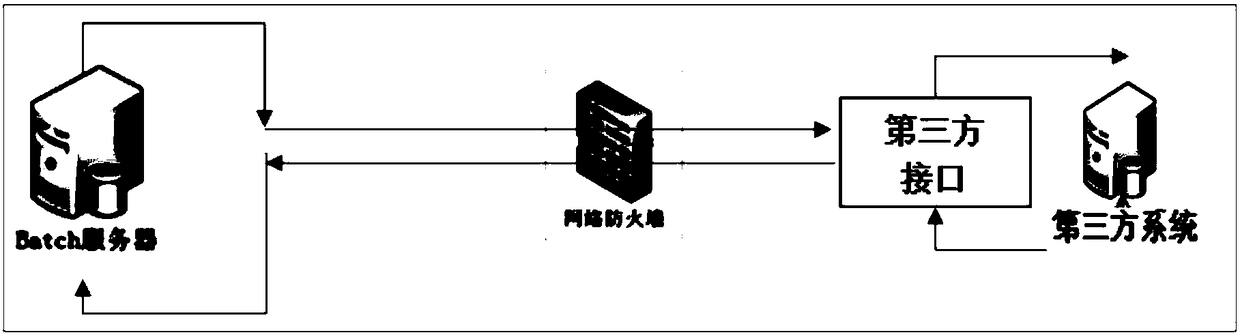

Batch food-medicine production method based on SCADA (Supervisory Control and Data Acquisition) and software system

InactiveCN108229833AIncrease profitImprove efficiencyResourcesManufacturing computing systemsPersonalizationSoftware system

The invention discloses a batch food-medicine production method based on SCADA (Supervisory Control and Data Acquisition) and a software system. The batch food-medicine production method comprises thesteps of basic configuration of a production line, engineering configuration, production planning management and process management and analysis; the software system comprises a configuration client,a production scheduling client and a data server, and is a process control software which is suitable for performing alternatively in a continuous process and a discrete process and is obvious in batch and strong in intermittence, is suitable for industries of food, pharmacy and the like; control formula configuration is supported, a set of formula can be produced through a plurality of production equipment paths; the equipment utilization rate is increased; in the same control formula, different raw material comparison schemes can be set in order to meet the production requirements of a plurality of products, personal requirements of different products can be met, high monitoring function is achieved, multi-level user management is supported, the electronic signature is safe, and the production process is reliable, safe and is high in efficiency, and the product is stable in quality.

Owner:和利时卡优倍科技有限公司 +1

Yellowing automatic control system in production of short fiber stock solution viscose

ActiveCN102393694AReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention provides a yellowing automatic control system in production of short fiber stock solution viscose. The conventional automatic control system is improved and optimized, and a redundant process control system is constructed by redundant process control software, so that the yellowing automatic control system in the production of the short fiber stock solution viscose is established. The system comprises a control unit, an alkaline fiber feeding control unit, a vacuum degree control unit, a CS2 feeding control unit, a yellowing reaction control unit, a dissolved alkali feeding control unit, a viscose discharging control unit and a yellowing machine washing control unit in turn. The control system can accurately control the addition amount of each material, ensures the quality of the finally yellowed viscose, reduces manual labor, saves cost, and improves production efficiency.

Owner:YIBIN HIEST FIBER +1

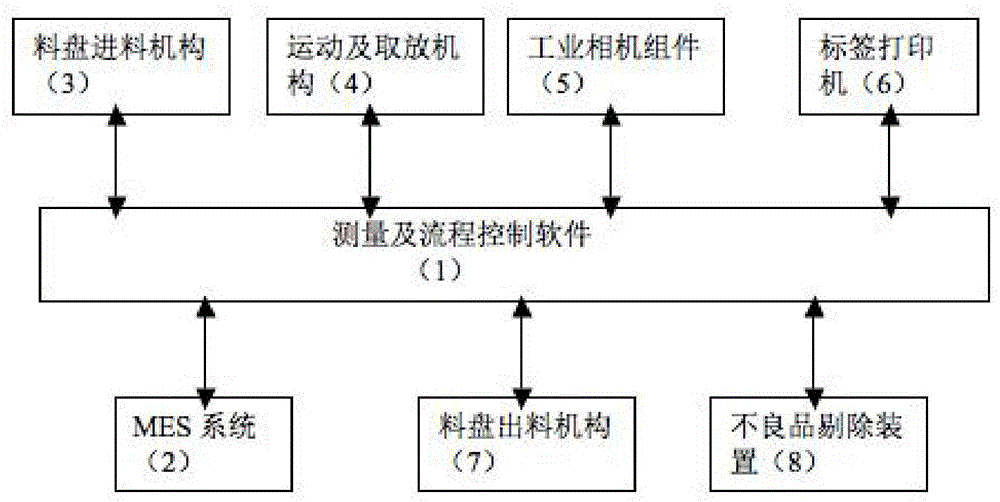

Equipment for full-automatically and rapidly checking residual materials in SMD material trays

