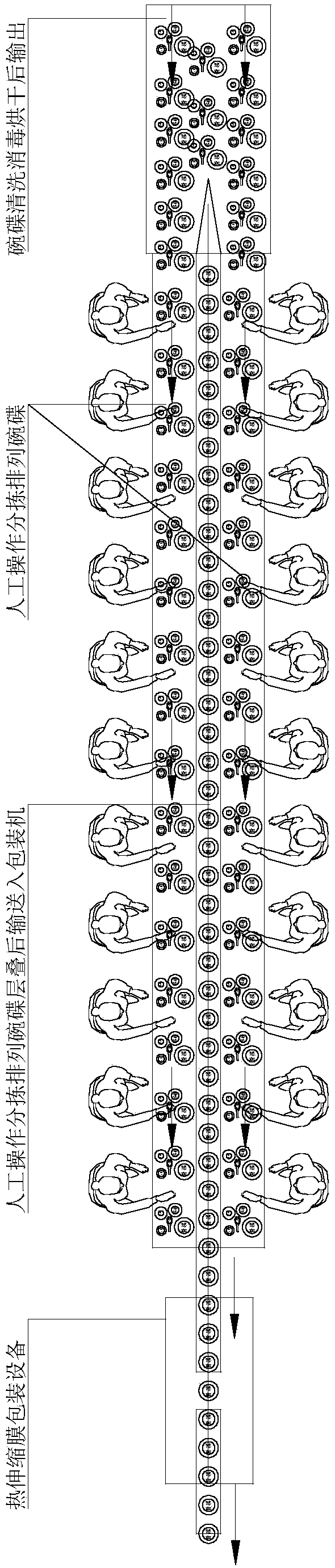

A fully automatic vertical dish bowl cup confluence conveying equipment and its application method

A conveying equipment, fully automatic technology, applied in packaging and other directions, can solve the problems of fast or slow or less and leakage of soup bowls, rice bowls, tea cups, glass water cups, work efficiency cannot be improved, large human resources, etc., to save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

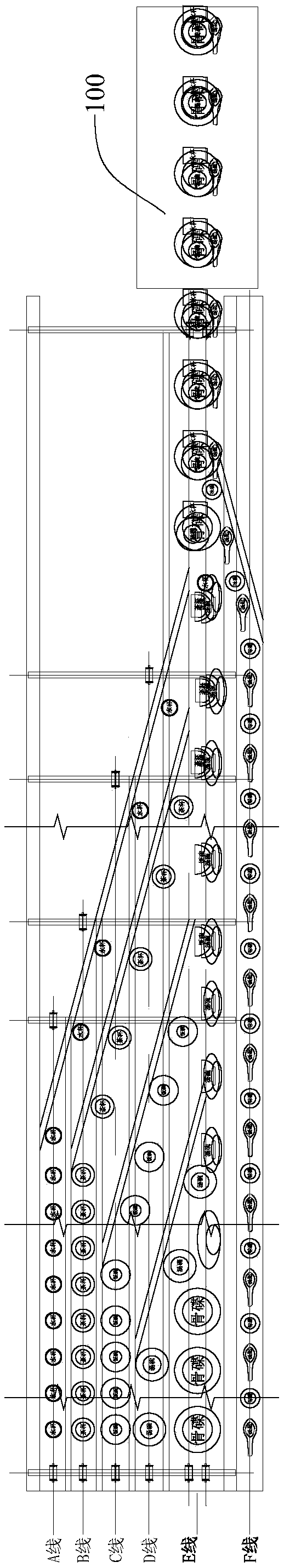

[0033] refer to Figure 2 to Figure 6 , a fully automatic vertical dishes and cups confluence conveying equipment, comprising a plurality of conveying lines for conveying the dishes and cups, and the plurality of conveying lines are merged into one conveying line at the tail end of one of the conveying lines.

[0034] The plurality of said conveying lines includes A-line for conveying water cups; B-line for conveying teacups; C-line for conveying rice bowls; D-line for conveying soup bowls; E-line for conveying bone dishes; Line F is used to convey spoons and saucers; Line A, Line B, Line C, Line D, and Line F merge at the end of Line E, and teacups, rice bowls, soup bowls, bone saucers, water cups, spoons and saucers are stacked vertically.

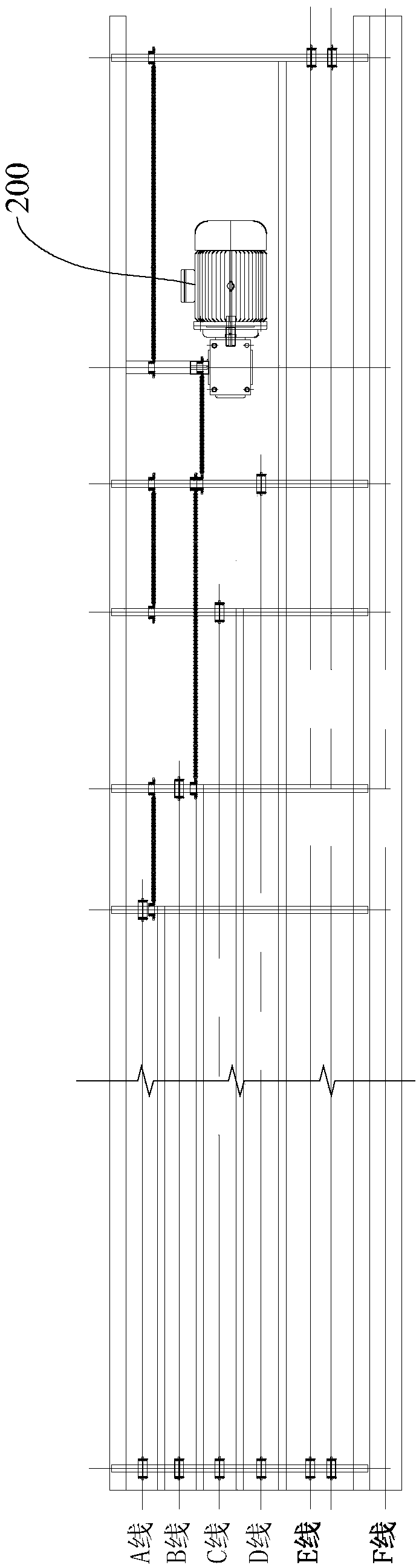

[0035] The A-line, B-line, C-line, D-line and F-line all include a straight conveyor belt and an inclined conveyor belt at an angle of 10°-35° with the straight conveyor belt to cut into the E-line.

[0036] Both the straight line conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com