multi-way valve

A multi-way reversing valve and reversing valve technology, which is applied in the field of hydraulic valves, can solve the problems of poor controllability and insignificant energy-saving effect of multi-way reversing valves, and achieve the advantages of reducing energy loss, improving work efficiency and improving controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation will be described below in conjunction with the accompanying drawings.

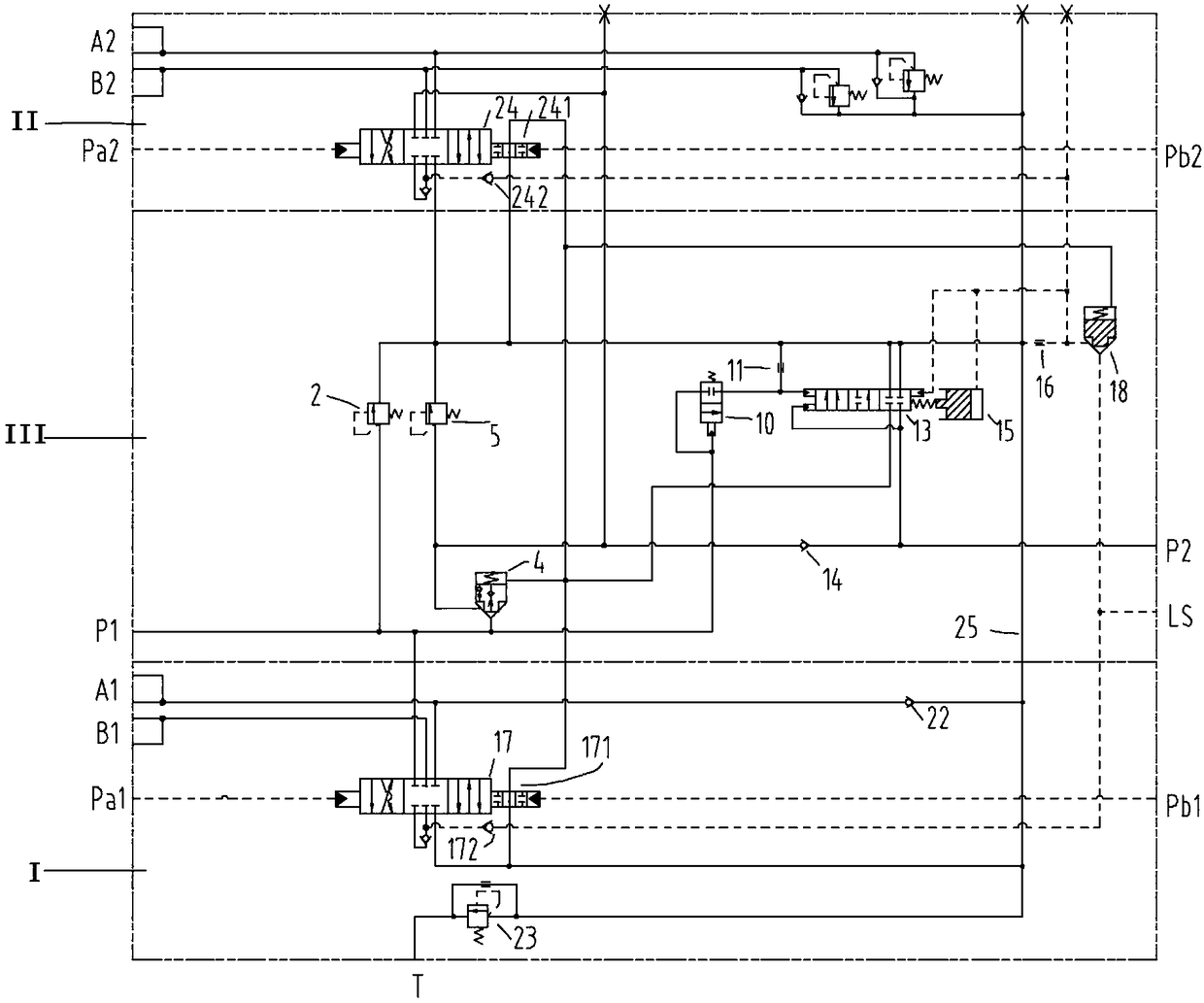

[0026] Such as Figure 1 to Figure 4 As shown, the multi-way reversing valve in this embodiment includes a first reversing module I, a second reversing module II and a confluence module III.

