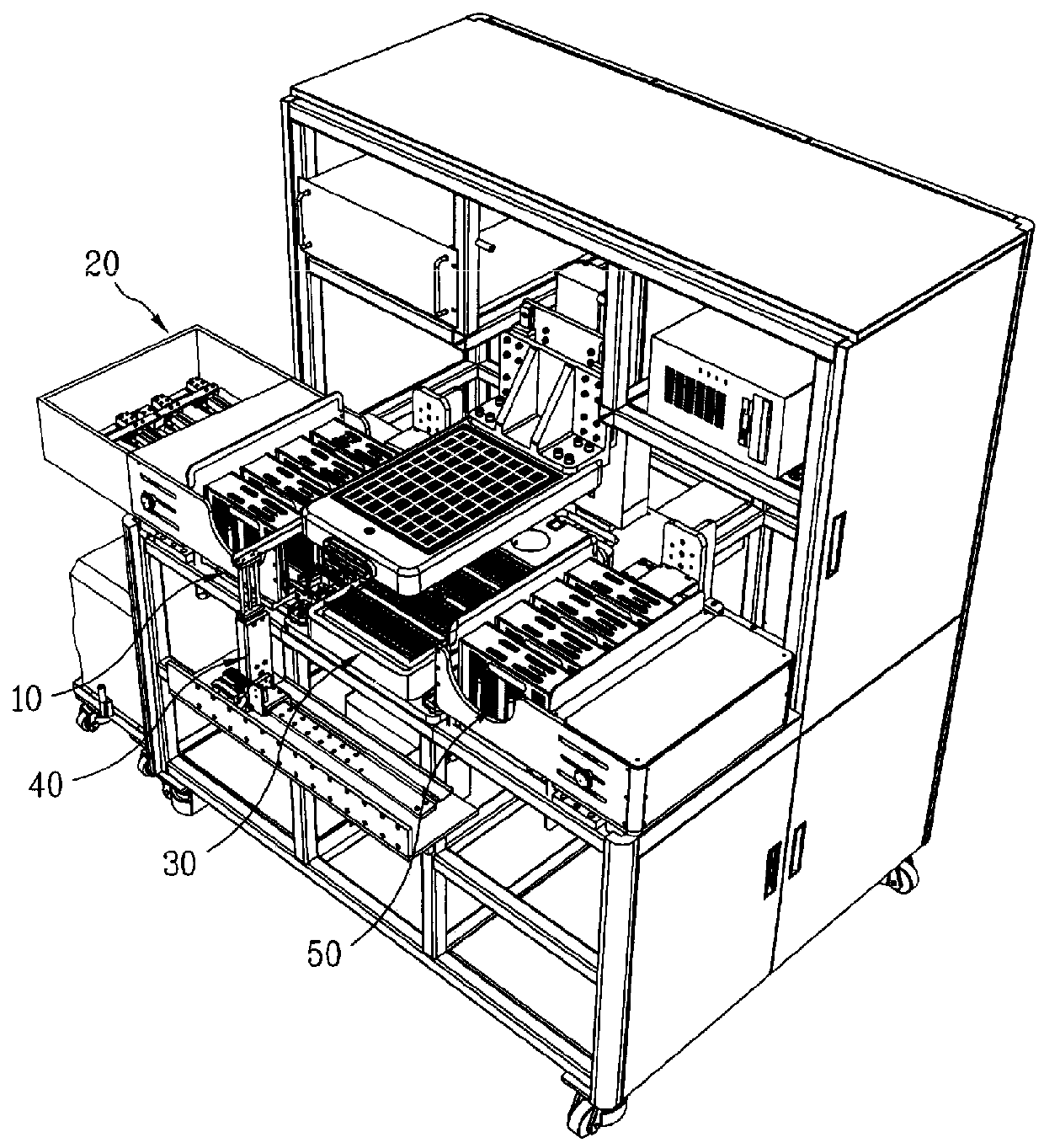

Plasma cleaning equipment for semiconductors

A plasma cleaning and semiconductor technology, which is applied in plasma, semiconductor/solid-state device manufacturing, transportation and packaging, etc., can solve the problems of large size, complex structure, difficult production and operation, etc., and achieve reduced size, simple device structure and logistics management easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The terms or words used in the specification and claims are, in principle, properly defined by the inventors in order to describe their own invention in the best way, and therefore should be interpreted with meanings and concepts consistent with the technical solution of the present invention.

