Automatic control system in production of short fiber stock solution viscose

An automatic control system, short fiber technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of cumbersome control operations, inability to control short fiber raw liquid viscose, etc., to save communication time, improve productivity. The effect of spinning and reducing the probability of incorrect operation of hair production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

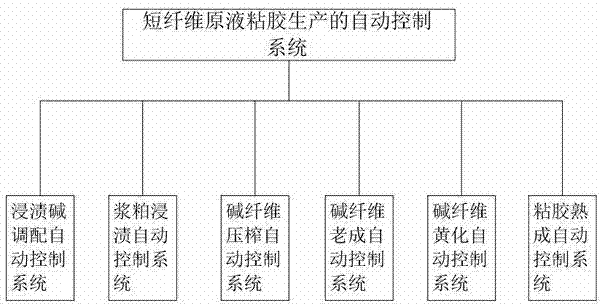

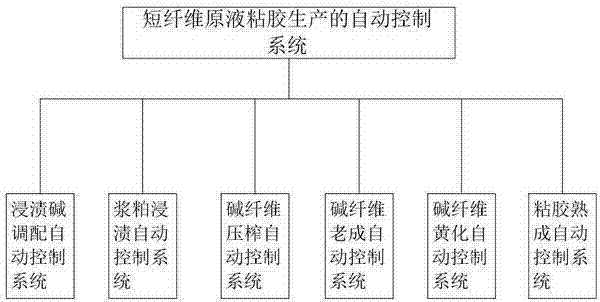

[0053] The automatic control system for the production of short fiber raw liquid viscose is characterized in that it includes an upper computer operation station for receiving and analyzing signals, and the upper computer operation station adopts redundant process control software to build a redundant process control system to establish a dipping process. Alkali blending automatic control system, pulp impregnation automatic control system, alkali fiber pressing automatic control system, alkali fiber aging automatic control system, alkali fiber yellowing automatic control system and viscose ripening automatic control system.

[0054] The system of the invention is supplemented by a multi-operating station network structure, message alarm records and process history curves to ensure that the entire control process is real-time, effective and traceable.

[0055] The upper computer operating station of the present invention adopts Siemens S7-400H CPU as the control core.

[0056] ...

Embodiment 2

[0078] The impregnation alkali deployment automatic control system in the present invention mainly controls the concentration and temperature of the impregnation alkali:

[0079] It includes impregnation alkali raw material delivery pipe, impregnation alkali supply pipe and impregnation alkali mixing tank. The impregnation alkali raw material delivery pipes with different concentrations are equipped with flow PID controllers and flow control valves connected thereto to collect the impregnation alkali raw materials with different concentrations. Flow information, calculate the demand for different concentrations of lye through the set concentration and density parameters of the impregnated alkali, control the flow of different concentrations of impregnated alkali raw materials by controlling the flow control valve, and prepare the concentration in the impregnated alkali mixing tank. The impregnation alkali with an alkali content of 160g / l, the prepared impregnation alkali enters...

Embodiment 3

[0084] The impregnation alkali deployment automatic control system in the present invention mainly controls the concentration and temperature of the impregnation alkali:

[0085] It includes impregnation alkali raw material delivery pipe, impregnation alkali supply pipe and impregnation alkali mixing tank. The impregnation alkali raw material delivery pipes with different concentrations are equipped with flow PID controllers and flow control valves connected thereto to collect the impregnation alkali raw materials with different concentrations. Flow information, calculate the demand for different concentrations of lye through the set concentration and density parameters of the impregnated alkali, control the flow of different concentrations of impregnated alkali raw materials by controlling the flow control valve, and prepare the concentration in the impregnated alkali mixing tank. The impregnation alkali with an alkali content of 170g / l, the prepared impregnation alkali enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com