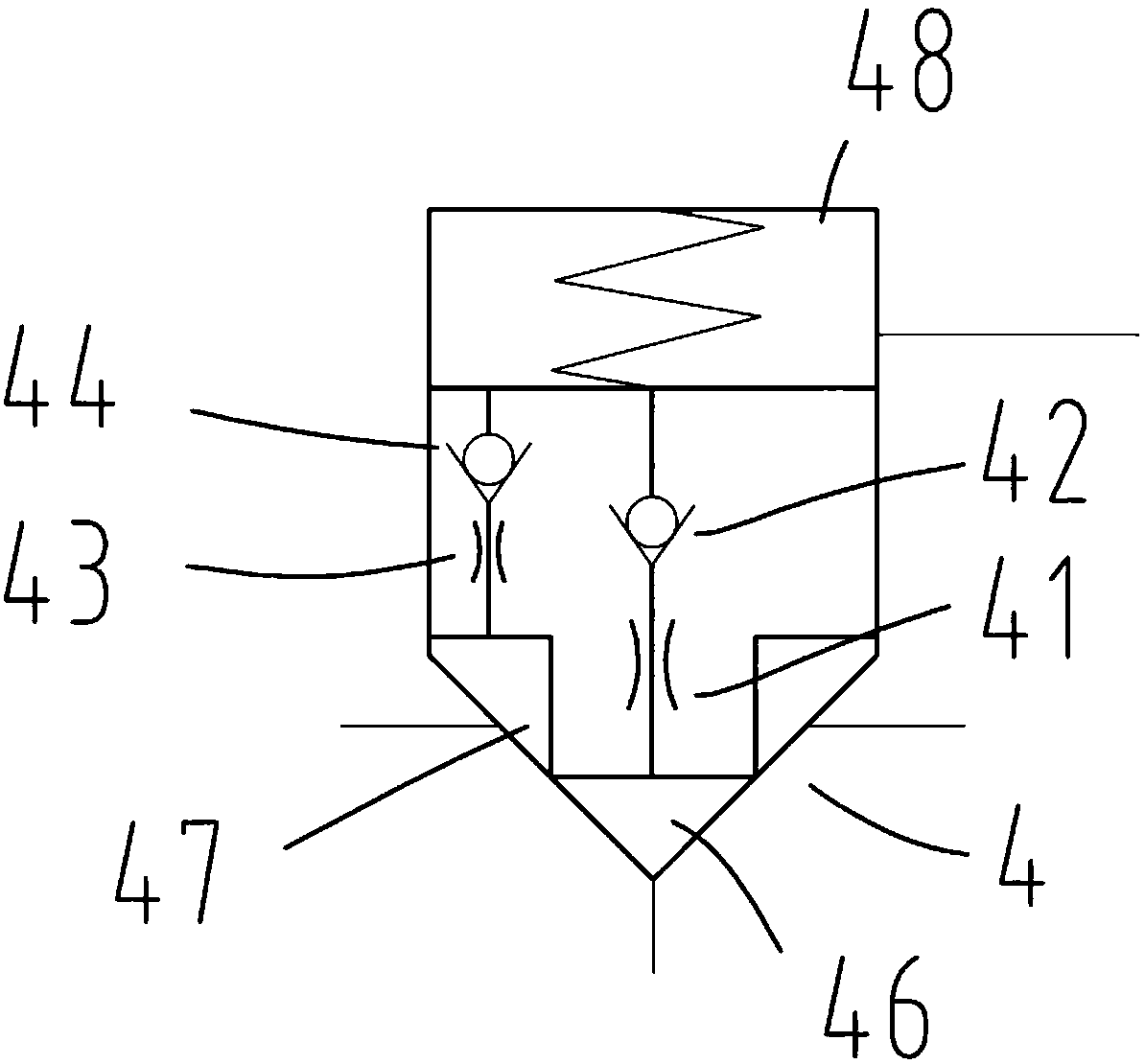

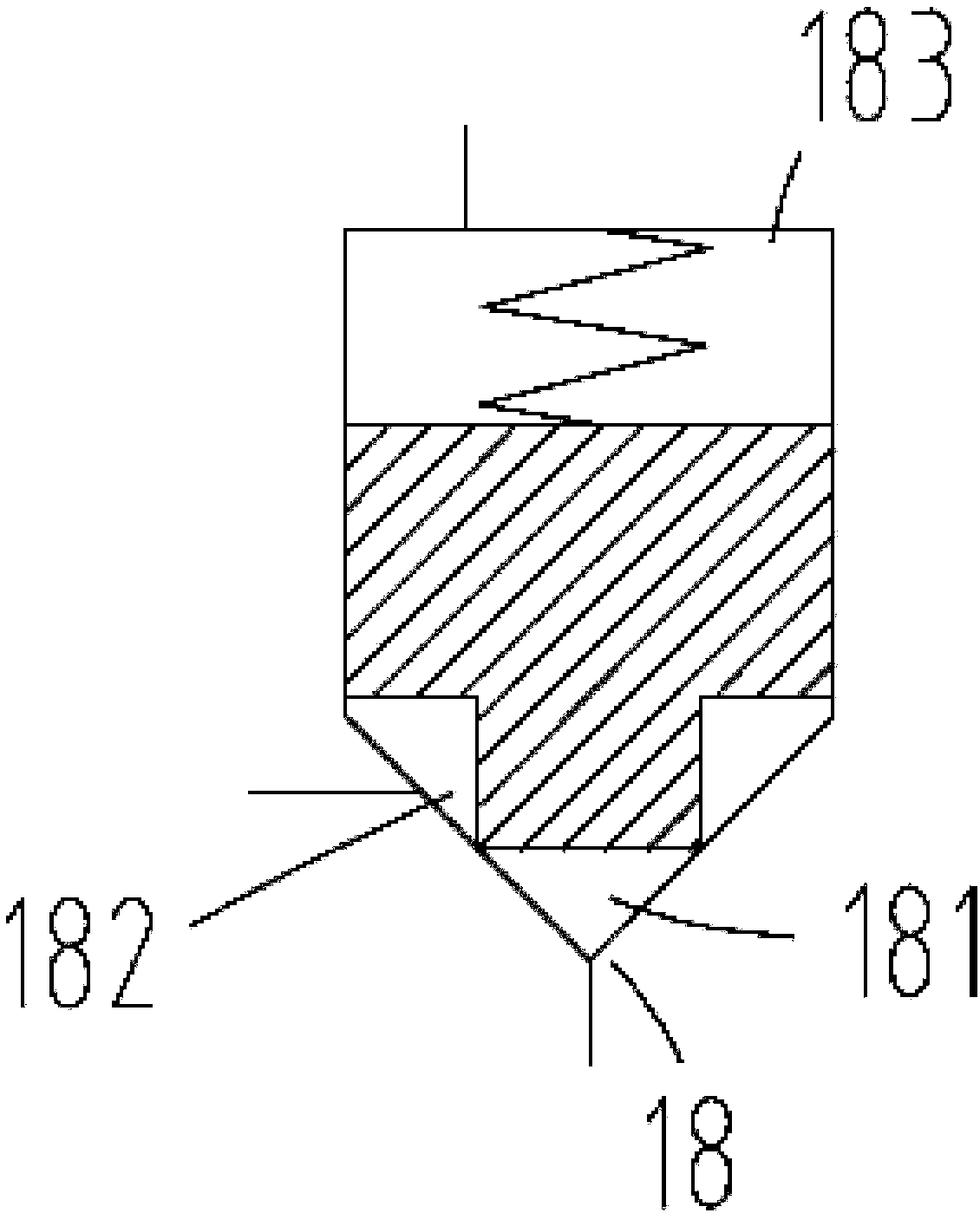

[0027] The first reversing module 1 is used in the hydraulic system to control the first hydraulic actuator, for example, in the loader hydraulic system to control the boom cylinder. The first reversing module 1 includes a first reversing module reversing valve 17 and a first switching valve 171 synchronously linked with the first reversing module reversing valve 17, and the first reversing module reversing valve 17 is a neutral function. O-type three-position six-way reversing valve, the first switching valve 171 is a three-position two-way valve. Both ends of the spool of the first reversing module reversing valve 17 respectively have a Pa1 pilot control oil port and a Pb1 pilo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com