PendingCN106779041ASolve efficiency problemsSolve the costCounting objects on conveyorsProcess control softwareLabelling

The invention discloses equipment for full-automatically and rapidly checking residual materials in SMD material trays. The equipment comprises measurement and process control software, an MES system, a material tray feeding mechanism, a movement and pick-place mechanism, an industrial camera component, a label printer, a material tray discharging mechanism, defective product rejection device, a material tray feeding station, a measurement station, a labelling station and a discharging station, wherein the material tray feeding mechanism, the movement and pick-place mechanism, the industrial camera component, the label printer, the material tray discharging mechanism and the defective product rejection device are respectively connected with the measurement and process control software through signal lines. According to the equipment disclosed by the invention, the specification information and size information of a material tray are obtained by the industrial camera component through shooting, specific data is obtained through image measurement and analysis, and the quantity of residual materials is calculated through a residual material calculation formula. The method is rapid and correct, and is capable of effectively solving the problem that the existing manual material checking method and method for carrying out material checking through manual SMD material checking machines are low in efficiency and high in labor cost.

Owner:XIAMEN FO CO NETWORK TECH

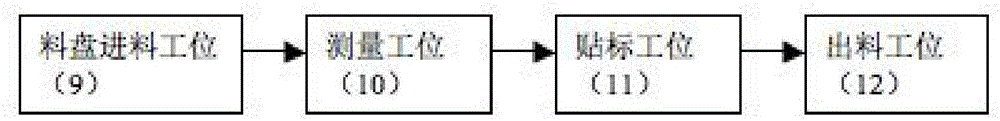

Method of realizing automatic block clearing and continuous operation of up flow type ash cabin pump

InactiveCN1824593ARealize continuous operationGas phase concentration adjustmentLarge containersBulk conveyorsEngineeringProcess control software

The present invention relates to a method for making up-going lime bin pump implement automatic blockage elimination and its continuous operation. Said method is implemented by utilizing existent lime bin pump system, central processor in control circuit and process control software stored in EEPROM. It is characterized by that between main lime-conveying pipe and lime-stored tank a lime-discharging pipe and a controlled lime-discharging valve are set. Besides, it also includes the components of air inlet tube, etc. Said invention also provides the concrete steps for implement said method.

