Reaction sticky asphalt waterproof sheet material and preparation method thereof

An asphalt waterproofing membrane, reactive sticking technology, applied in the direction of asphalt material adhesive, adhesive, adhesive type, etc., can solve the problem that the construction thickness of waterproof coating is not easy to control, the horizontal and vertical tension of waterproofing membrane is uneven, and the sealing and waterproofing are lost. effect and other issues, to achieve the effect of increasing the bonding performance and strength, improving the viscosity, and enhancing the bonding performance

Inactive Publication Date: 2017-06-06

北京朗坤防水材料有限公司

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the construction thickness of the waterproof coating is not easy to control; it is firmly combined with the base surface, and it is easily affected by cracks in the base surface to cause stretching and cracking; most coatings are not easy to use in long-term water-immersed environments, and are not easy to use in places exposed to sunlight; construction It needs to be painted many times, the construction period is long, and solvents are easily generated during the construction process, polluting the environment and other problems.

[0004] At the same time, the biggest obstacle in the use of membrane waterp

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

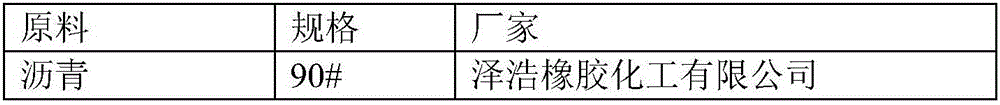

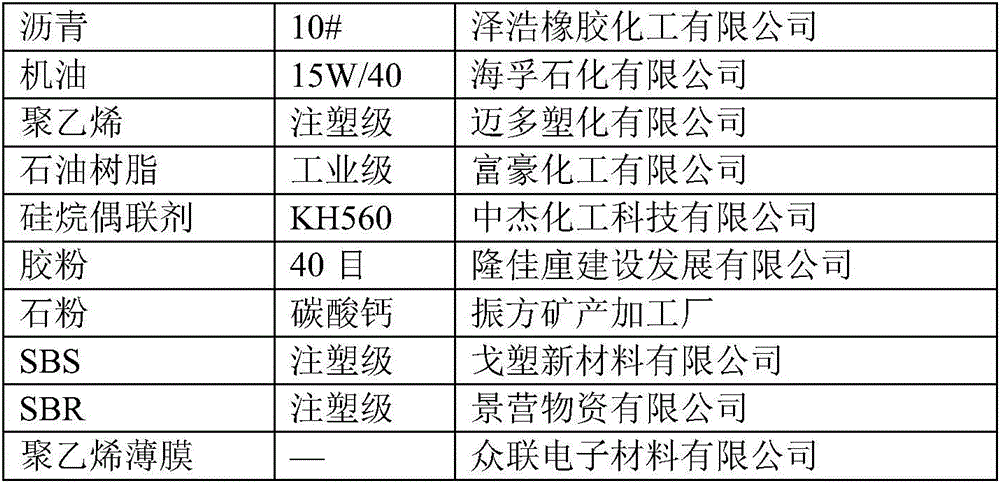

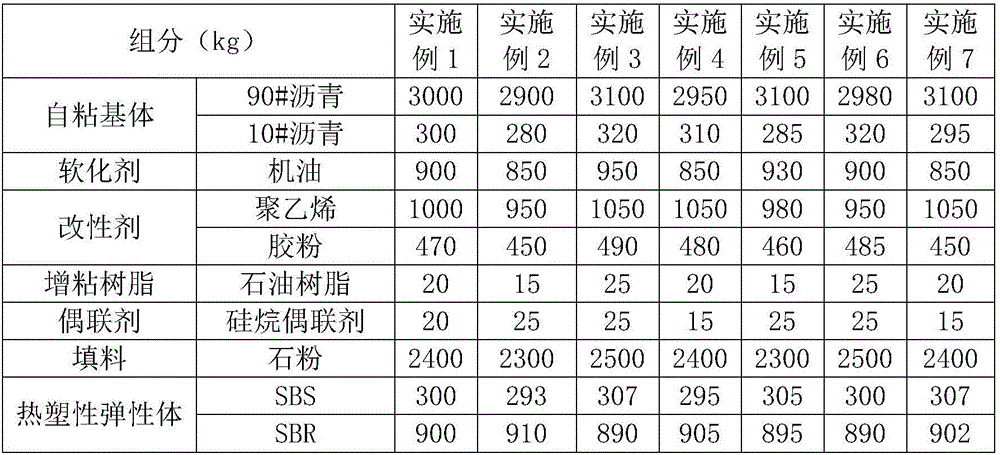

The invention relates to a reaction sticky asphalt waterproof sheet material, which comprises a first insulating film, a first reaction sticky asphalt waterproof layer, a polyurethane padding base layer, a second reaction sticky asphalt waterproof layer and a second insulating film, which are arranged from top to bottom; the first reaction sticky asphalt waterproof layer and the second reaction sticky asphalt waterproof layer are prepared from the same components in parts by weight: 2900 to 3100 parts of 90 # asphalt, 280 to 320 parts of 10 # asphalt, 850 to 950 parts of engine oil, 950 to 1050 parts of polyethylene, 15 to 25 parts of petroleum resin, 15 to 25 parts of coupling agent, 450 to 490 parts of rubber powder, 2300 to 2500 parts of stone powder, 293 to 307 parts of SBS and 890 to 910 parts of SBR. The SBS and the SBR are combined for use, and thus the sticky property of the reaction sticky asphalt waterproof sheet material is improved.

Description

technical field [0001] The invention relates to the field of building waterproof materials, more specifically, it relates to a reaction-adhesive asphalt waterproof coiled material and a preparation method thereof. Background technique [0002] At present, due to the improper selection of waterproof materials on the surface of buildings in humid environments, water seepage often occurs on the surface of the building, resulting in corrosion of steel bars inside the building, spalling of concrete pavement, alkali-aggregate reaction, and concrete expansion caused by steel bar corrosion. The damage problem seriously affects the durability of the building and the normal service life of the building. Therefore, the waterproofing of buildings, especially the waterproofing of buildings in humid environments, has attracted increasing attention. In the process of traditional building construction, waterproof materials are generally divided into two categories: coiled materials and coa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J195/00C09J123/06C09J157/02C09J133/04C09J153/02C09J109/06C09J11/04C09J11/06C09J7/02

Inventor 于春月张颢楠

Owner 北京朗坤防水材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com