Engine and motor insulation end cover insulation structure

A technology of insulating structure and insulating end, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of decreased insulation performance, easy inhalation of water, and high water absorption, so as to reduce the impact and prevent the occurrence of electrical corrosion and creepage of the rotating shaft. The effect of increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The purpose of the present invention is to provide an insulation structure for generator and motor insulation end cover, which has simple structure, safe and reliable insulation performance, and can effectively increase the creepage distance.

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

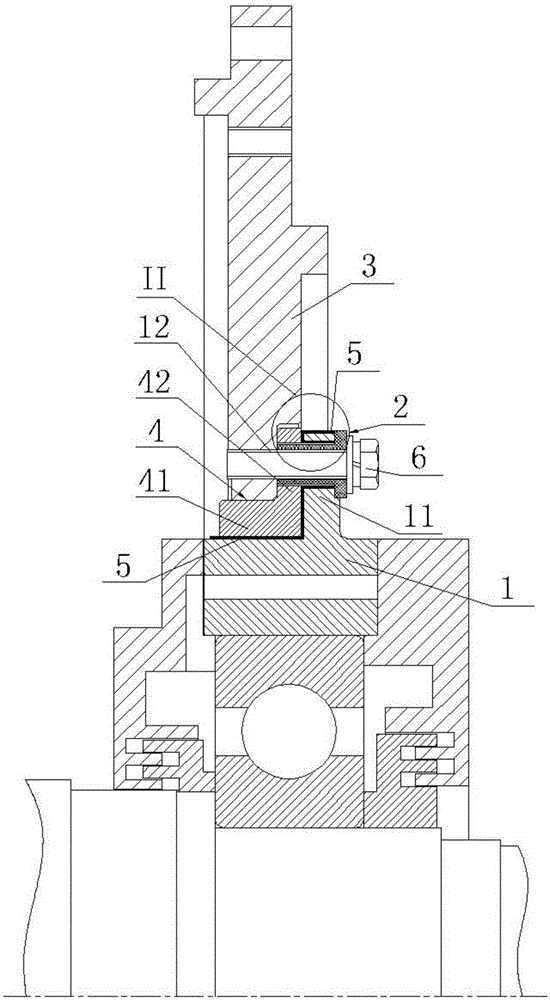

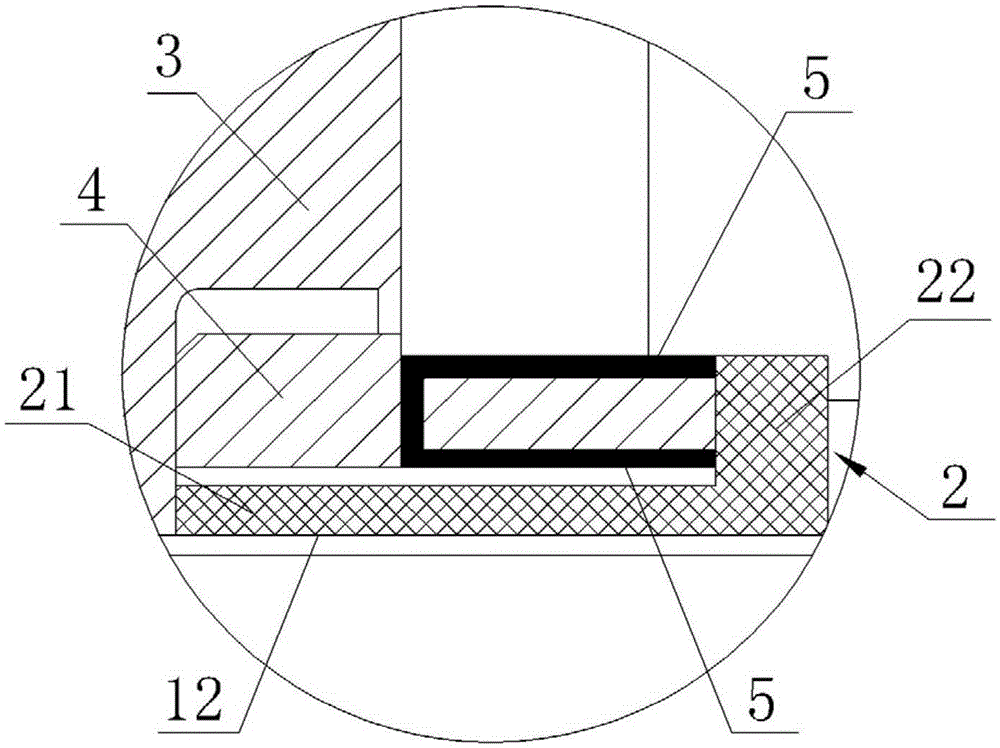

[0025] Such as figure 1 shown and figure 2 as shown, figure 1 It is a schematic diagram of the insulation structure of the generator and motor insulation end cover provided by a specific embodiment of the present invention, figure 2 for figure 1 The enlarged schematic diagram at II in the middle shows the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com