Owner:李玉清

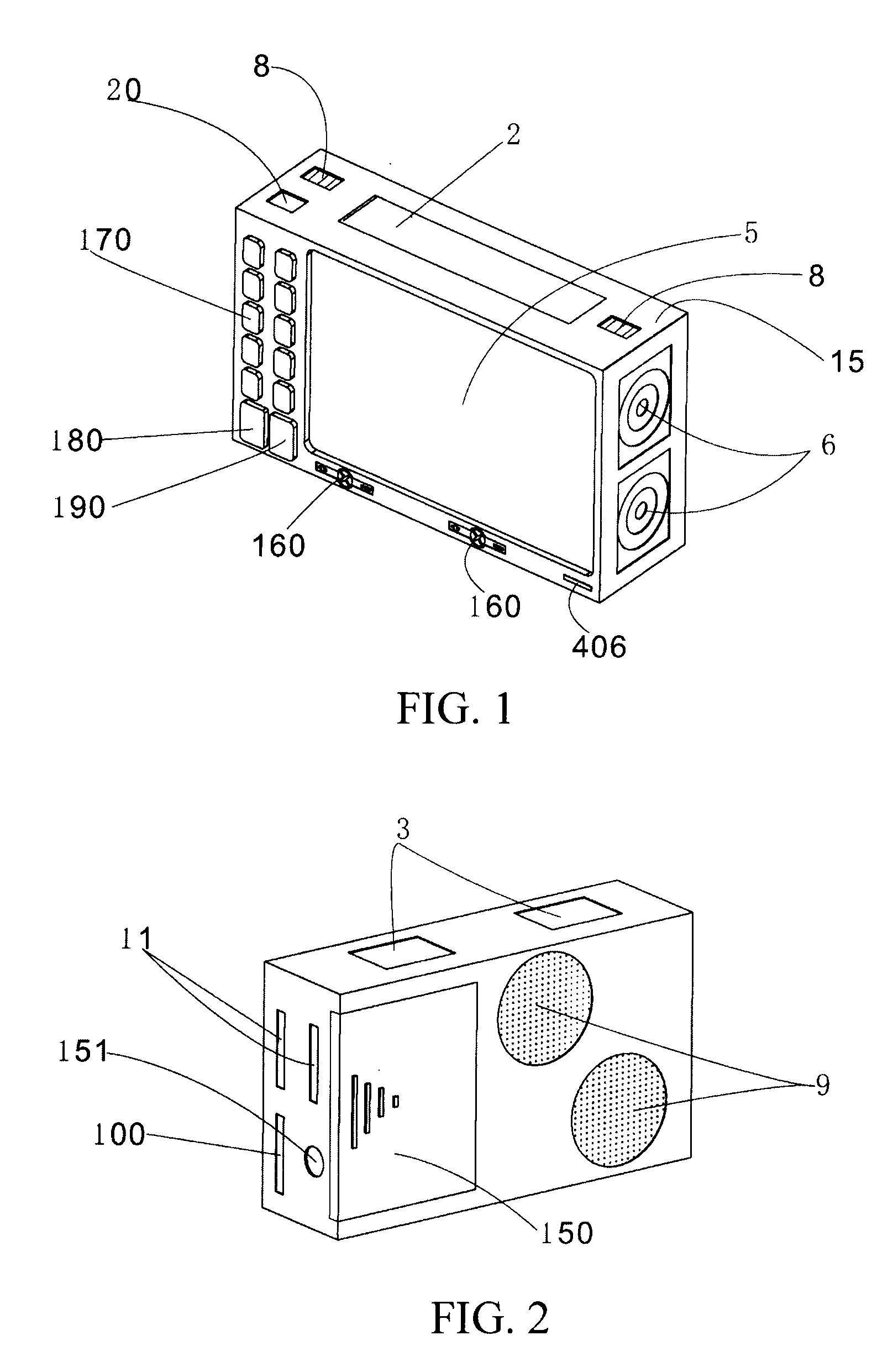

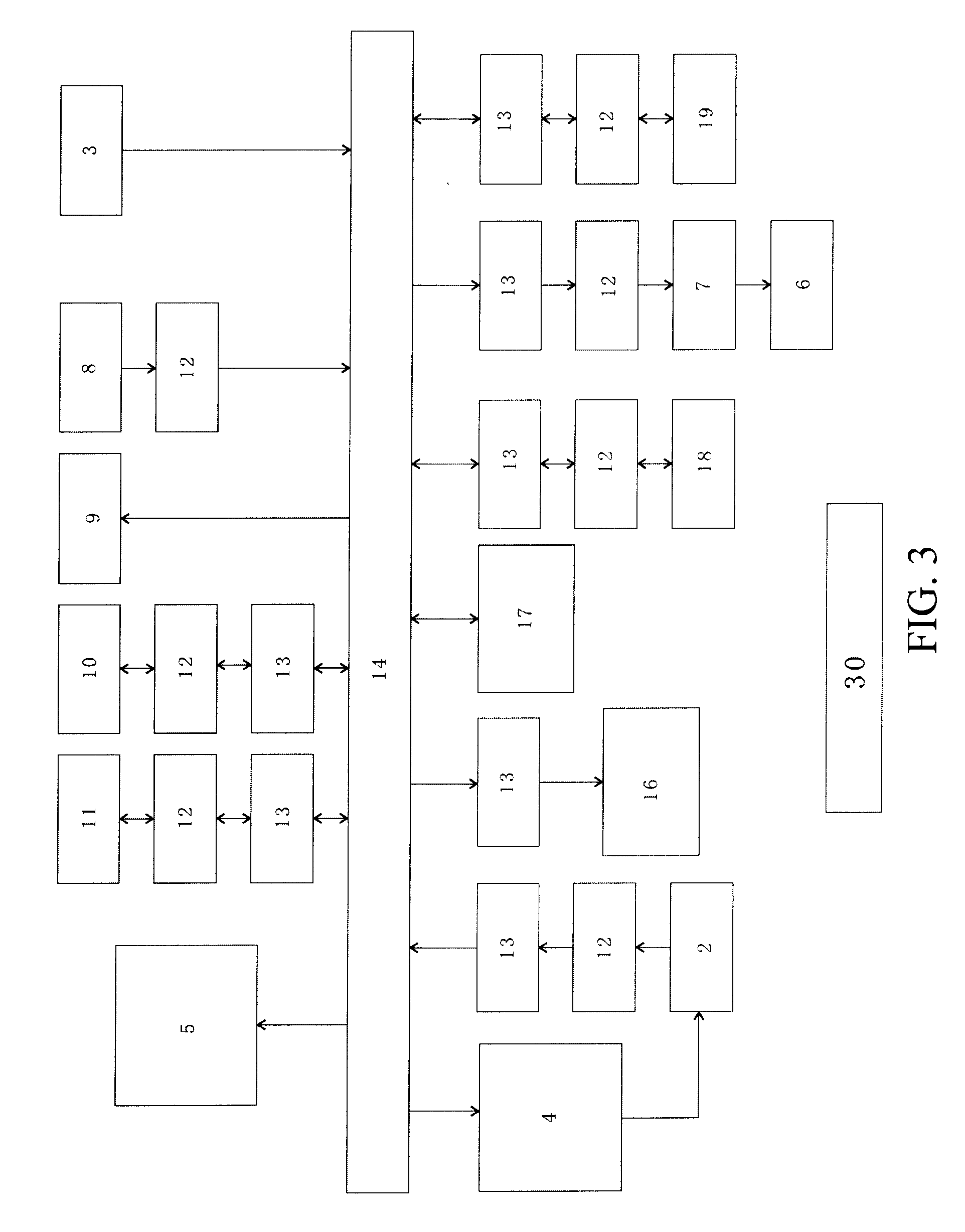

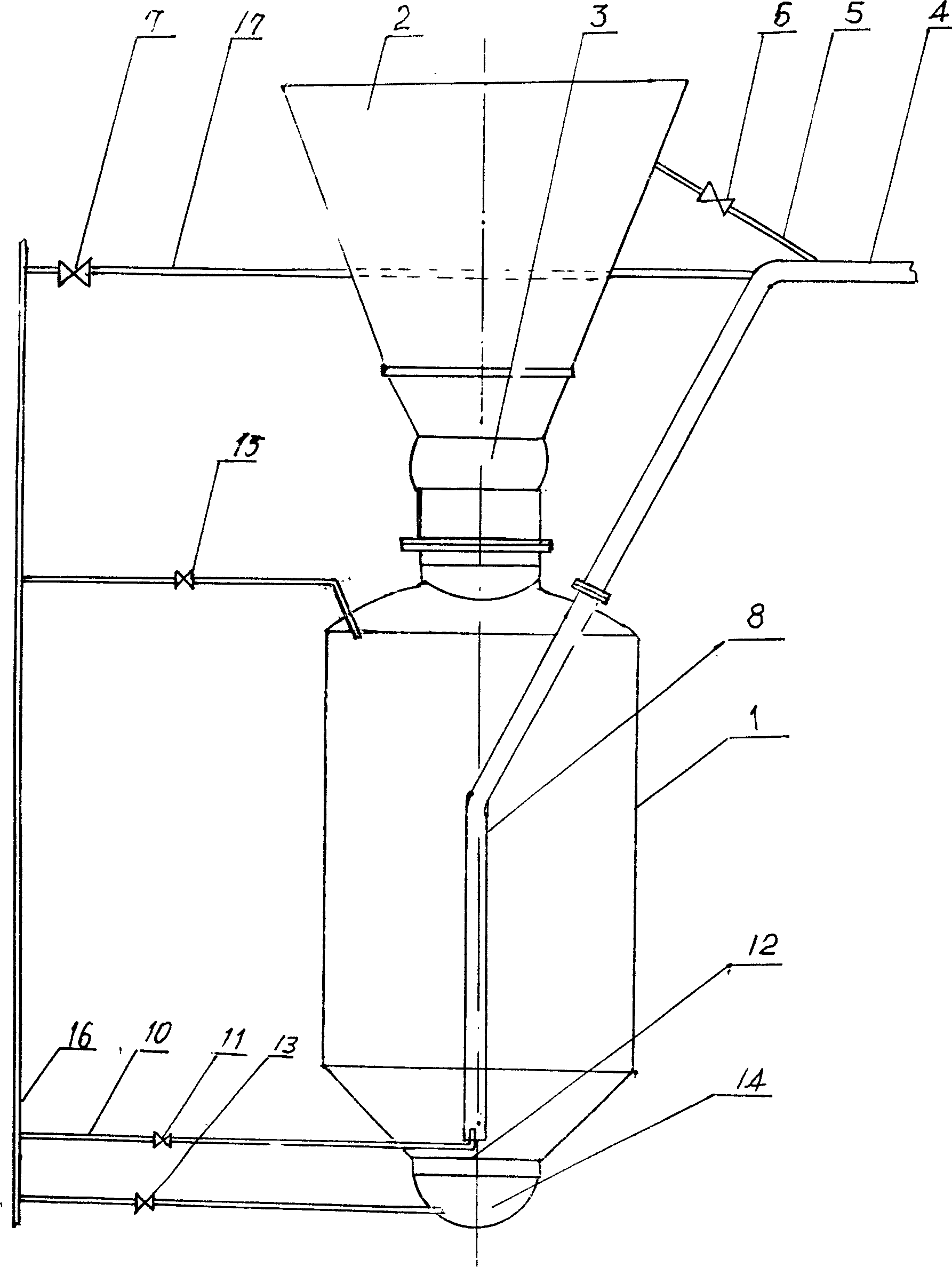

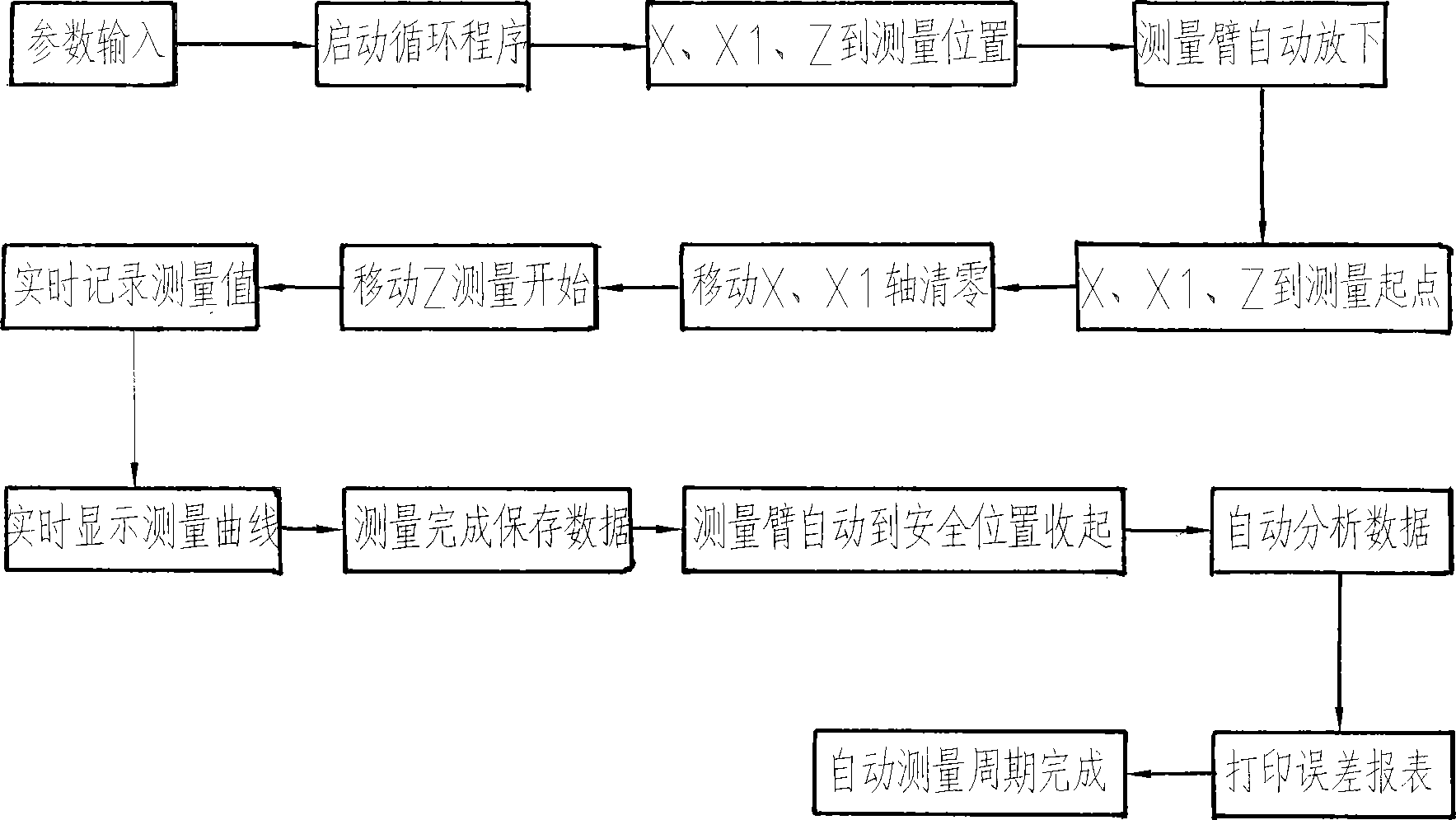

Automatic detection apparatus and control method for roll grinder

InactiveCN101464677AImprove work efficiencyReduce labor intensityProgramme controlComputer controlHuman–machine interfaceMeasurement device

The invention mainly relates to the technical field of the control of a roll shaped measuring device used for a roll grinder, particularly to a roll grinder automatic detecting device and the control method thereof. The automatic detecting device comprises a man-machine interface (1); the man-machine interface (1) is connected with a control system (2) through a PROFBUS communication bus; the automatic detecting device further has the characteristics that the control system (2) is connected with a servo module (3) through a data bus; the control system (2) is connected with a speed count unit (4) through an I / O bus; the servo module (3) is connected with a control module (7) used for controlling an X, a Z, an XI, a U and a D shafts of a machine tool; the speed count unit (4) is connected respectively with a first sensor (5) and a second sensor (6) through data lines; and the automatic detecting device uses a Siemens 840 D numerical control system and the developed special process control software to complete the grinding process and the control logic of the whole grinder. The automatic detecting device has the advantages of high control accuracy, improves the work efficiency of the machining tool, and reduces the labor intensity of an operator.

