Moisture-proof type filtering core supporting plate, air filter and engine of air filter

A support plate and filter element technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of increasing filtration resistance, affecting the filtration effect, and wetting the filter element, so as to achieve good engine performance and ensure the filtration effect , good for keeping dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

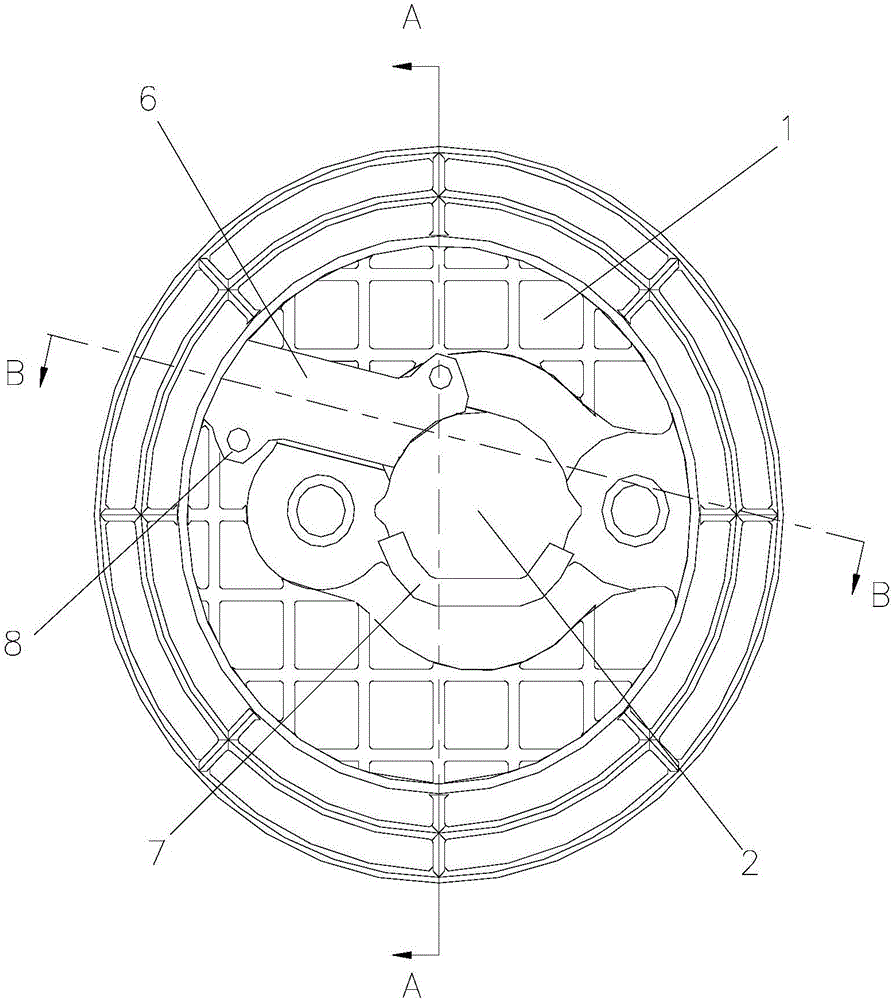

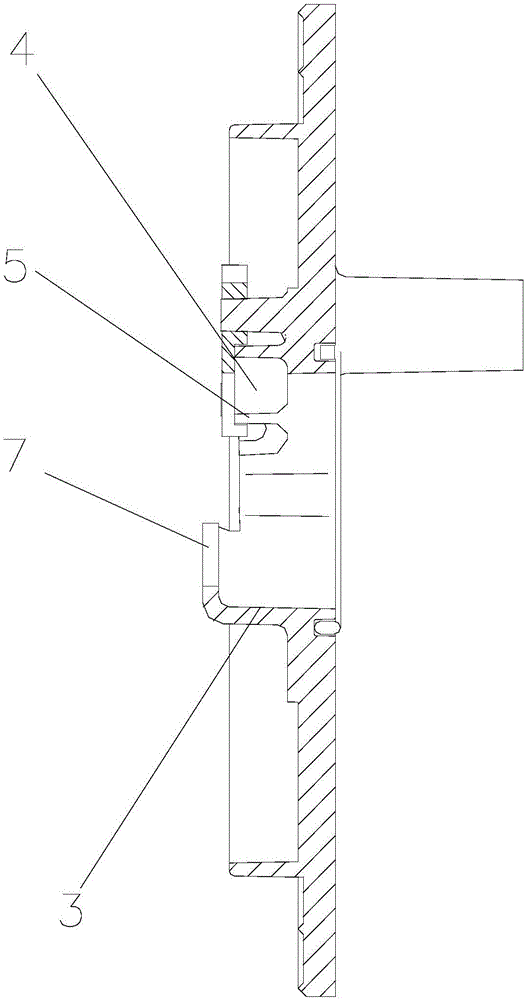

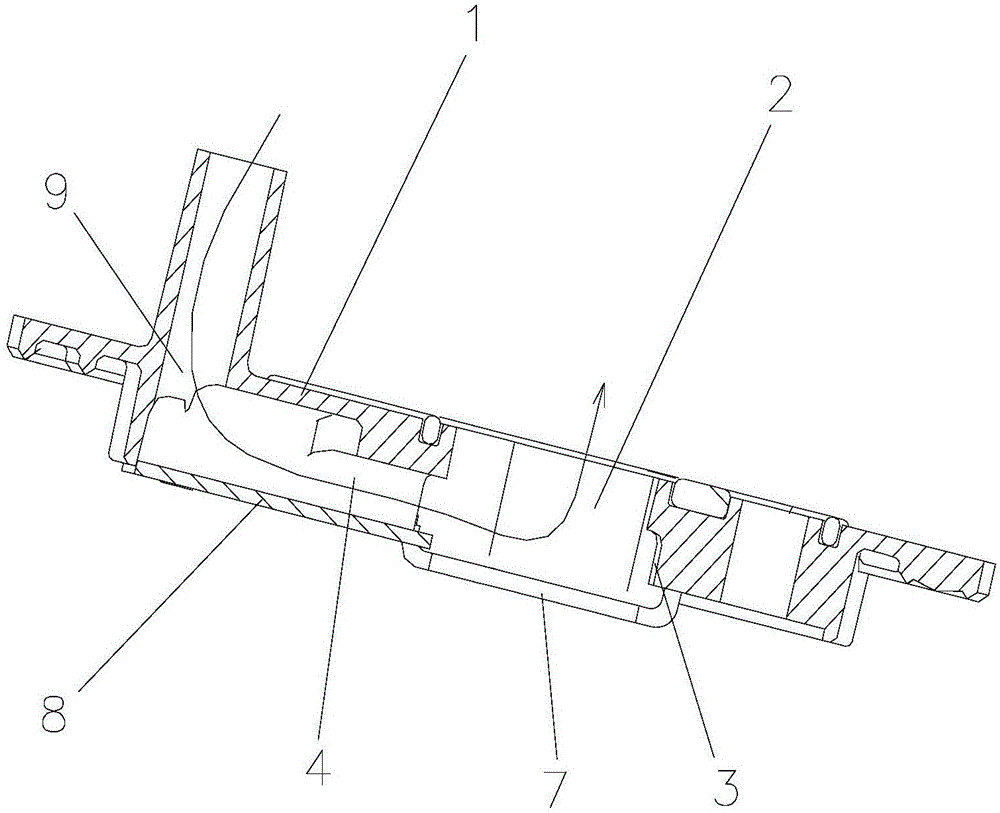

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A-A sectional view of, image 3 for figure 1 B-B sectional view, as shown in the figure, the moisture-proof filter element support plate in this embodiment; includes a support plate body 1 provided with an air outlet hole 2 and an exhaust gas inlet hole, and the exhaust gas inlet hole guides the exhaust gas through a guide channel 4 To the air outlet hole 2, the support plate body 1 is also provided with a guide part 3 for limiting the exhaust gas flowing out of the guide channel 4 to the air outlet hole 2; All the flow guide structures for the purpose, such as the guide plate or guide groove formed by the support plate body 1 itself to limit the flow of exhaust gas, through the setting of the guide part 3, prevent the exhaust gas from flowing out of the guide channel 4 from directly contacting the inside of the air filter Condensation on the surface of relatively cold par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com