A kind of fuel cell and its preparation method and fuel cell anode material

A technology for fuel cells and anode materials, which is applied in fuel cells, battery electrodes, solid electrolyte fuel cells, etc., can solve the problems of complex preparation process of SOFC electrodes, limited metal material addition, and high production costs, and achieves good regulation and service life. long, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a fuel cell, comprising: coating the anode material of the fuel cell on one side of the electrolyte support, and at the same time coating the cathode material on the other side of the electrolyte support, and sintering at a temperature of 800-900°C 1~5h.

[0029] The electrolyte support is made of Zr 2 O-based electrolyte or CeO 2 Based on electrolyte. Both types of electrolytes are commonly used in fuel cells and have a wide range of applications. Preferably, the electrolyte support is made of Y 2 O 3 Stable ZrO 2 (YSZ) made. YSZ has good oxygen ion conductivity at high temperature and high stability in oxidizing and reducing atmospheres, and is considered to be the material of choice for high-temperature electrolytes. Further, the surface of YSZ is also coated with Sm 2 O 3 Doped CeO 2 (SDC) functional layer. YSZ has low ion conductivity at medium temperature (500-800℃), which leads to poor battery performance. Add CeO 2 The basic functional lay...

Embodiment 1

[0035] This embodiment provides a fuel cell, which is manufactured by the following steps:

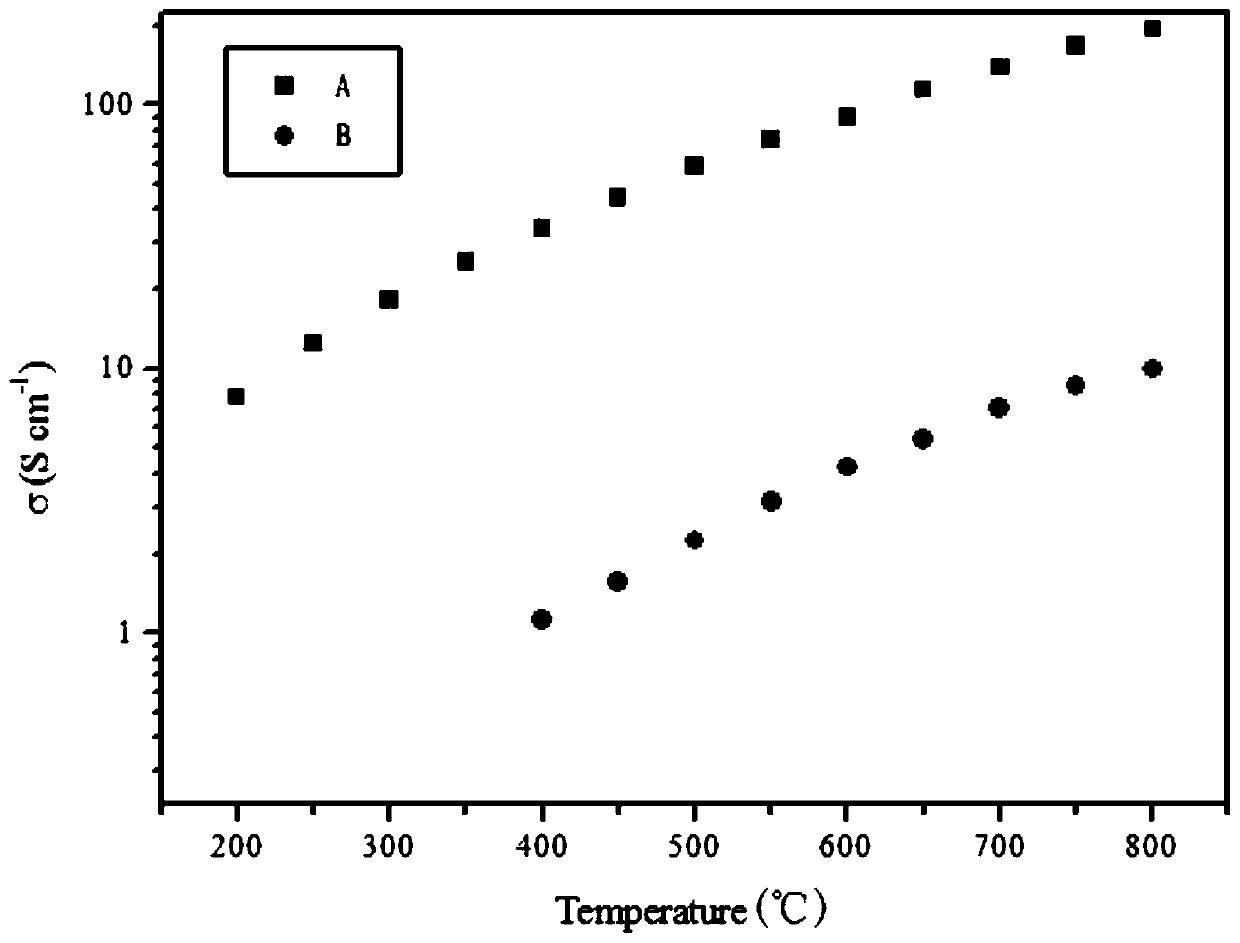

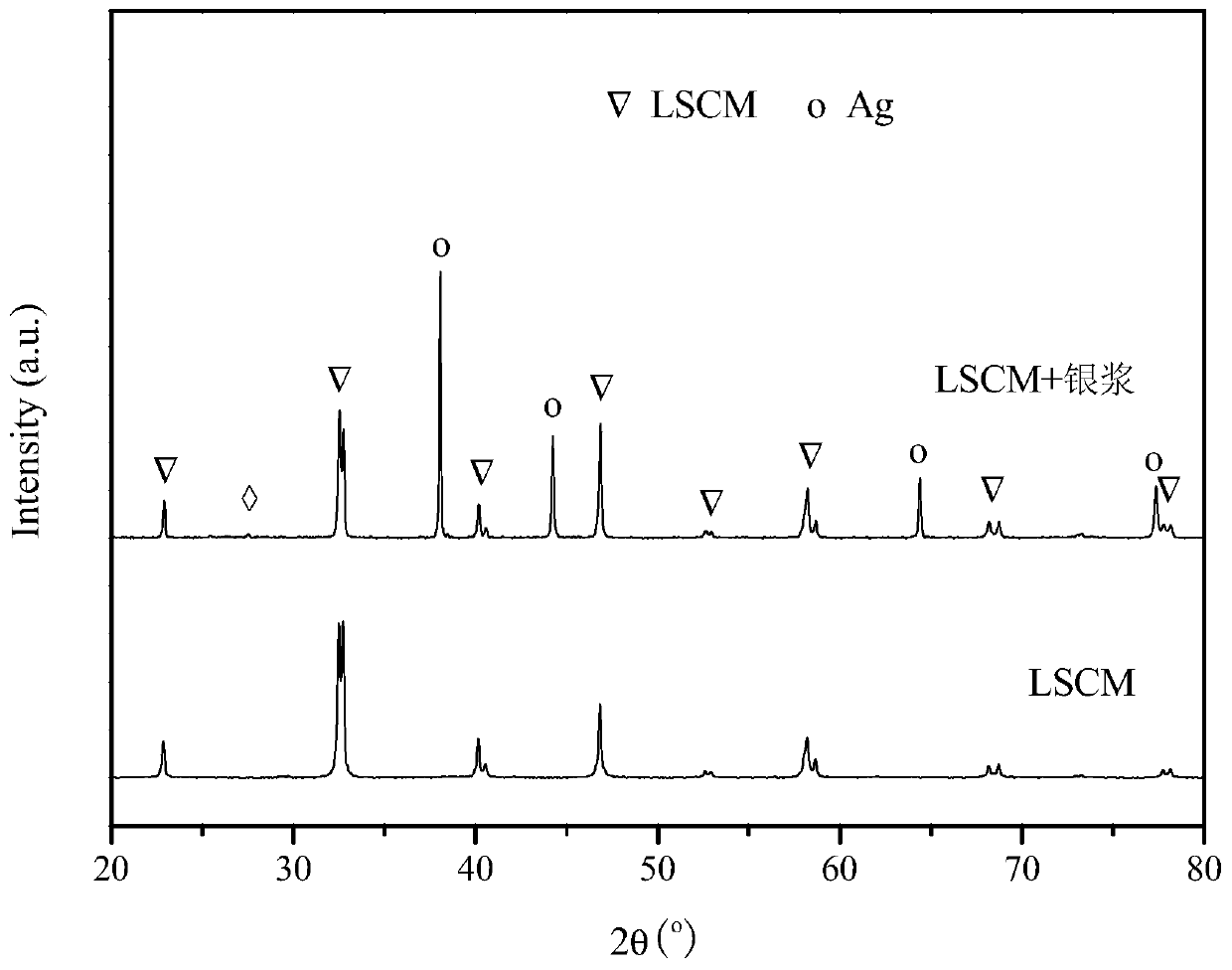

[0036] S1. Preparation of La by solid-phase reaction method 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ Anode precursor powder.

[0037] S2, the synthesized La 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ Silver paste and binder are added to the anode precursor powder, where La 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ The mass ratio of anode precursor powder to silver paste is 1:0.25, the mass ratio of ethyl cellulose to terpineol in the binder is 1:20, and the binder content is La 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ 1.5 times the total mass of anode precursor powder and silver paste. After being fully stirred and evenly mixed, a fuel cell anode material is obtained.

