Short-shaft keyboard switch

A keyboard switch and casing technology, which is applied in the direction of electric switches, tactile feedback, electrical components, etc., can solve the problems of unsightly appearance of the keyboard switch, the sound of impact is not crisp, and the volume of the keyboard switch is large, so as to improve the dustproof effect, Effect with crisp sound and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

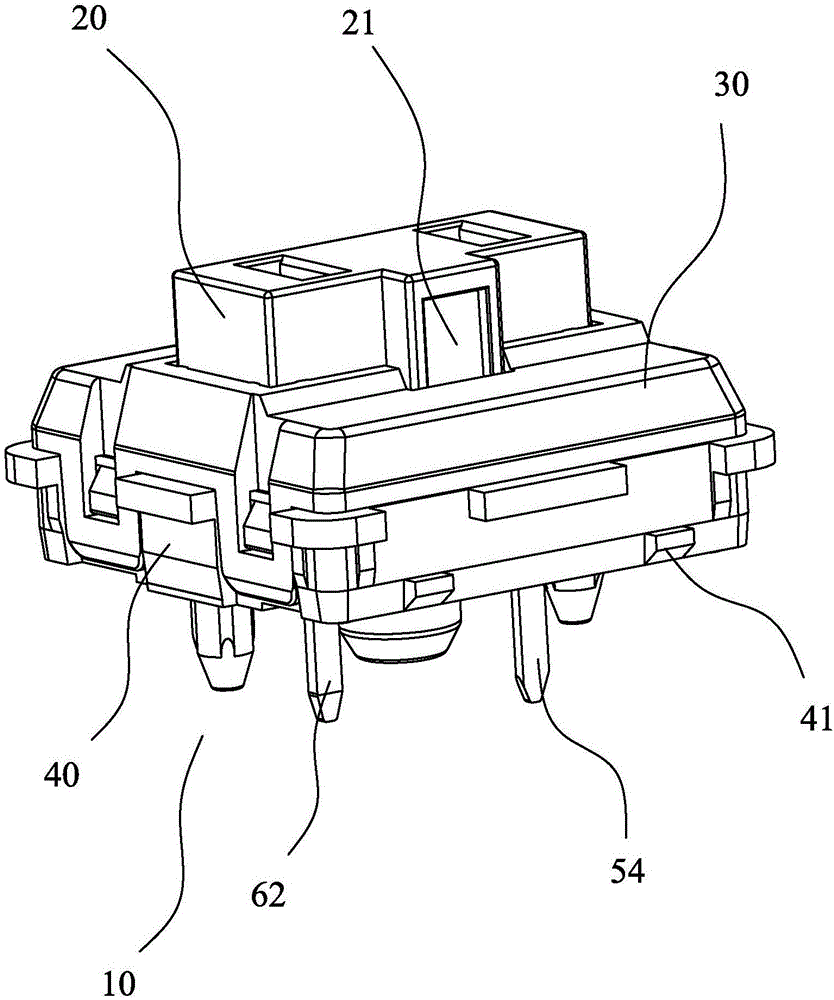

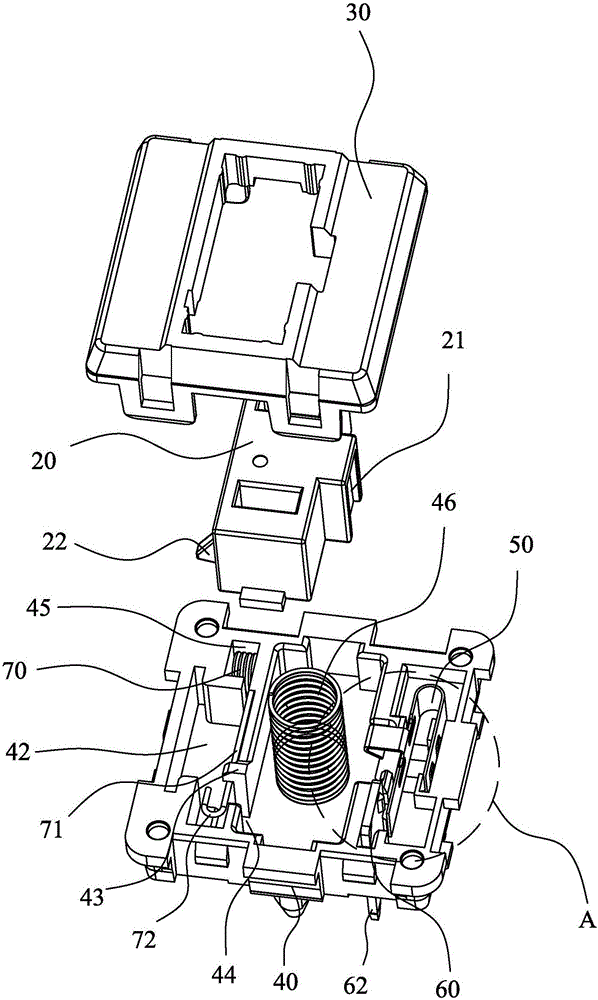

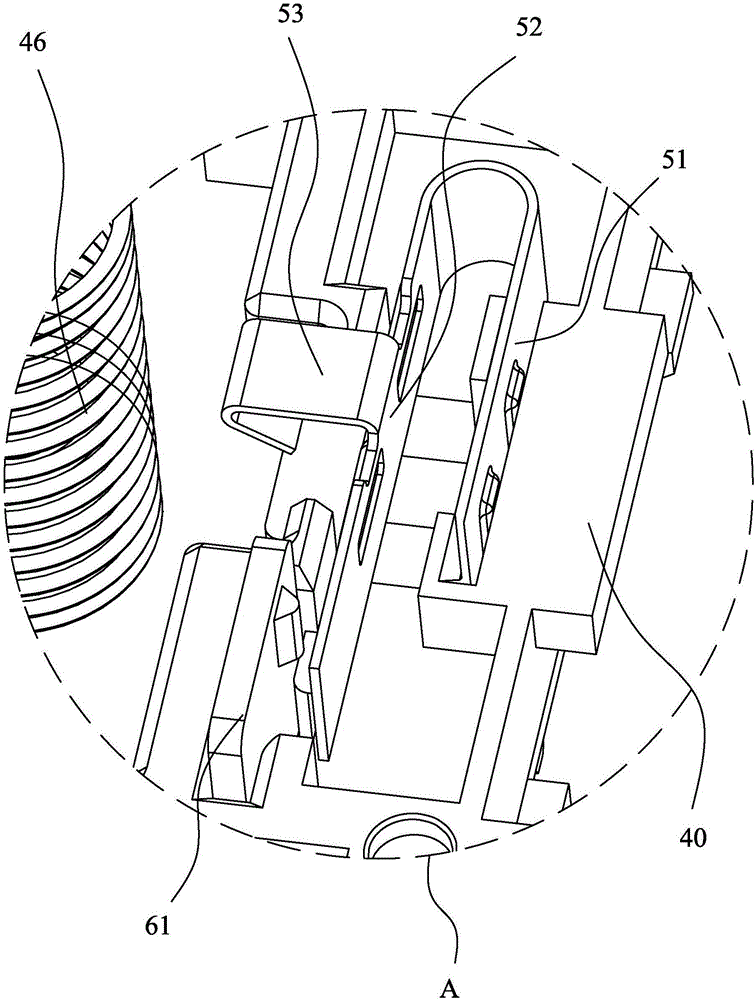

[0032] Such as Figure 1-4 As shown, a low-axis keyboard switch includes a pressing member 20, an upper housing 30 and a lower housing 40 snap-connected with the upper housing 30; the lower housing 40 is provided with a movable contact piece 50, a static contact Plate 60, torsion spring 70 and accommodating groove 45 for installing torsion spring 70, the movable contact piece 50 includes a first fixed plate 51 arranged transversely and a movable plate 52 formed by bending laterally from one end of the first fixed plate 51 The upper end of the middle part of the movable plate 52 is provided with an extruding plate 53 formed by bending outwards, and the pressing member 20 is provided with an extruding portion 21 for extruding the extruding plate 53, and the extruding portion 21 is Extrusion groove adapted to the extrusion plate 53; the lower housing 40 is provided with a first limit groove adapted to the first fixed plate 51 of the movable contact piece 50, and the first fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com