Multi-steam-source steam spraying heat pump

A steam and heat pump technology, used in jet pumps, pumps, non-displacement pumps, etc., can solve the problem of large flow loss of low-pressure inlet steam and can not meet more than two different parameters (pressure, temperature, etc., to increase heat supply , Improve the utilization rate of heat energy, improve the effect of adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

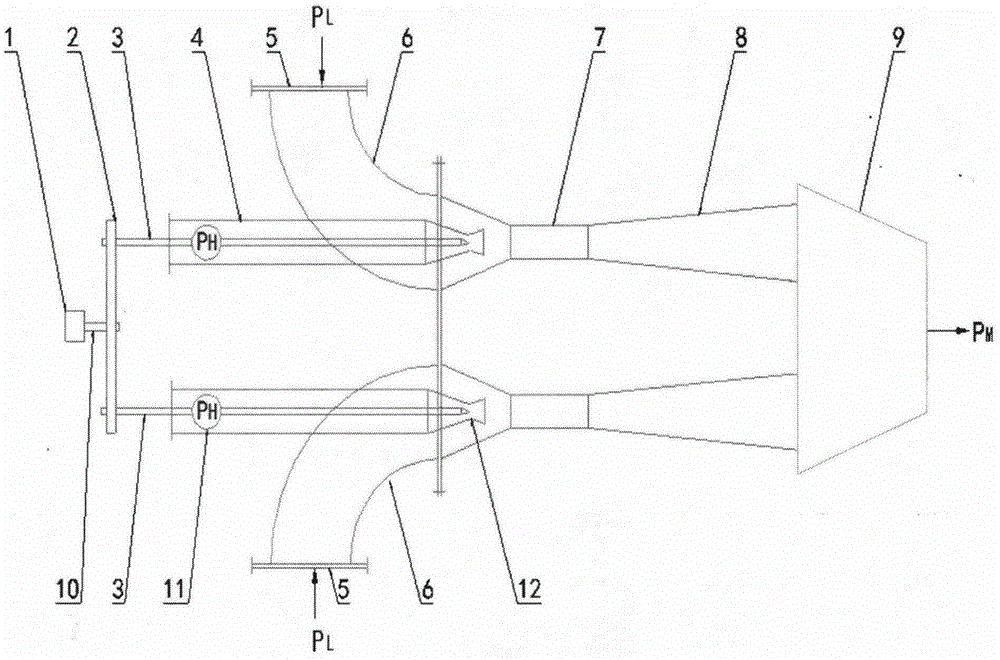

[0014] Such as figure 1 As shown, this multi-steam source injection heat pump is provided with a driving steam chamber 4, a suction chamber 6, a mixing chamber 7 and an expansion chamber 8. The suction chamber 6 is provided with a suction steam inlet 5, and the gap between the driving steam chamber 4 and the suction chamber 6 is Nozzles 12 are provided, and each nozzle 12 is correspondingly provided with a mixing chamber 7 and an expansion chamber 8, and each nozzle 12 is correspondingly provided with a valve stem 3, and the driving steam chamber 4 is composed of two or more small steam chambers, each A small steam chamber is provided with an independent drive steam inlet 11, and a needle-shaped valve core is arranged in the nozzle 12, and each needle-shaped valve core is connected with a needle-shaped valve stem 3. The needle-shaped valve stem 3 extends out of the driving steam chamber 4 and connects with the valve stem connector 2, the valve stem connector 2 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com