Strain strengthening pressure device and pressure method for austenitic stainless steel low-temperature vessel

A technology of austenitic stainless steel and pressurization device, which is applied in the processing of austenitic stainless steel low-temperature containers and in the field of industrial automatic control. It can solve problems such as difficult control of product quality, rising production costs, and declining production efficiency, so as to achieve energy-saving operation, Effects of improving control accuracy and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

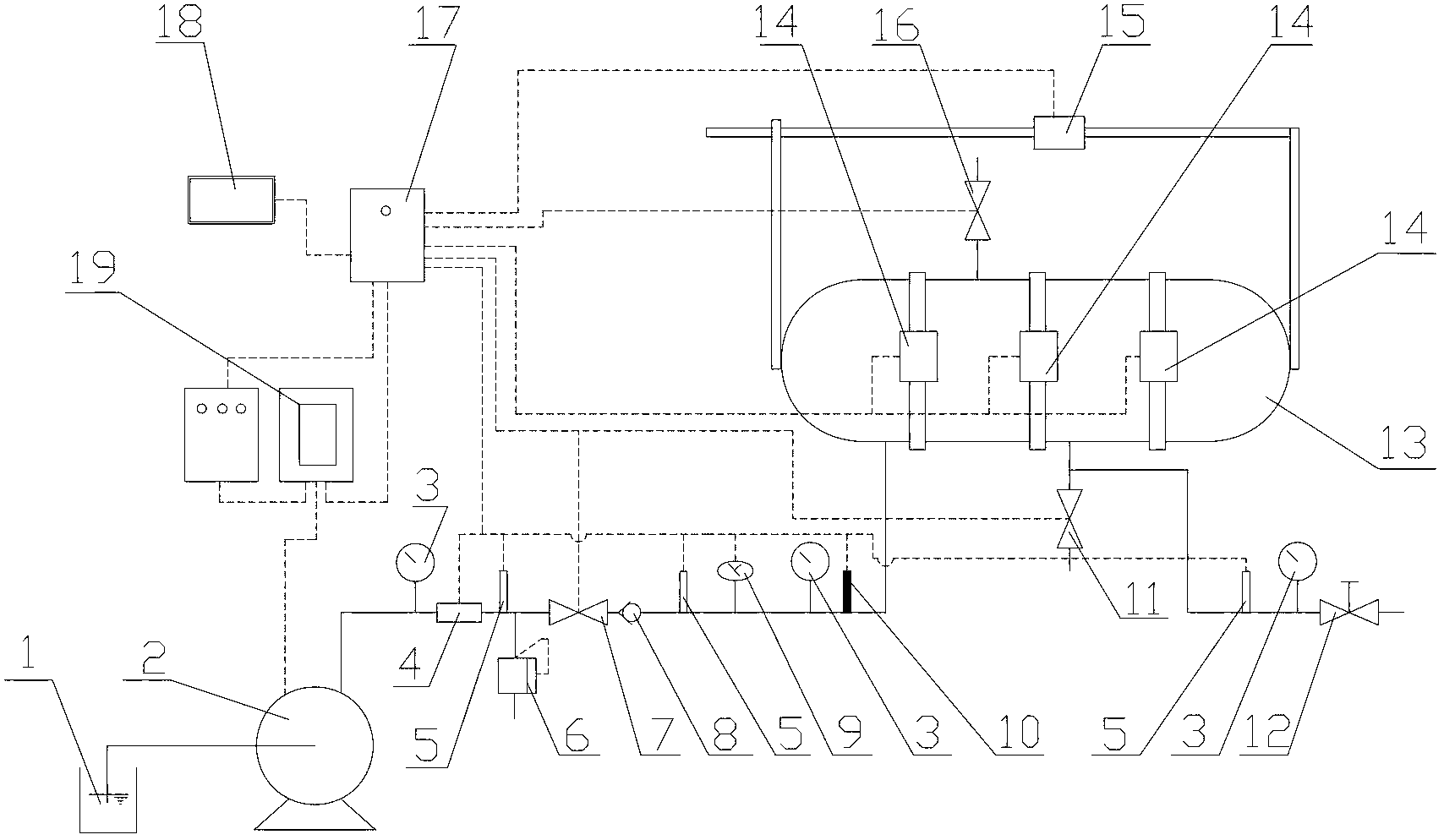

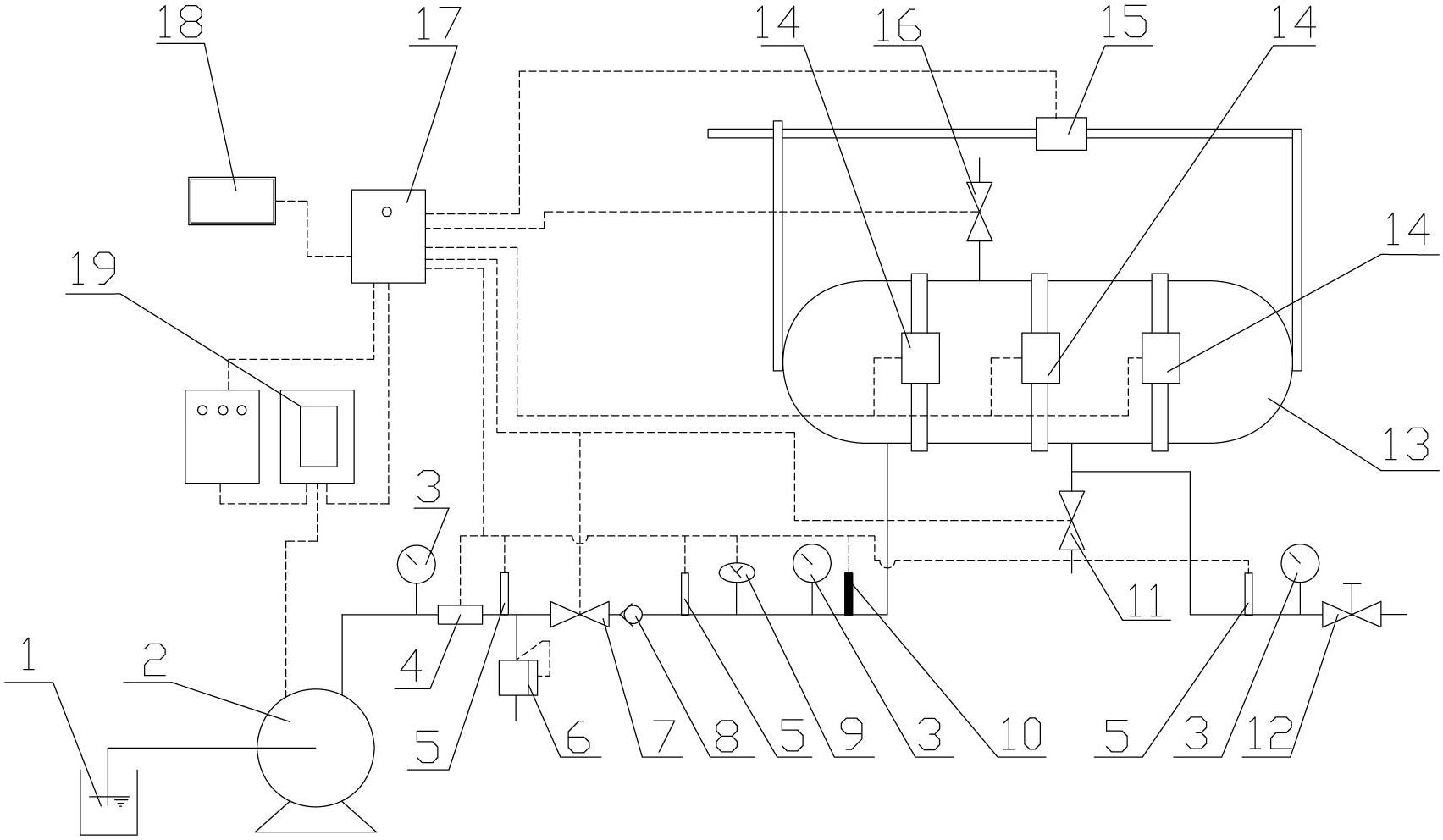

[0028] The present invention is an austenitic stainless steel cryogenic container strain strengthening pressurization device, such as figure 1 As shown, it includes an electric high-pressure water pump 2, a shaft length change sensor 15, three circumference change sensors 14, a frequency converter 19, a measurement and control signal processor 17 and a computer 18, and the circumference change sensor 14 is loaded on the On the circumference of the container 13 (austenitic stainless steel container), axial length change sensors 15 are loaded on the two axial ends of the container 13 to be processed.

[0029] The pipeline between the electric high-pressure water pump 2 and the container 13 to be processed is provided with a pressure sensor transmitter 5, a first electric stop valve 7, a check valve 8, an electric contact pressure gauge 9, a pointer pressure gauge 3, Temperature transmitter 10, flowmeter 4 and overflow valve 6; The signals detected by the flowmeter 4, temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com