Production scheduling command system

A production scheduling and command system technology, applied in transmission systems, closed-circuit television systems, instruments, etc., can solve the problems of high supervision and management costs, and achieve the effects of strengthening effective control, facilitating viewing, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

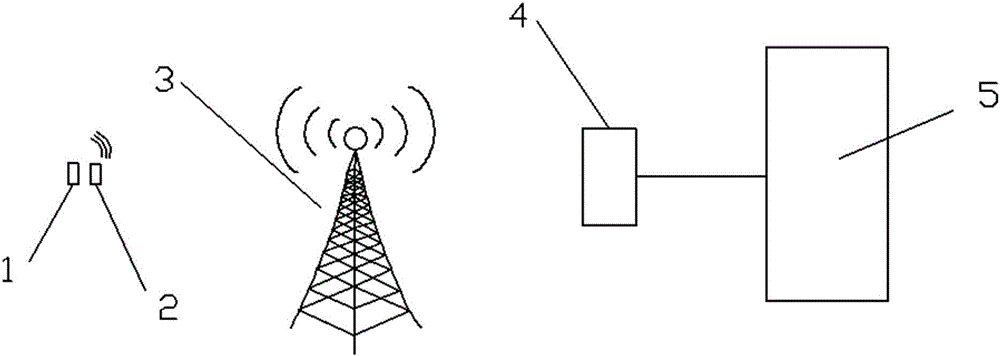

[0035] The technical solution adopted by the present invention to achieve its technical purpose is shown in the figure: it includes a production dispatching command system, including a handheld device, the handheld device has a camera, GPS positioning, alarm button, information transmission, data storage, and is used for instant intercom , real-time positioning, photo upload, video surveillance, danger rescue;

[0036] A communication base station 3, the communication base station 3 is a telecommunications Tianyi communication base station, which is used to connect the video equipment 2 and the individual equipment 3 to the server respectively;

[0037] Server 4, server 4 is used for receiving and storing data;

[0038] Production scheduling monitoring command platform 5, the production scheduling monitoring command platform is used to process the data received by the server, including the intelligent intercom scheduling platform and the comprehensive monitoring platform;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com