Owner:TIANSHUI SPARK MACHINE TOOL

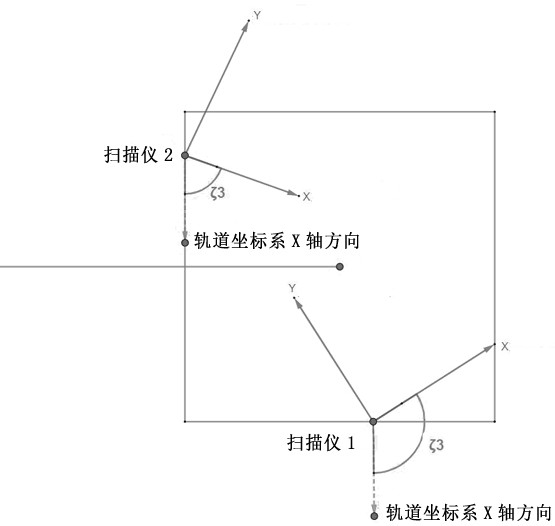

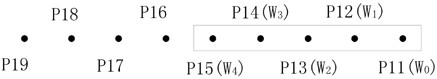

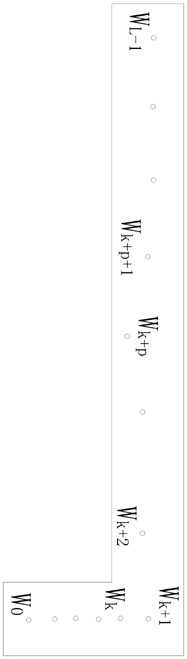

Ship loader cabin hatch identification method

ActiveCN113340287AHigh precisionComputable DepthActive open surveying meansUsing optical meansPoint cloudMarine engineering

The invention discloses a ship loader cabin hatch identification method, and solves the problem that a ship body and coal cannot be correctly identified in the prior art. The method comprises the following steps: acquiring point clouds of two laser scanners, calculating a conversion matrix between coordinate systems, performing sliding window detection by taking each scanning line acquired by the laser scanners as a basic unit to extract boundary points, clustering the boundary points to select a final boundary point cloud set, converting the final boundary point cloud set to a track coordinate, fitting a contour line for the final boundary point cloud set, and calculating the cabin depth and the cabin gradient. According to the method, the coordinate data of the point cloud data is adopted to carry out coordinate conversion, elimination and contour line extraction on the point cloud, and the situation that the ship body and the coal cannot be distinguished due to similar point cloud reflectivity intensity is eliminated. A sliding window detection method is utilized, so that the accuracy of determining the hatch boundary point is improved. The depth and the inclination of the cabin can be calculated by using a hatch identification processing result, and real-time monitoring data can be provided for ship loading process control software.

Owner:HANGZHOU JIYI TECH

Impregnation automatic control system in production of short fiber stock solution viscose

ActiveCN102393692AReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention provides an impregnation automatic control system in production of short fiber stock solution viscose. The conventional automatic control system is improved and optimized, and a redundant process control system is constructed by redundant process control software, so that the impregnation automatic control system in the production of the short fiber stock solution viscose is established. The concentration of pulp is controlled by controlling the feeding speed and addition amount of the pulp and the addition amount of impregnation alkali; a feeding system comprises a pulp feeder and an impregnation alkali feeding pipe which are provided with devices for controlling the feeding amount of the pulp and the impregnation alkali; and the concentration of the pulp has been adjusted during feeding, so that the influence of other interference factors in the subsequent impregnation process is greatly reduced.

Owner:YIBIN HIEST FIBER +1

Continuous-evacuation automatic control system for crude short-fiber viscose production

ActiveCN102505152AReal-time controlEffective controlFilament-forming treatmentTotal factory controlAutomatic controlControl system

The invention provides a continuous-evacuation automatic control system for crude short-fiber viscose production, which is set up by modifying and optimizing an existing automatic control system, and using redundancy process control software to set up a redundancy process control system. By controlling evacuation vacuum degree, viscose supply and viscose discharge and highly integrating a controller and a sensor to equipment through the modified continuous-evacuation automatic control system, occupation of a production site is relieved, continuous evacuation capacity and evacuation quality are improved, and continuous production is realized.

