A Distortion Correction Algorithm for the Optical System of a Full View 3D Measuring Instrument

A technology of distortion correction and three-dimensional measurement, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of reducing geometric position accuracy and measurement error, and achieve the effect of reducing optical system distortion and improving angle measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

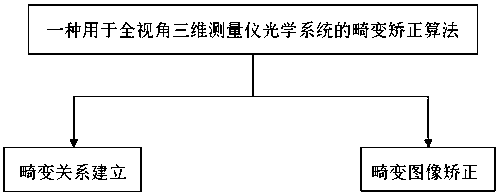

[0020] Specific implementation mode one: as figure 1 As shown, the distortion correction algorithm for the optical system of a full-view 3D measuring instrument provided by this embodiment is composed of two parts: the establishment of the distortion relationship and the correction of the distorted image, wherein:

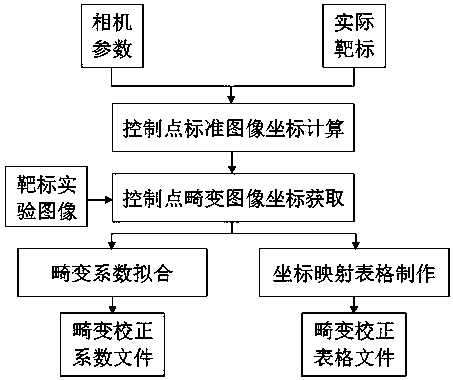

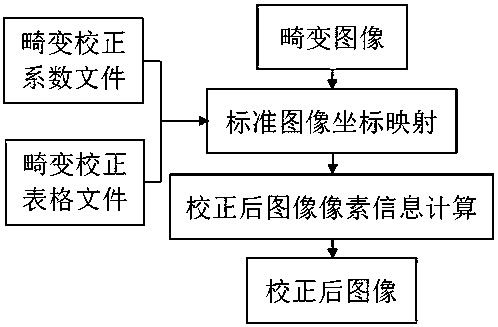

[0021] The establishment of the distortion relationship is to construct the mapping relationship between the standard image and the coordinates of the distorted image. Such as figure 2 As shown, the specific steps are as follows:

[0022] 1) According to the camera parameters provided by the user and the actual target, the standard image coordinates of the control points are calculated using the ideal imaging projection relationship;

[0023] 2) Obtain the coordinates of the control points in the distorted image coordinate system according to the actual distorted target image;

[0024] 3) If the distortion relationship is described using the function expression...

specific Embodiment approach 2

[0031] Specific implementation mode two: as Figure 4 As shown, this embodiment provides a visible light optical system for a full-view three-dimensional measuring instrument. The visible light optical system is composed of a low-distortion wide-angle imaging optical lens 1 and a linear array CMOS camera 2. The linear array CMOS camera 2 and the low-distortion wide-angle The imaging optical lens 1 is fixed together, and the low-distortion wide-angle imaging optical lens 1 clearly images the collected visible light image on the focal plane of the line array CMOS camera 2 .

[0032] Such as Figure 5 As shown, the low-distortion wide-angle imaging optical lens 1 adopts the F-Theta lens structure, so that the spatial angular resolution is directly proportional to the number and size of the camera. Low-distortion wide-angle imaging optical lens 1 has a focal length of 26.07, which is more than three times the focal length of ordinary wide-angle imaging objective lenses. The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com