Automatic detection apparatus and control method for roll grinder

An automatic detection device, roll grinder technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as difficult to meet the requirements, achieve the effect of reducing labor intensity, high control precision, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

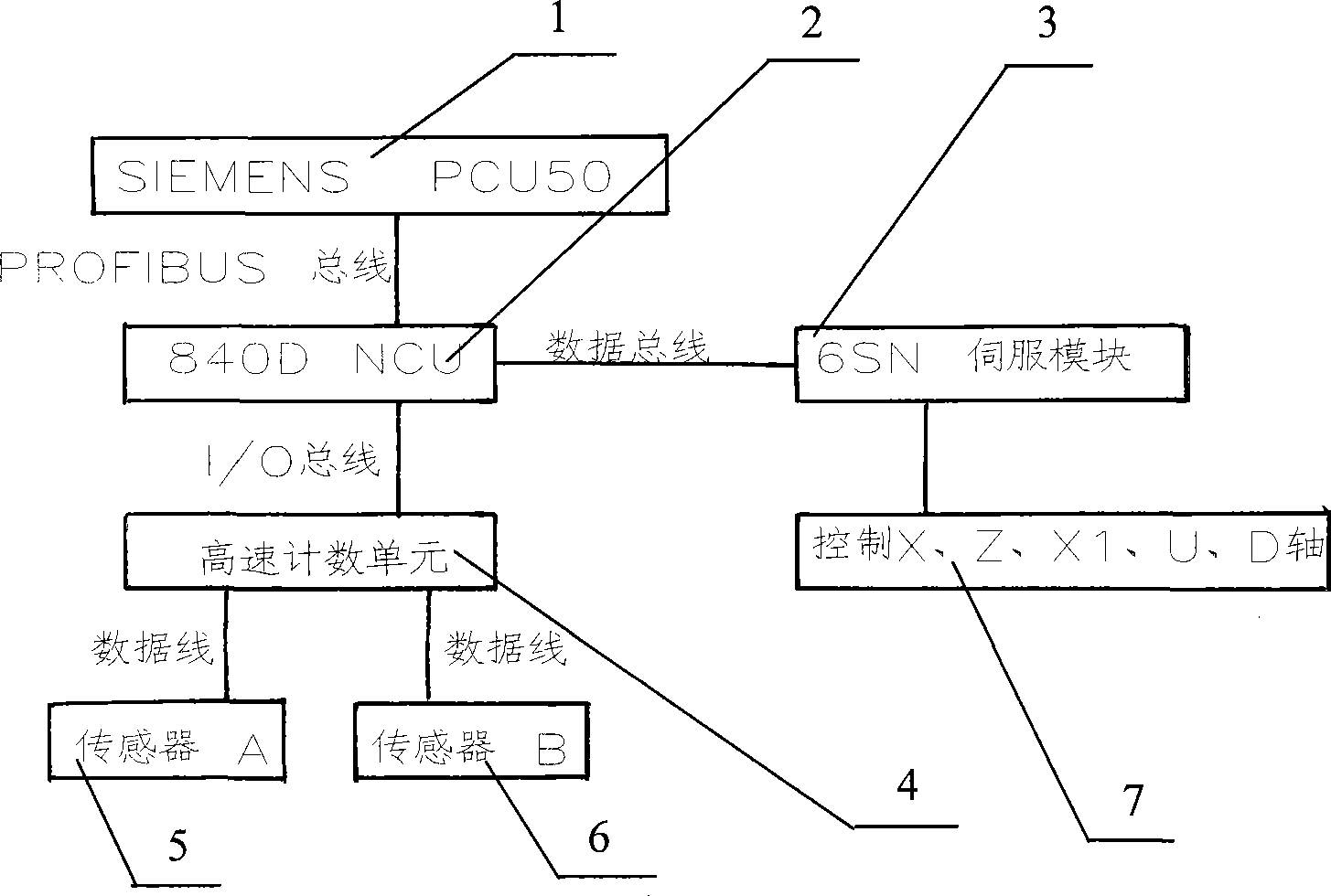

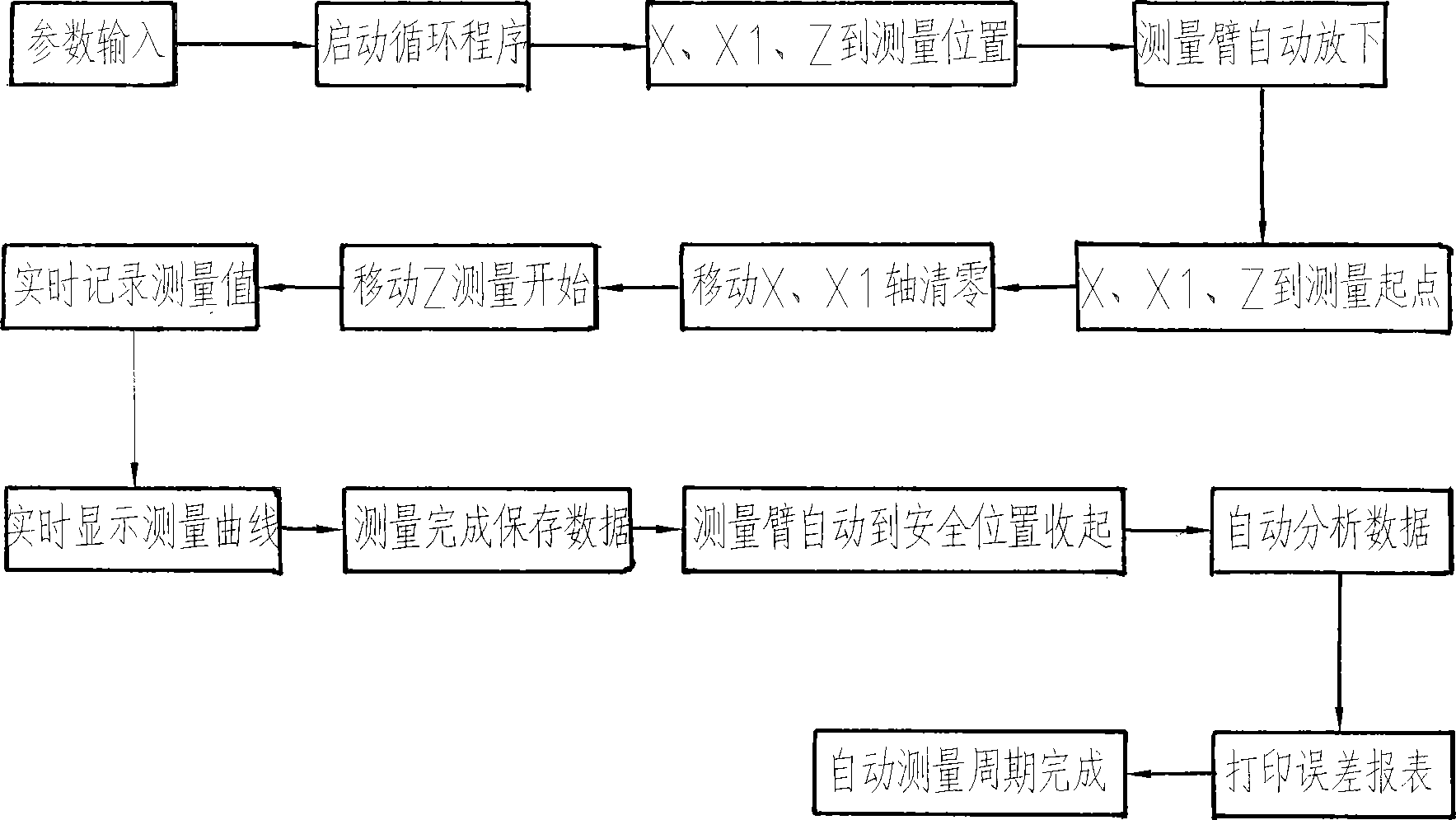

[0024] Example 1, see figure 1 , 2 , the described roll grinding machine automatic detection device and control method include a SIEMEN man-machine interface 1, the man-machine interface 1 is connected with the control system 2 through the PROFBUS data bus, and its feature also includes the control system 2 through the data bus and The servo module 3 is connected, the control system 2 is connected with the high-speed counting unit 4 through the I / O bus, the servo module 3 is connected with the control module 7 for controlling the X, Z, X1, U, D axes of the machine tool, and the high-speed counting unit 4 passes The lines are respectively connected with the first sensor 5 and the second sensor 6; the steps of the automatic detection and control of the roll grinder include:

[0025] (1) Parameter input, including diameter and measurement cycle parameters;

[0026] (2) Start the cycle program, according to the selected measurement process (including diameter, standard ring, rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com