Closing-in tool and closing-in structure of wall cloth

A tool and closing technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of process tank blockage and high labor cost, and achieve the effect of reducing labor cost and complete form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

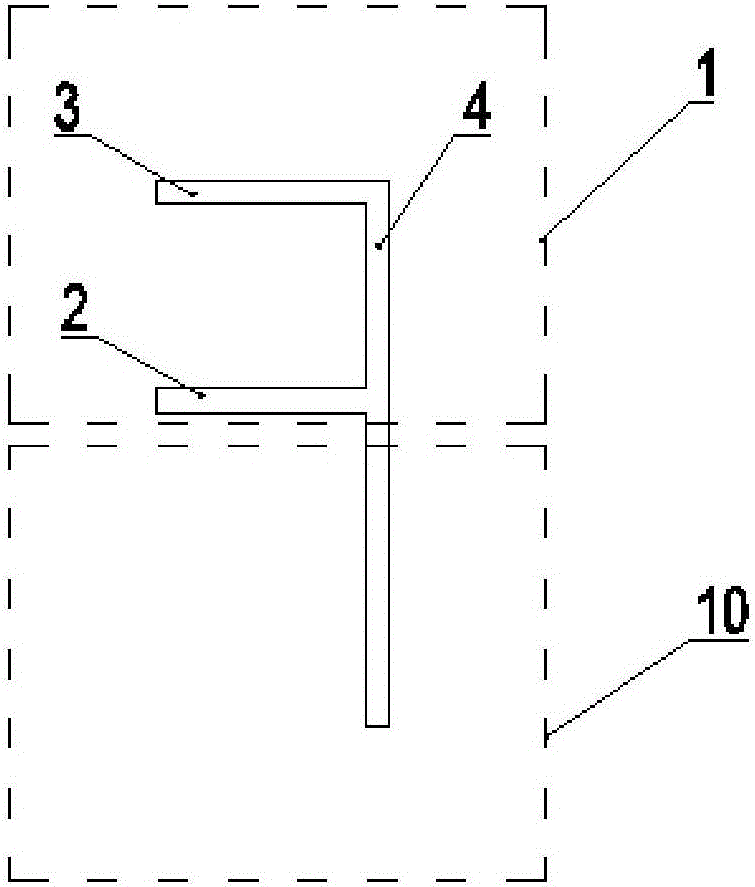

[0057] Such as figure 1 Shown is a closing tool, including a process tank stopper 1 and a process tank stopper 10, the process tank stopper 1 includes a front plate 2, a rear plate 3 and a side plate 4, the front plate 2 and the rear plate 3 are arranged in parallel, and the side plates The two ends of the plate 4 are respectively connected to the end faces of the same side of the front plate 2 and the rear plate 3;

[0058] The size of the process tank plug 1 matches the size of the process tank;

[0059] The process tank stopper 10 is connected to the side plate 4 .

[0060] The length and width of the process tank stopper 1 are 5mm, the thickness of the front plate 2, the side plate 4, the back plate 3 and the process tank stopper 10 is 1mm, and the process tank stopper 10 is 15mm long.

