Method of realizing automatic block clearing and continuous operation of up flow type ash cabin pump

An ash bin, automatic technology, applied in the direction of combustion method, removal of solid residue, treatment of combustion products, etc., can solve problems such as blockage, achieve the effect of overcoming defects, avoiding blockage, and increasing the gas phase concentration steadily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

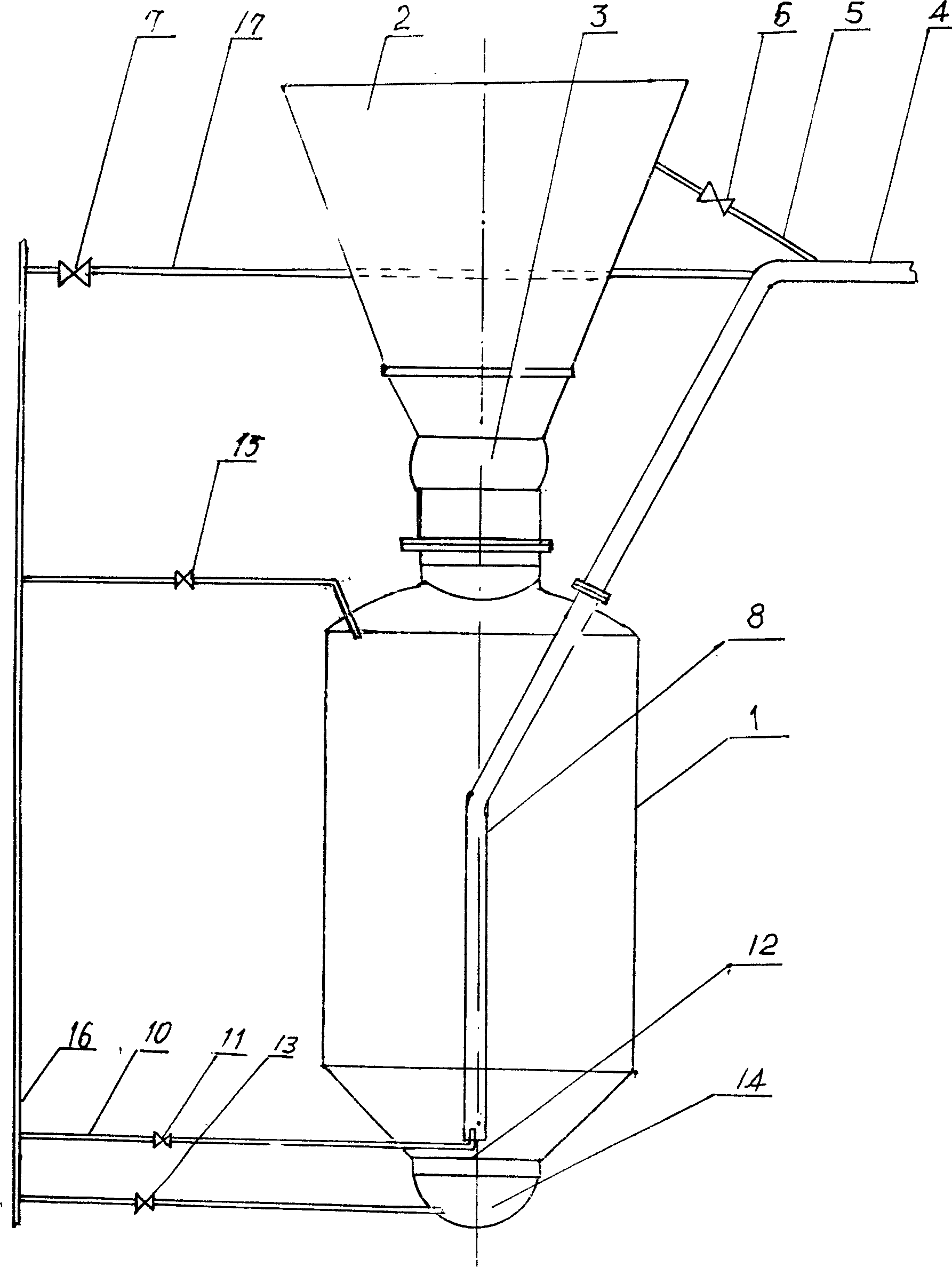

[0033] With reference to the accompanying drawings, it can be clearly understood that the content of the present invention is to make a key improvement to the original upward ash bin pump structure, and on the basis of the improvement, an automatic blockage removal method in the online state is designed. On the basis of this, the automatic and continuous operation of the ascending ash bin pump has been redesigned.

[0034] The method of automatic blockage removal is realized by means of the complete set of configuration in the existing ash bin pump system, the central processor in the control circuit and the process control software stored in EEPROM. The key is:

[0035] ① An ash discharge pipe 5 is set between the main ash conveying pipe 4 and the ash storage hopper 2, and a controlled ash discharge valve 6 is set in the pipeline. ②Pressure sensors are respectively installed in the upper space of the main ash conveying pipe 4 and the chamber pump body 1. ③Standard pressure da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com