[0023] The following is a detailed description in conjunction with an embodiment of the present invention. The same symbol is used for the same structure, and the description mainly revolves around different parts, so as to avoid repetition and ensure clarity in description.

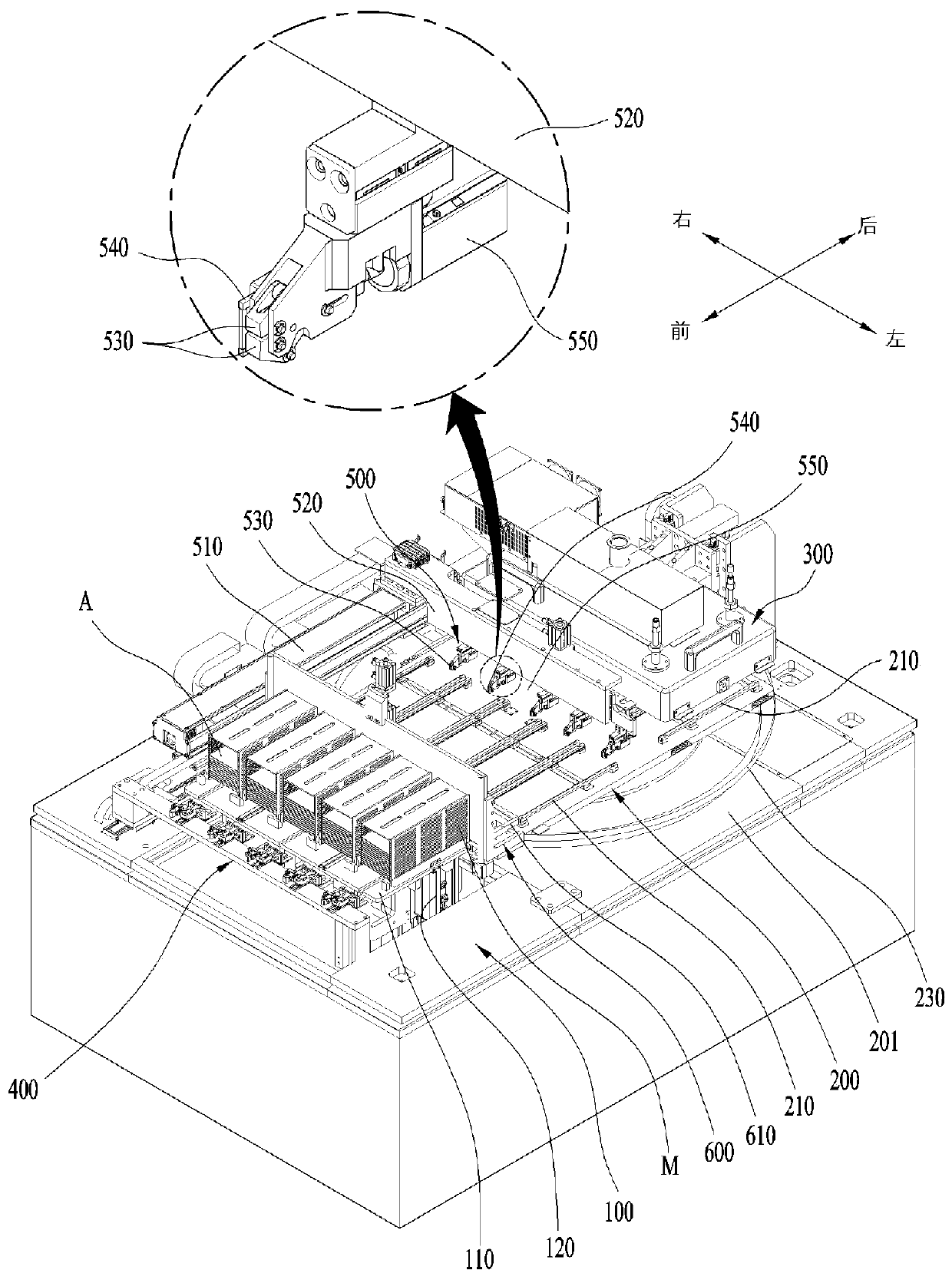

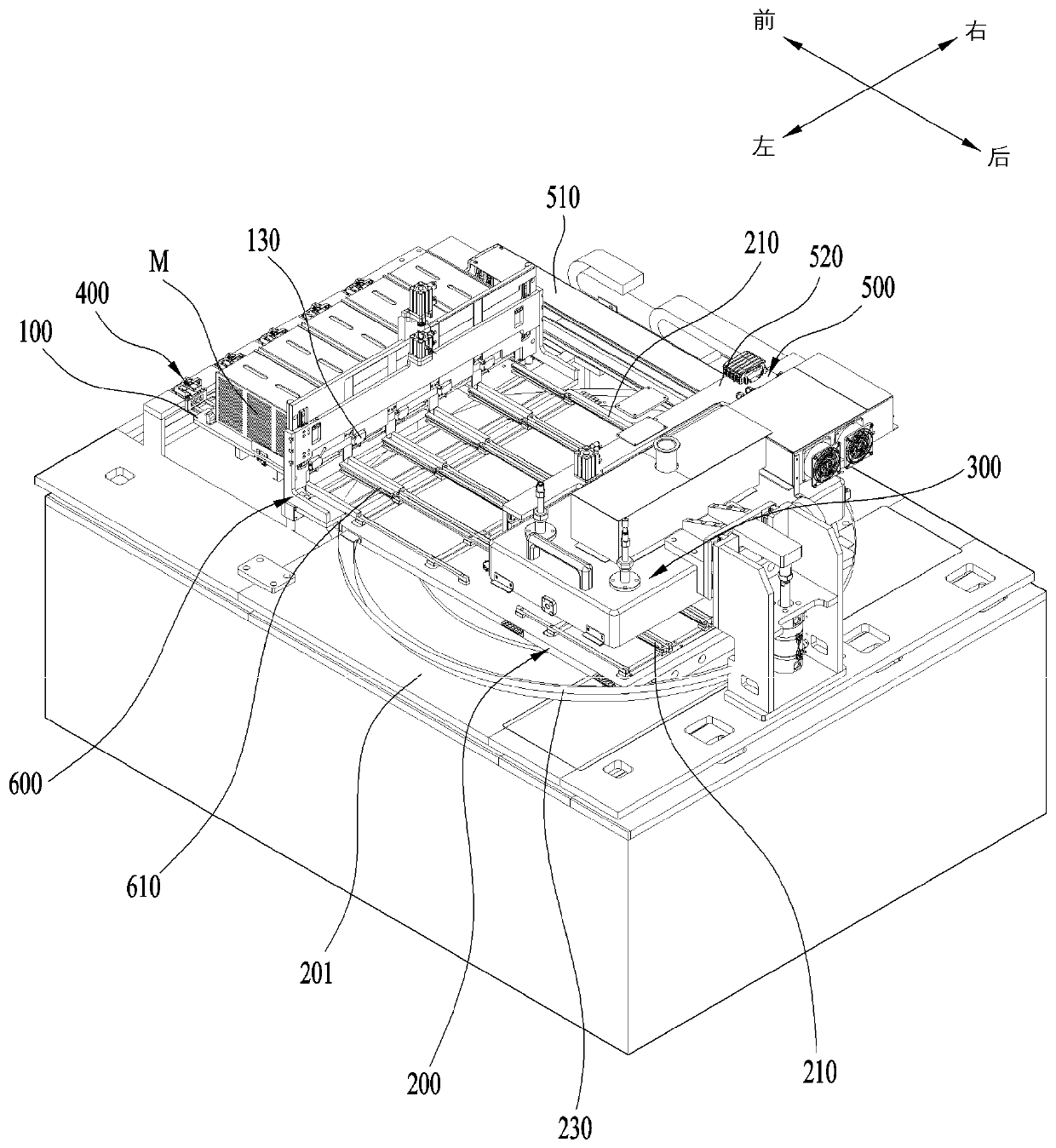

[0024] Such as Figure 2 to Figure 5 As shown, the composition of the semiconductor plasma clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com