Embodiment 2

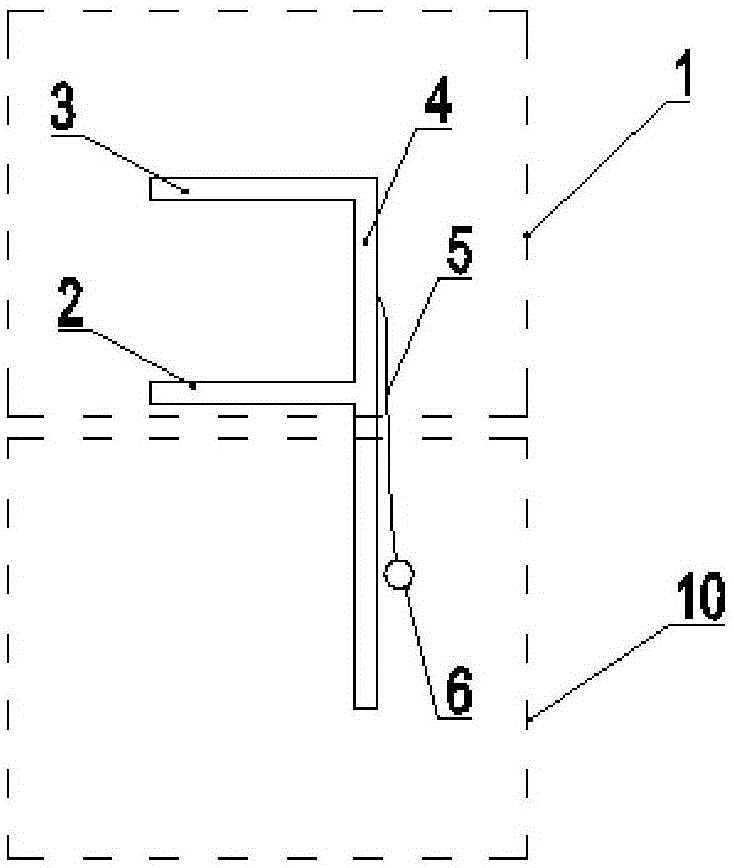

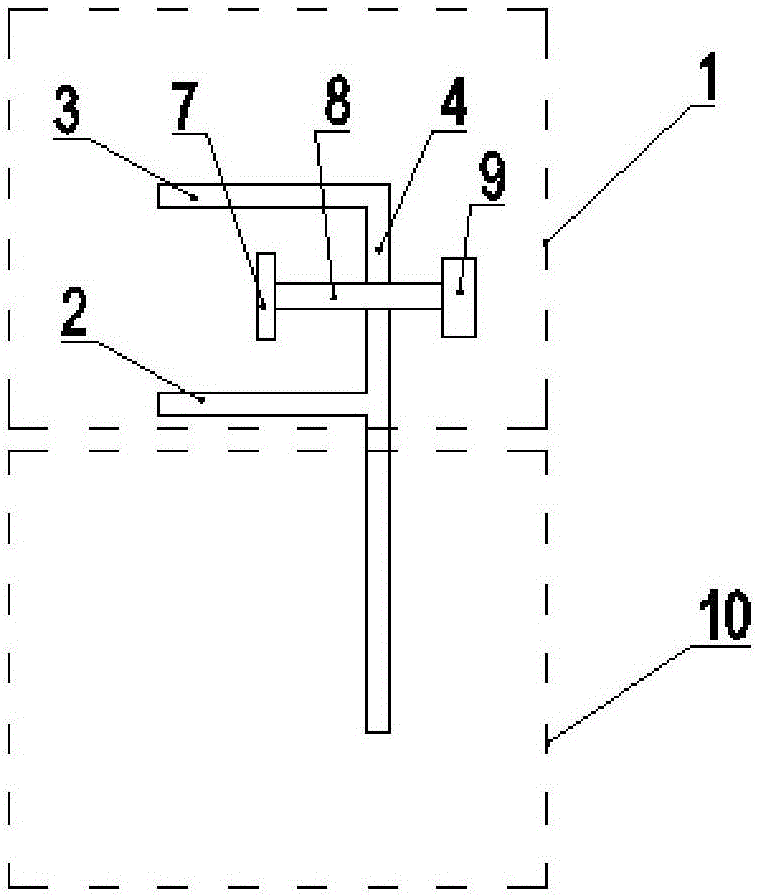

[0062] A closing structure, different from Embodiment 1, is that the side plate 4 is provided with a pull-out assembly for pulling the closing tool out of the process tank.

[0063] Such as figure 2 Shown is the first implementation of this embodiment, the pull-out assembly includes a connecting rope 5 and a pull ring 6 , and both ends of the connecting rope 5 are connected to the side plate 4 and the pull ring 6 respectively.

[0064] Such as image 3 Shown is the second implementation of this embodiment, the pull-out assembly includes a clip 7, a pull rod 8 and a handle 9, the two ends of the pull rod 8 are respectively connected to the clip 7 and the handle 9, and the pull rod 8 is inserted through the side plate 4 .

Embodiment 3

[0066] Such as Figure 4-6 Shown is a closing structure of a wall covering, which includes the closing tool described in Embodiment 1, and also includes a wood veneer 11, on which a process tank 12 is arranged, and the process tank plug 1 is arranged in the process tank 12 , The process slot stopper 10 is attached to the side wall of the wood veneer 11 .

[0067] After the putty has been approved on the wall surface 13, the above-mentioned closing tool is taken out from the process tank 12 to obtain a complete process tank 12.

[0068] Finally, the wall covering 14 is laid, and the wall covering 14 can be completely inserted into the process tank 12 to achieve the closing effect, which is beautiful and time-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com