Impregnation alkali blending automatic control system in production of short fiber stock solution viscose

An automatic control system, the technology of impregnating alkali, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of affecting the concentration of impregnating alkali, unable to accurately control the amount of various raw materials added, and achieve real-time control of the process. , the effect of saving communication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

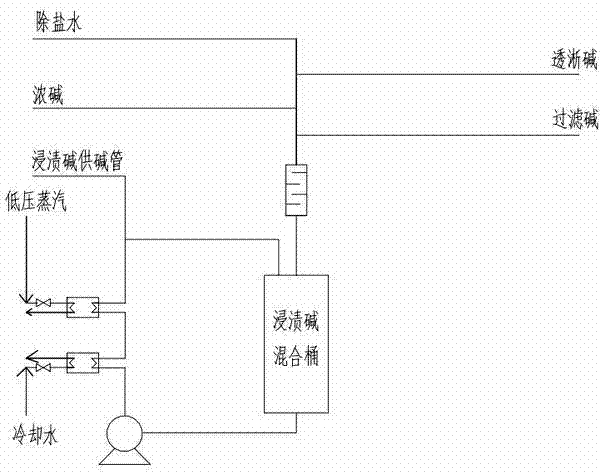

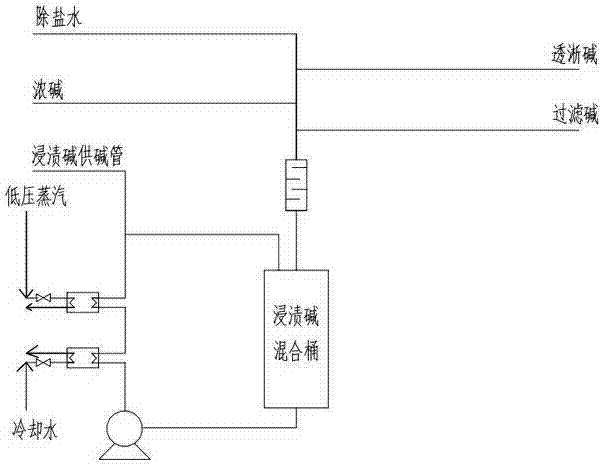

[0028] The impregnation alkali blending automatic control system in the production of short fiber stock solution viscose, including impregnation alkali raw material delivery pipe, impregnation alkali supply pipe and impregnation alkali mixing tank, is characterized in that it also includes an upper computer operation station for receiving and analyzing signals , the upper computer operation station uses redundant process control software to build a redundant process control system to establish an automatic control system for impregnating alkali deployment in the production of short fiber stock solution viscose; the impregnating alkali raw material delivery pipe described in the present invention is provided with A flow PID controller and a flow control valve connected thereto are used to control the concentration of impregnation alkali; the flow PID controller is connected to the upper computer operation station; the impregnation alkali supply pipe is also provided with an impre...

Embodiment 2

[0039] The impregnation alkali blending automatic control system in the production of short fiber stock solution viscose, including the impregnation alkali raw material delivery pipe, the impregnation alkali supply pipe and the impregnation alkali mixing tank, is characterized in that it also includes an upper computer operation station for receiving and analyzing signals , the upper computer operation station uses redundant process control software to build a redundant process control system to establish an automatic control system for impregnating alkali deployment in the production of short fiber stock solution viscose; the impregnating alkali raw material delivery pipe of the present invention is provided with A flow PID controller and a flow control valve connected thereto are used to control the concentration of impregnation alkali; the flow PID controller is connected to the upper computer operation station; the impregnation alkali supply pipe is also provided with an imp...

Embodiment 3

[0050] The impregnation alkali blending automatic control system in the production of short fiber stock solution viscose, including impregnation alkali raw material delivery pipe, impregnation alkali supply pipe and impregnation alkali mixing tank, is characterized in that it also includes an upper computer operation station for receiving and analyzing signals , the upper computer operation station uses redundant process control software to build a redundant process control system to establish an automatic control system for impregnating alkali deployment in the production of short fiber stock solution viscose; the impregnating alkali raw material delivery pipe described in the present invention is provided with A flow PID controller and a flow control valve connected thereto are used to control the concentration of impregnation alkali; the flow PID controller is connected to the upper computer operation station; the impregnation alkali supply pipe is also provided with an impre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com