Power battery thermal management method and system

A thermal management system, power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of lack of battery temperature rising trend, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

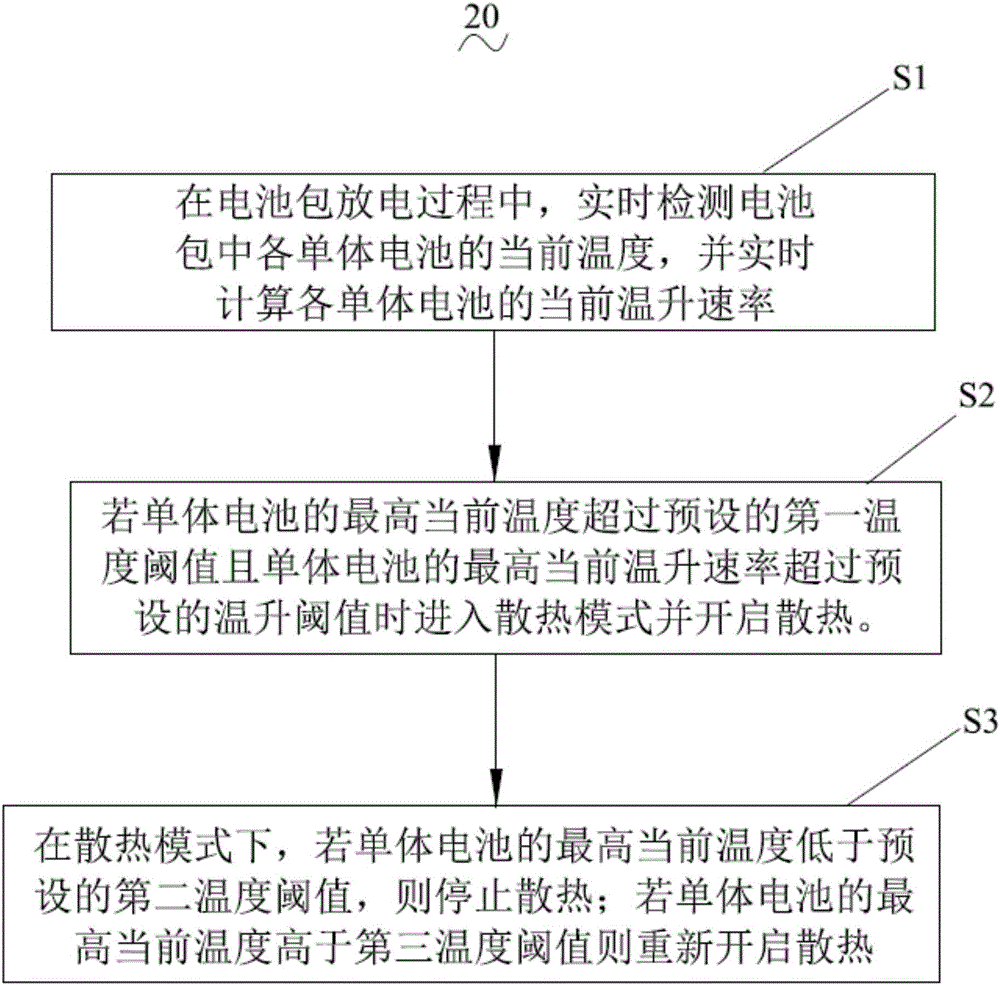

[0054] see figure 1 , a power battery thermal management method 20, applied to a charging process or a discharging process of a battery pack, comprising the following steps:

[0055] Step S1, during the discharge process of the battery pack, detect the current temperature of each single battery in the battery pack in real time, and calculate the current temperature rise rate of each single battery in real time.

[0056] Step S2, if the highest current temperature of the single battery exceeds the preset first temperature threshold and the highest current temperature rise rate of the single battery exceeds the preset temperature rise threshold, enter the heat dissipation mode and turn on heat dissipation. Specifically, the first temperature threshold is preferably 28°C to 32°C. In this embodiment, 30° C. is used as an example; the temperature rise threshold is preferably 1° C. / min˜3° C. / min. In this embodiment, 2°C / min is selected as an example.

[0057] Step S3, in the heat...