Owner:YIBIN HIEST FIBER +1

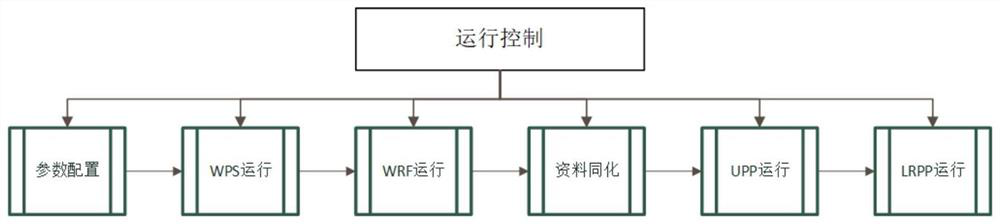

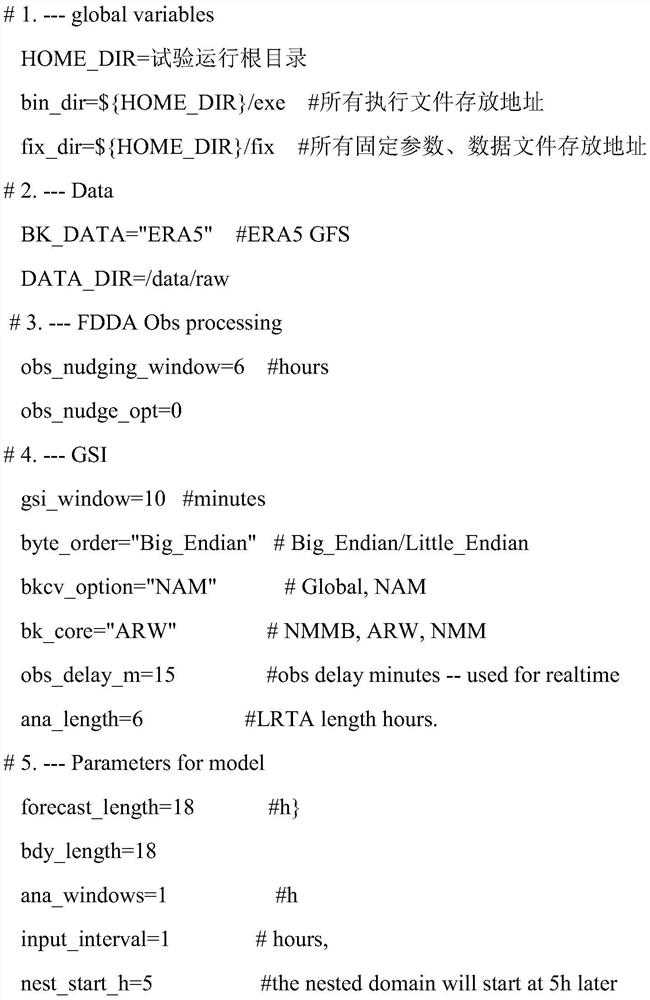

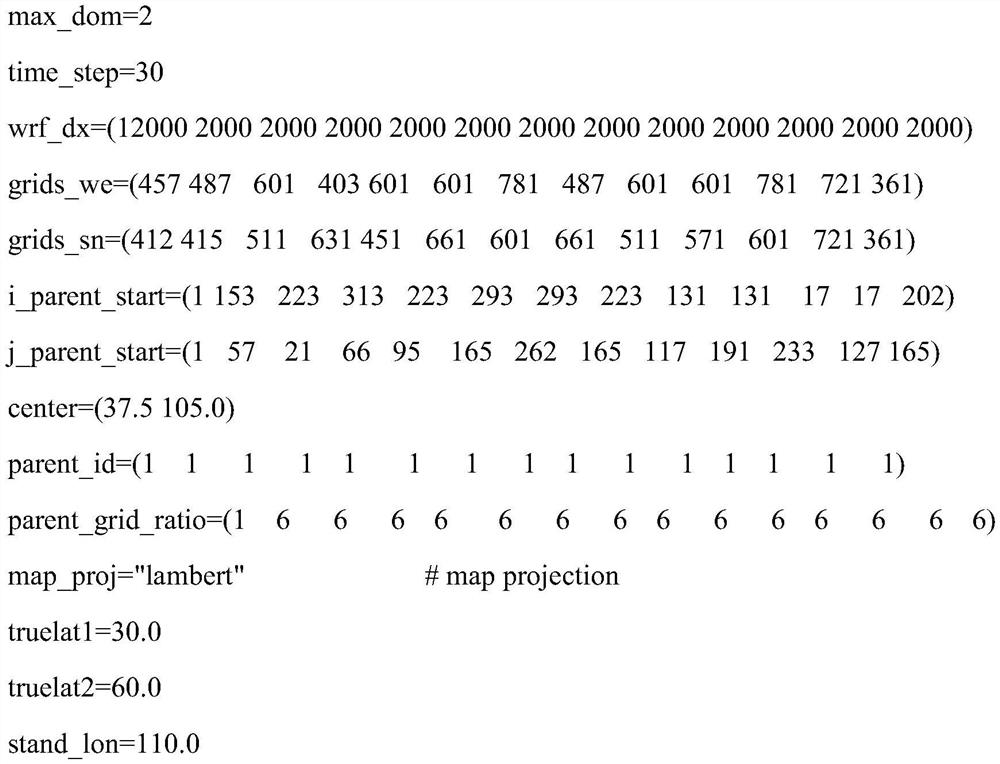

Mesoscale wind energy resource analysis automatic operation system based on Linux system bash script control

The invention discloses a mesoscale wind energy resource analysis automatic operation system based on Linux system bash script control. The system comprises a parameter configuration script file, a mesoscale mode WRF preprocessing WPS running script file, a mesoscale mode WRF running script, a data assimilation script file, a mode post-processing data assimilation script file, a mode product generation LRPP script file and a running control script file. Complex operation process control software such as rocoto, ECflow and Airflow which are commonly used in meteorological services is avoided, and functions of submitting, operating, monitoring, supplementary calculation and the like of the operation are realized by adopting a simple bash script; wherein all parameter configurations are set in a parameter configuration script file, and other scripts adopt a modular method to realize operation in any mode; the regional range of the large lattice point number is divided into a plurality ofrelatively small lattice point regions for mesoscale simulation, and region splicing is carried out in the product stage.

