A Synchronous Lifting Mechanism for Automatic Die Changing of Fixtures for Auto Parts

A technology of auto parts and synchronous lifting, which is applied in the field of auto parts, can solve problems such as heavy weight, potential safety hazards, troubles, etc., and achieve the effect of improving safety and reliability and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

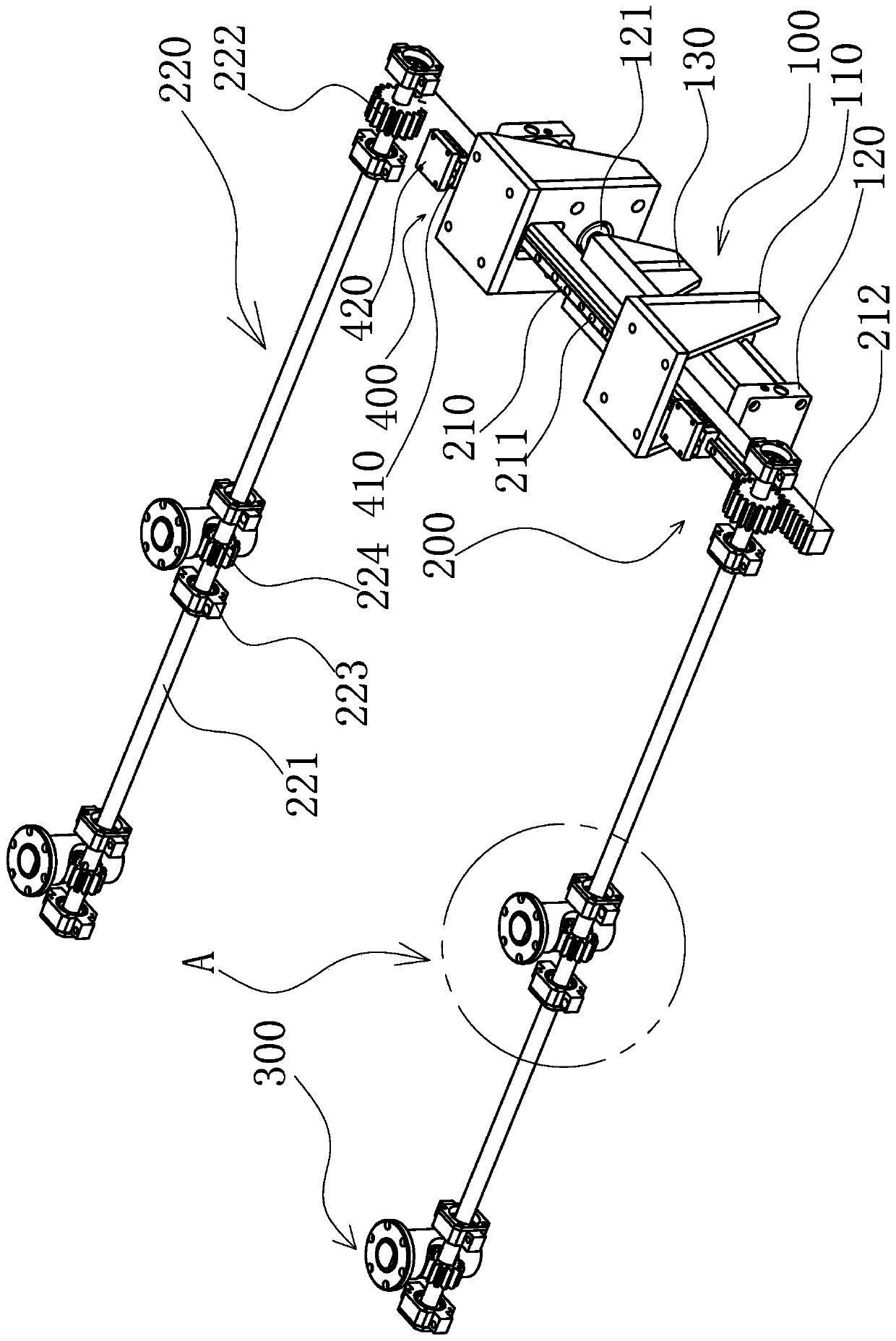

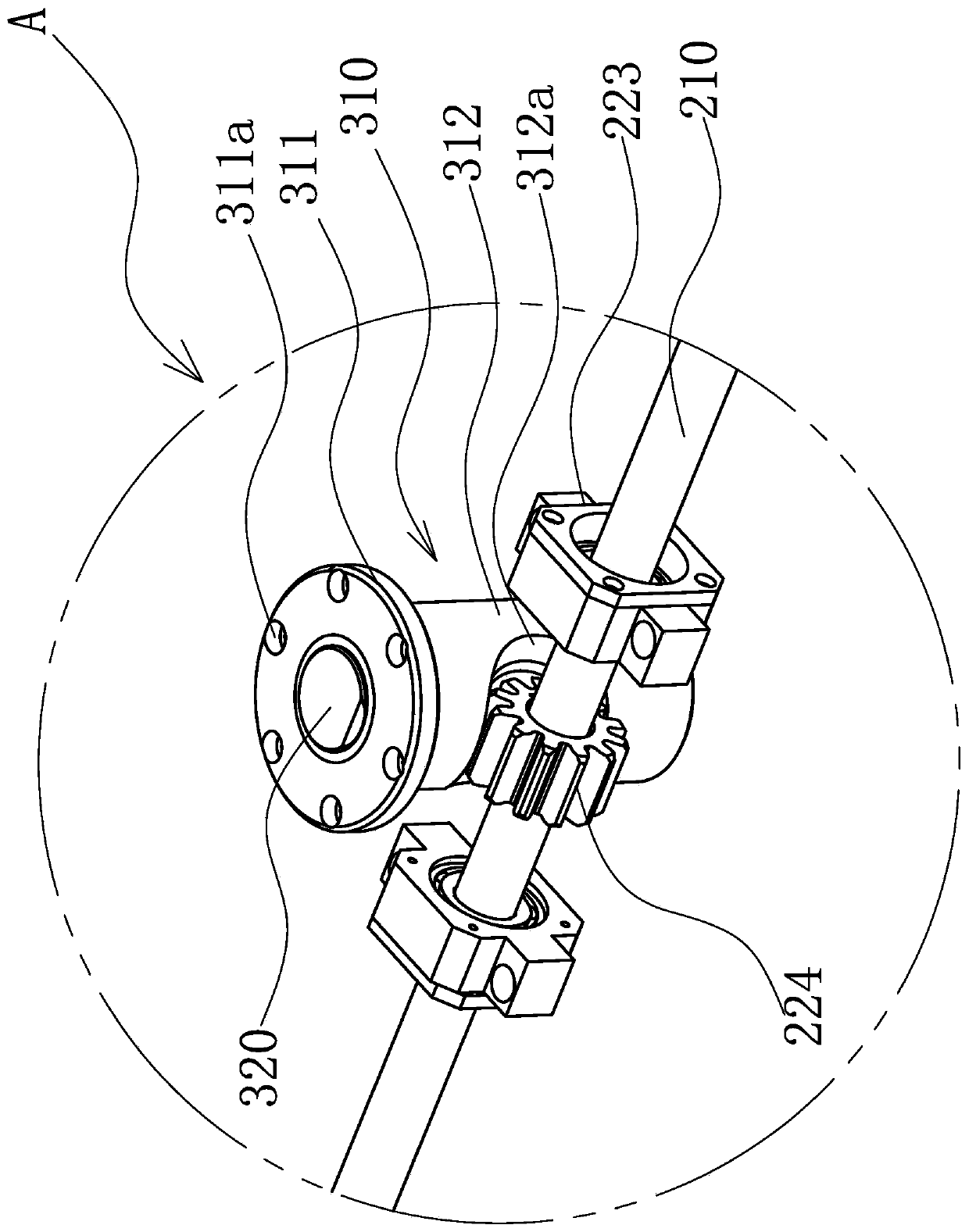

[0040] Such as figure 1 As shown, the present invention provides a synchronous elevating mechanism for automatic die-changing fixtures for auto parts, including: a power assembly 100 installed on the assembly line; a transmission assembly 200 connected to the power assembly 100 to connect the Kinetic energy is transmitted to the transmission assembly 200; at least one pair of lifting assemblies 300 are located on both sides of the transmission assembly 200 and connected with the transmission assembly 200, and the synchronous lifting and lowering of the pair of lifting assemblies 300 is realized through the transmission assembly 200.

[0041] The jig automatic mold change synchronous lifting mechanism for auto parts provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com