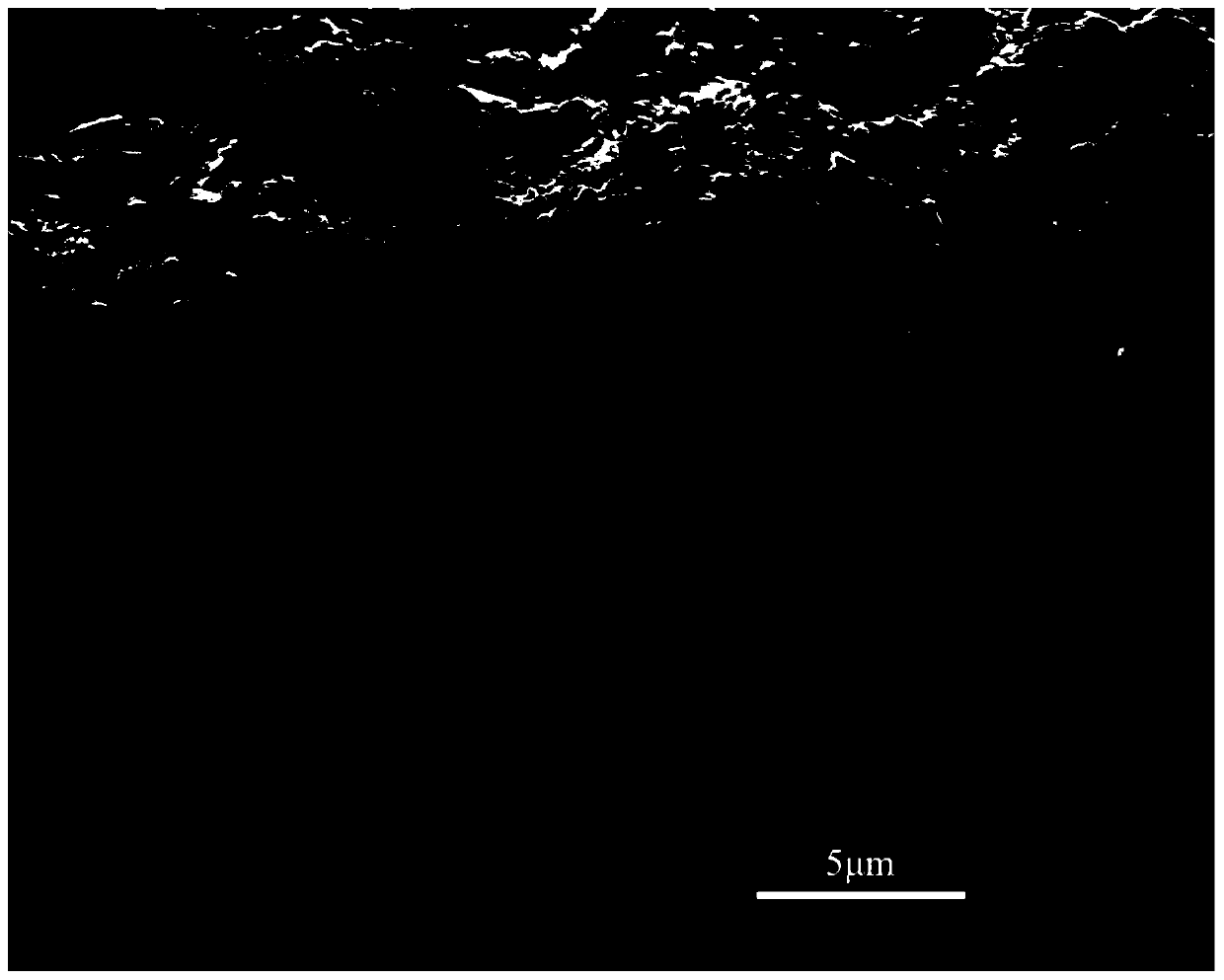

[0038] S3. Use YSZ electrolyte coated with SDC functional layer to make an electrolyte support, and use screen printing to coat the fuel cell anode material on one side of the electrolyte support. At the same time, prepare the LSM cathode on the other side of t...

Embodiment 2

[0040] This embodiment provides a fuel cell, which is manufactured by the following steps:

[0041] S1. Preparation of La by solid-phase reaction method 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ Anode precursor powder.

[0042] S2, the synthesized La 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ Silver paste and binder are added to the anode precursor powder, where La 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ The mass ratio of anode precursor powder to silver paste is 1:0.43, the mass ratio of ethyl cellulose to terpineol in the binder is 1:20, and the binder content is La 0.75 Sr 0.25 Cr 0.5 Mn 0.5 O 3-δ 1.5 times the total mass of anode precursor powder and silver paste. After being fully stirred and evenly mixed, a fuel cell anode material is obtained.

[0043] S3. Use YSZ electrolyte coated with SDC functional layer to make an electrolyte support, and use screen printing to coat the fuel cell anode material on one side of the electrolyte support. At the same time, prepare the LSM cathode on the other side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com