Fan control system and method aiming at fan control signal state

A fan control and signal state technology, applied in the field of server heat dissipation, can solve problems such as low fan speed, impact on customer business, failures, etc., to avoid heat dissipation problems, ensure normal work, and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

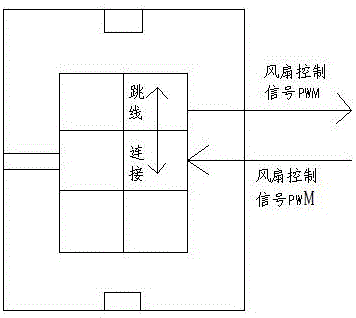

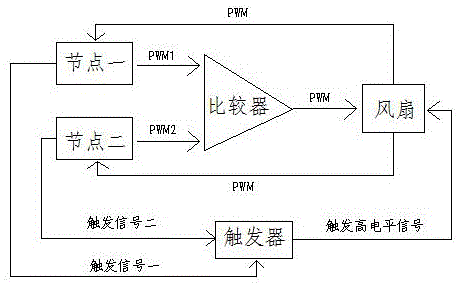

[0030] Such as figure 1 and figure 2 As shown, the fan control system for the fan control signal state of the present invention is composed of node 1, node 2, a comparator, a trigger and a fan. Node 1 and Node 2 are respectively connected to the comparator. Node 1 is used to send the PWM1 signal to the comparator, node 2 is used to send the PWM2 signal to the comparator, the comparator compares PWM1 and PWM2, and obtains a larger value as the fan control signal PWM. The fan is connected to the comparator, node 1, and node 2 respectively. Two adjacent fan control signal pins on the fan terminal pins are connected by a jumper. The internal control programs of node 1 and node 2 respectively add fan control signal recognition algorithms. The fan control signal PWM obtained by the comparator is used to control the fan, and the fan control signal PWM is sent back to node 1 and node 2. Node 1 and Node 2 judge the rationality of the fan control signal PWM through the fan control...

Embodiment 2

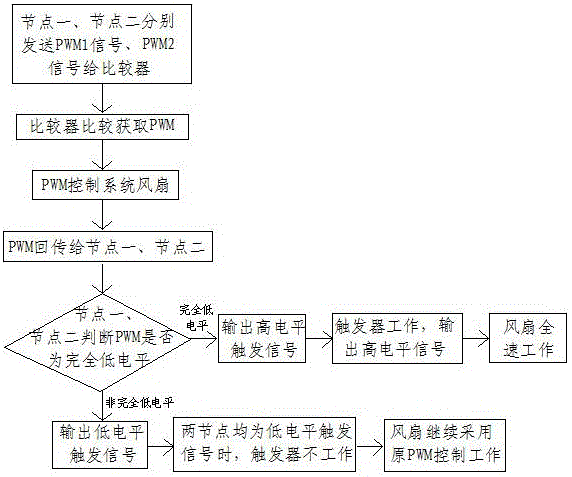

[0032] Such as image 3 As shown, in the fan control method for the fan control signal state of the present invention, nodes 1 and 2 send the PWM1 signal and PWM2 signal to the comparator, and the comparator compares the PWM1 signal and PWM2 signal to obtain a larger value as the fan control Signal PWM to control the fan. At the same time, the fan control signal PWM is sent back to node 1 and node 2. Node 1 and node 2 respectively identify the rationality of the fan control signal PWM through the internal fan control signal identification algorithm, and output trigger signal 1 and trigger signal respectively according to the judgment results. Two, send to the trigger. When it is recognized that the fan control signal PWM is completely low level, the fan control is abnormal, and at least one of the trigger signal 1 and trigger signal 2 output by node 1 and node 2 is a high level trigger signal and sent to the trigger, and the trigger works and outputs high power. Ping signal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com