Oil bottle mouth capable of preventing oil leakage during pouring

A bottle nozzle and oil bottle technology, applied in the field of oil bottle nozzles, can solve the problems of grease waste, pouring out of oil, oil leakage, etc., and achieve the effects of convenient use, avoiding pollution of grease, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

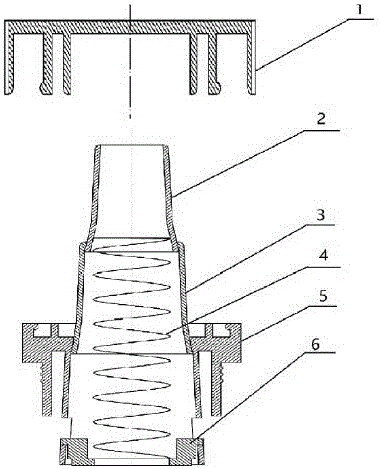

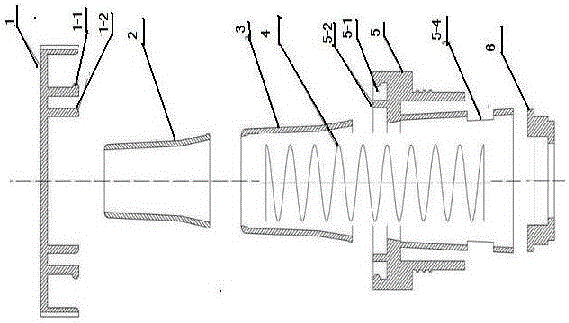

[0019] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, and features of the oil bottle nozzle for preventing oil leakage from pouring according to the present invention are described in detail as follows.

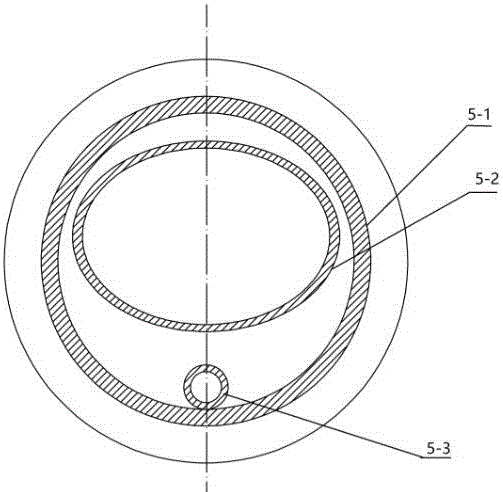

[0020] Referring to the accompanying drawings, an oil bottle mouth for preventing oil leakage from dumping includes a bottle mouth top cover 1, a front telescopic connecting pipe 2, a rear telescopic connecting pipe 3, a tension spring 4, a bottle mouth base 5 and a spring Buckle 6; wherein the bottle mouth top cover 1 and the bottle mouth base 5 are embedded and connected with the concave groove 5-1 on the bottle mouth base 5 through the outer convex rib 1-1 on the bottle mouth top cover 1, and the bottle mouth top cover 1 The sealing groove 1-2 on the top is embedded with the sealing protrusion 5-2 on the bottle mouth base 5, and the tail end of the front telescopic connecting pipe 2 is tightly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com