Embodiment 2

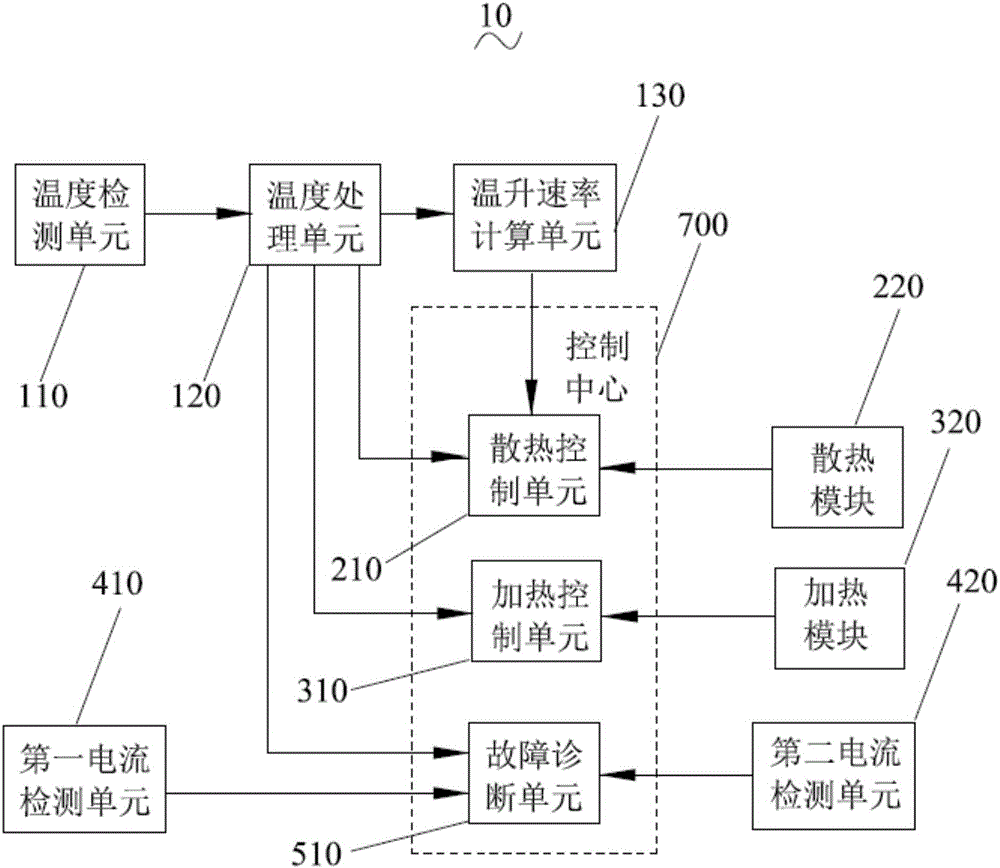

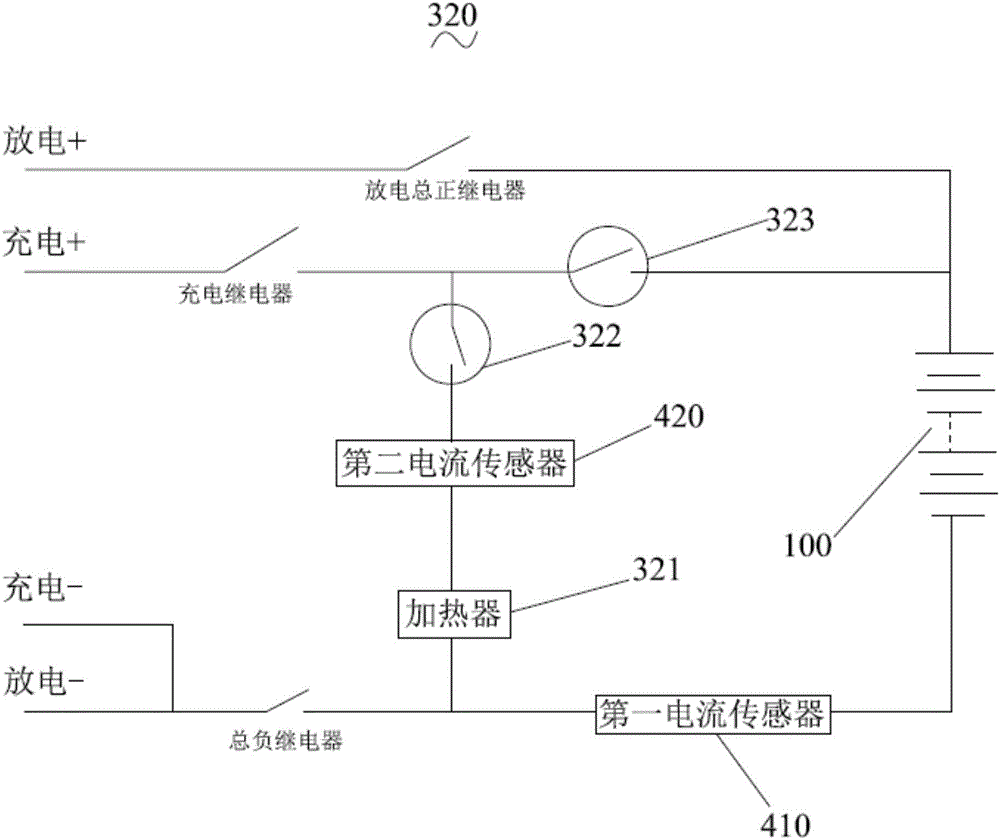

[0073] see figure 2 , the present invention also provides a power battery thermal management system 10, which includes: a temperature detection unit 110, which detects the current temperature of each single battery in the battery pack in real time. The temperature processing unit 120 judges the validity of the current temperature of each single battery, and eliminates invalid temperature values. The temperature rise rate calculation unit 130 calculates the current temperature rise rate of each single battery according to the current temperature of each single battery after removing invalid temperature values. The heat dissipation control unit 210 controls the working state of the heat dissipation module according to the current temperature of each single battery and the current temperature rise rate of each single battery after removing invalid temperature values. The heat dissipation module 220 performs corresponding operations according to the control instructions of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com