Continuous mixing equipment for poultry feed

A technology for mixing equipment and feed, which is applied to feed, mixers, mixers with rotating agitating devices, etc. It can solve the problems of low mixing precision and slow mixing speed, and achieve high mixing precision, fast mixing speed and high product quality. high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

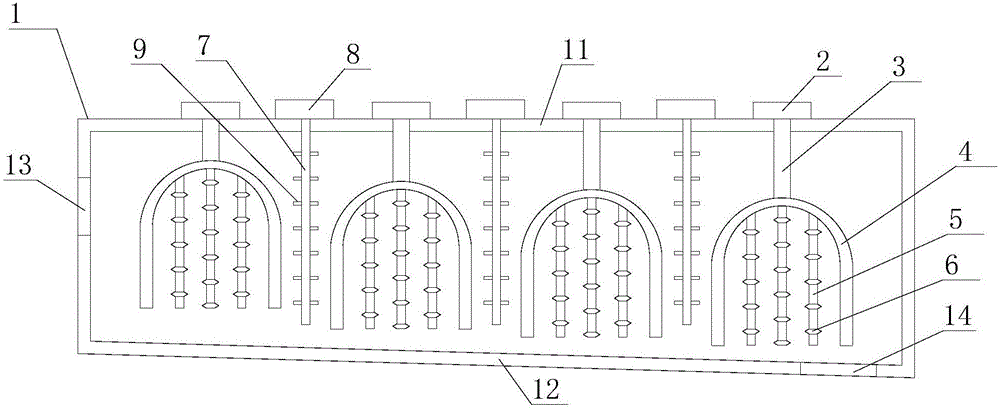

[0016] Such as figure 1 as shown, figure 1 The invention provides a continuous mixing equipment for poultry feed.

[0017] refer to figure 1 , the present invention proposes a continuous mixing equipment for poultry feed, comprising a stirring box 1, a plurality of stirring devices, a first controller, and a second controller, wherein:

[0018] The mixing box 1 is provided with a feed inlet and a discharge opening, the bottom plate 12 of the mixing box 1 is inclined, and the height of the bottom plate 12 of the mixing box 1 near the feeding port 13 is higher than that of the bottom plate 12 of the mixing box 1 near the discharge port 14 the height of one end. The feed to be stirred is continuously added into the mixing box 1 from the feeding port 13, and the mixed feed is discharged from the feeding port 14, and the bottom plate 12 is arranged at an inclination, which is conducive to speeding up the discharging speed and avoiding the accumulation of feed in the mixing box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com