Owner:HUANENG NEW ENERGY CO LTD +2

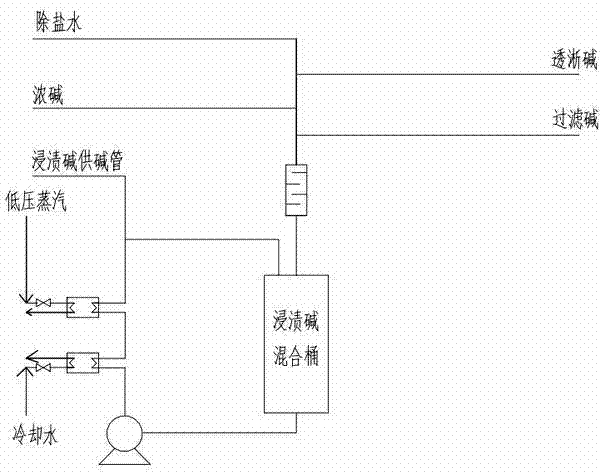

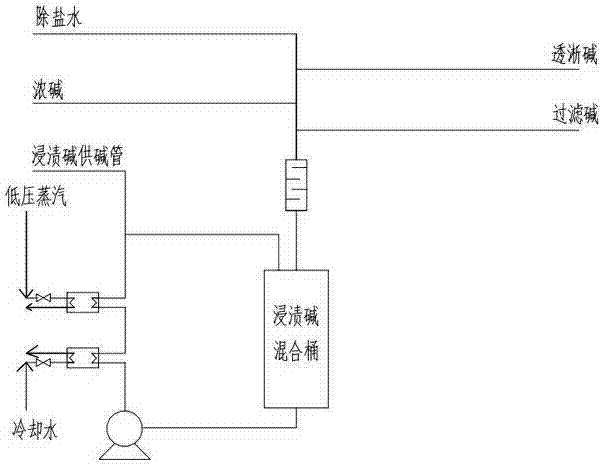

Impregnation alkali blending automatic control system in production of short fiber stock solution viscose

InactiveCN102393695AReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention provides an impregnation alkali blending automatic control system in production of short fiber stock solution viscose. The conventional automatic control system is improved and optimized, and a redundant process control system is constructed by redundant process control software, so that the impregnation alkali blending automatic control system in the production of the short fiber stock solution viscose is established. The control system controls the addition amount of an impregnation alkali raw material, performs comparative analysis on set values of the control system to control the flow rate of each medium, and accurately blends impregnation alkali at required concentration, so that the quality of the subsequent impregnation process and the quality of alkaline fibers obtained by the impregnation process are ensured.

Owner:YIBIN HIEST FIBER +1

Yellowing automatic control system in production of short fiber stock solution viscose

ActiveCN102393694BReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention provides a yellow automation control system in the production of short -fiber jelly glue. By improving and optimizing the existing automatic control system, the redundant process control software is used to build a redundant process control system.The automatic control system in production, including the control unit in order: alkaline fiber feed control unit, real vacuum control unit, CS2 feed control unitMaterial control unit and yellow chemical machine flushing control unit; this control system can accurately control the amount of materials added to each material, ensure the quality of sticky glue after the last yellowing, reduce artificial labor, save costs, and improve production efficiency.

Owner:YIBIN HIEST FIBER +1

Automatic control system in production of short fiber stock solution viscose

ActiveCN102393691BReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system design

The invention provides an automatic control system in production of short fiber stock solution viscose, belongs to the field of artificial fibers, and aims to solve the problems that a distributed control system (DCS) cannot comprehensively control the production of the short fiber stock solution viscose as a whole and control operation is complicated in the prior art. A redundant process control system is constructed by redundant process control software, so that an impregnation alkali blending automatic control system, a pulp impregnation automatic control system, an alkaline fiber pressing automatic control system, an alkaline fiber automatic ageing control system, an alkaline fiber yellowing automatic control system and a viscose ripening automatic control system are established to automatically control each link in the production, the long-period continuous operation of the whole production process is ensured, and the process cannot be influenced due to the failure of the automatic control system; and the control system is reasonable in design and simple in control steps, and manual labor is greatly reduced.

Owner:YIBIN HIEST FIBER +1

Continuous-evacuation automatic control system for crude short-fiber viscose production

ActiveCN102505152BReal-time controlEffective controlFilament-forming treatmentTotal factory controlAutomatic controlControl system

The invention provides a continuous-evacuation automatic control system for crude short-fiber viscose production, which is set up by modifying and optimizing an existing automatic control system, and using redundancy process control software to set up a redundancy process control system. By controlling evacuation vacuum degree, viscose supply and viscose discharge and highly integrating a controller and a sensor to equipment through the modified continuous-evacuation automatic control system, occupation of a production site is relieved, continuous evacuation capacity and evacuation quality are improved, and continuous production is realized.

Owner:YIBIN HIEST FIBER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com